The top three susceptor silicon carbide TaC products include the TaC Coated Wafer Susceptor, TaC Coated Planetary Susceptor, and TaC Coated MOCVD Graphite Susceptor. These products play a crucial role in semiconductor manufacturing and other high-temperature applications. Their significance lies in their ability to maintain consistent Si concentration, ensuring high-quality outputs. The selection of these products is based on criteria such as durability, thermal stability, and industry relevance. SiC-coated graphite susceptors and MOCVD susceptors with TaC coating exemplify the advanced technology in TaC-coated susceptors, offering unmatched performance in demanding environments.

Key Takeaways

- The TaC Coated Wafer Susceptor ensures uniform heat distribution, crucial for high-quality semiconductor layer production.

- Durability and thermal efficiency of TaC coated susceptors lead to reduced maintenance costs and improved operational efficiency.

- The TaC Coated Planetary Susceptor is cost-effective, offering energy savings and longevity, making it ideal for semiconductor manufacturing.

- Exceptional resistance to corrosion in TaC Coated MOCVD Graphite Susceptors extends their lifespan and reduces maintenance needs.

- These susceptors are not only vital in semiconductor manufacturing but also find applications in aerospace, automotive, and energy sectors.

- Selecting the right TaC coated susceptor is essential for achieving optimal performance in high-temperature environments.

- Investing in TaC coated susceptors enhances reliability and efficiency, supporting innovation across various industries.

Product 1: TaC Coated Wafer Susceptor

Features

Material Composition

The TaC Coated Wafer Susceptor features a robust graphite core enveloped in a layer of tantalum carbide. This combination ensures the susceptor can withstand extreme temperatures and corrosive environments typical in semiconductor manufacturing. The tantalum carbide coating provides exceptional thermal stability, making it an ideal choice for high-temperature applications.

Design and Structure

The design of the TaC Coated Wafer Susceptor focuses on uniform heat distribution. Its structure allows for consistent temperature control, which is crucial for the reproducibility of semiconductor layers during the Metal-Organic Chemical Vapor Deposition (MOCVD) process. The susceptor’s design also facilitates efficient material deposition, enhancing the quality of the semiconductor layers produced.

Benefits

Durability and Longevity

The TaC Coated Wafer Susceptor offers remarkable durability due to its advanced material composition. The tantalum carbide coating protects the graphite core, extending the susceptor’s lifespan even under rigorous operational conditions. This durability translates into reduced maintenance costs and increased operational efficiency for semiconductor manufacturers.

Thermal Efficiency

Thermal efficiency is a standout feature of this susceptor. The tantalum carbide coating ensures excellent heat retention and distribution, which is vital for maintaining consistent processing conditions. This efficiency not only improves the quality of the semiconductor layers but also enhances the overall performance of the manufacturing process.

Applications

Semiconductor Industry

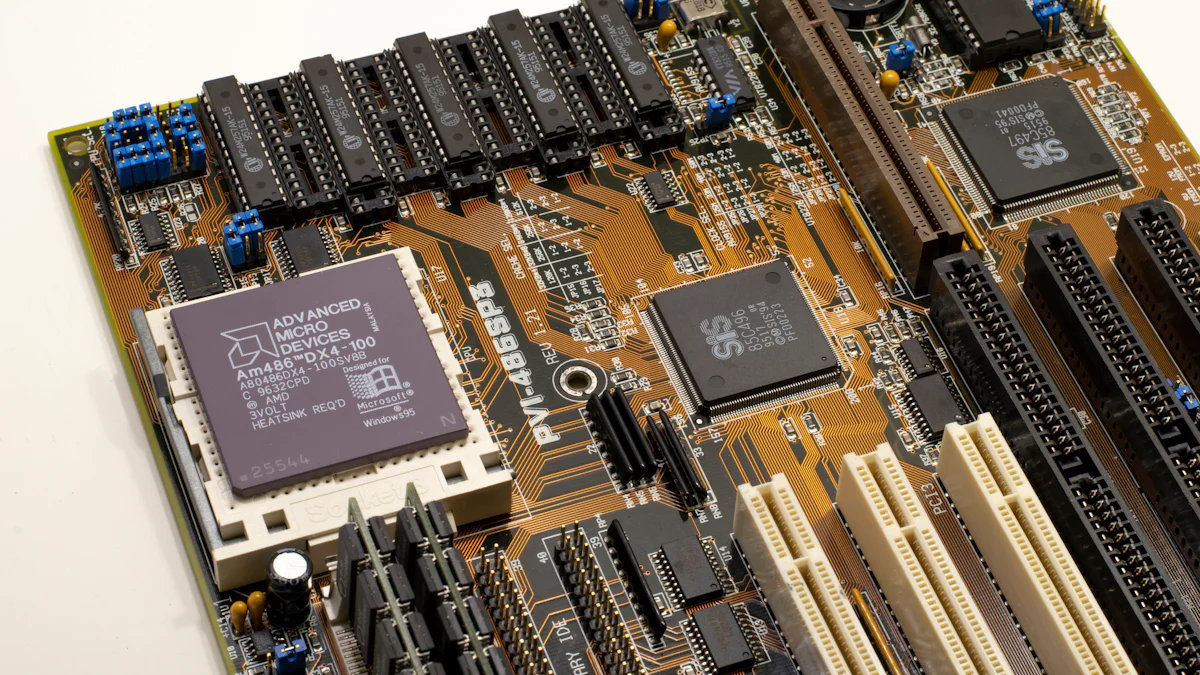

In the semiconductor industry, the TaC Coated Wafer Susceptor plays a pivotal role. It supports the epitaxial growth process, ensuring high-quality semiconductor layers. Its ability to maintain consistent Si concentration around the wafer makes it indispensable for producing advanced electronic devices.

Aerospace Industry

Beyond semiconductors, the aerospace industry also benefits from the use of TaC Coated Wafer Susceptors. Their high thermal stability and durability make them suitable for applications involving extreme temperatures and demanding conditions. These susceptors contribute to the development of advanced aerospace components, supporting innovation and excellence in the field.

Product 2: TaC Coated Planetary Susceptor

Features

Material Composition

The TaC Coated Planetary Susceptor integrates high-purity graphite with a tantalum carbide coating. This combination offers exceptional thermal, chemical, and mechanical properties. The tantalum carbide layer enhances the susceptor’s ability to withstand extreme temperatures and corrosive environments, making it indispensable in semiconductor manufacturing. The graphite core provides excellent thermal conductivity, ensuring efficient heat transfer during the epitaxial growth process.

Design and Structure

The design of the TaC Coated Planetary Susceptor focuses on uniform heating and efficient material deposition. Its structure allows for precise temperature control, which is crucial for producing high-quality epitaxial layers. The susceptor’s advanced engineering supports rapid heating and cooling cycles, optimizing production processes and improving semiconductor device performance.

Benefits

Cost-effectiveness

The TaC Coated Planetary Susceptor stands out for its cost-effectiveness. Its durability reduces the need for frequent replacements, lowering maintenance costs. The susceptor’s efficient thermal performance also contributes to energy savings, making it an economically advantageous choice for semiconductor manufacturers.

Performance in High-Temperature Environments

Performance in high-temperature environments is a key benefit of the TaC Coated Planetary Susceptor. The tantalum carbide coating ensures stability and reliability under extreme conditions, maintaining consistent performance throughout the manufacturing process. This capability enhances the quality and yield of semiconductor devices, supporting the industry’s pursuit of innovation and excellence.

Applications

Automotive Industry

In the automotive industry, the TaC Coated Planetary Susceptor plays a vital role. Its ability to withstand high temperatures and corrosive environments makes it suitable for applications in advanced automotive electronics. The susceptor supports the development of components that require precise thermal management and durability.

Energy Sector

The energy sector also benefits from the TaC Coated Planetary Susceptor. Its exceptional thermal and chemical properties make it ideal for use in energy-related applications, such as power electronics and renewable energy systems. The susceptor’s performance in high-temperature environments ensures reliability and efficiency, contributing to the advancement of energy technologies.

Product 3: TaC Coated MOCVD Graphite Susceptor

Features

Material Composition

The TaC Coated MOCVD Graphite Susceptor features a high-purity graphite substrate enveloped in a tantalum carbide coating. This combination ensures exceptional thermal stability and conductivity, making it ideal for high-temperature applications. The tantalum carbide layer acts as a protective shield, enhancing the susceptor’s resistance to corrosive gases and harsh chemical environments encountered during epitaxial growth processes.

Design and Structure

The design of the TaC Coated MOCVD Graphite Susceptor focuses on optimizing heat distribution and material deposition. Its structure supports uniform temperature control, which is crucial for the reproducibility of semiconductor layers. The susceptor’s engineering allows for rapid heating and cooling cycles, improving the efficiency and quality of the MOCVD process.

Benefits

Resistance to Corrosion

The tantalum carbide coating provides the TaC Coated MOCVD Graphite Susceptor with outstanding resistance to corrosion. This feature extends the lifespan of the susceptor by protecting the graphite core from corrosive process gases. As a result, the susceptor maintains its integrity and performance over extended periods, reducing maintenance requirements and costs.

Enhanced Mechanical Properties

The mechanical properties of the TaC Coated MOCVD Graphite Susceptor are significantly enhanced by the tantalum carbide layer. This coating increases the hardness and durability of the susceptor, allowing it to withstand the mechanical stresses of high-temperature environments. The enhanced mechanical properties contribute to the susceptor’s reliability and longevity, making it a valuable asset in semiconductor manufacturing.

Applications

Chemical Processing

In chemical processing, the TaC Coated MOCVD Graphite Susceptor plays a vital role. Its resistance to corrosive environments and high thermal stability make it suitable for applications involving aggressive chemicals and extreme temperatures. The susceptor supports the production of high-quality chemical products by ensuring consistent processing conditions.

Industrial Manufacturing

The TaC Coated MOCVD Graphite Susceptor is also essential in industrial manufacturing. Its ability to maintain uniform heat distribution and resist chemical attacks makes it ideal for producing advanced materials and components. The susceptor’s performance in demanding environments enhances the efficiency and quality of industrial manufacturing processes.

The top three susceptor silicon carbide TaC products—TaC Coated Wafer Susceptor, TaC Coated Planetary Susceptor, and TaC Coated MOCVD Graphite Susceptor—demonstrate exceptional features such as durability, thermal stability, and industry relevance. Selecting the right product for specific industrial applications is crucial for achieving optimal performance and efficiency. These products offer significant advantages in semiconductor manufacturing and other high-temperature environments. Their advanced engineering and material composition ensure long-lasting performance, making them a valuable investment for industries seeking reliable and efficient solutions.

FAQ

What is a TaC Coated Graphite Susceptor?

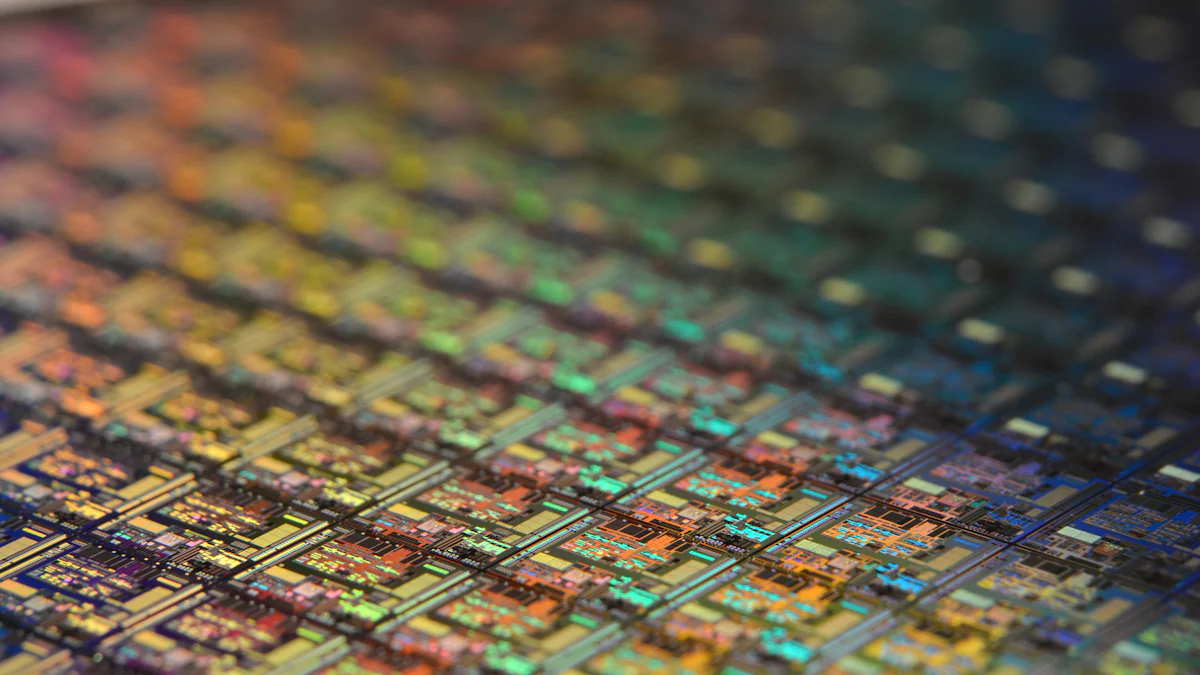

A TaC coated graphite susceptor is a material used in chemical vapor deposition (CVD) processes. It plays a crucial role in the production of semiconductors and ceramics. The susceptor consists of a high-purity graphite substrate coated with tantalum carbide, which provides excellent thermal stability and conductivity.

Why is TaC Coating Important in Semiconductor Manufacturing?

The primary purpose of the TaC coating is to enhance the performance and durability of the susceptor during semiconductor fabrication. Tantalum carbide is known for its exceptional hardness, high melting point, and resistance to wear and corrosion. These properties protect the underlying graphite susceptor from chemical reactions and physical stresses within the MOCVD furnace.

How Does the TaC Coated Wafer Susceptor Improve Semiconductor Quality?

The TaC Coated Wafer Susceptor ensures consistent and uniform heat distribution. This feature contributes to the reproducibility and quality of semiconductor layers grown during the MOCVD process. The advanced material combination of graphite and tantalum carbide makes it a reliable solution for semiconductor manufacturing.

What Are the Applications of TaC Coated Graphite Susceptors?

TaC coated graphite susceptors are primarily used in processes such as epitaxy, single crystal growth, and MOCVD. Their excellent thermal conductivity and stability make them advantageous as components of MOCVD equipment. The shape of these susceptors can vary, with disc susceptors mainly used for epitaxy and barrel susceptors for single crystal growth.

How Does TaC Coating Enhance the Performance of Graphite Surfaces?

In semiconductor manufacturing, even small improvements can significantly impact performance, durability, and efficiency. TaC coating on graphite surfaces enhances these aspects by providing a protective layer that withstands high temperatures and corrosive environments. This advancement is gaining attention in the industry for its ability to improve manufacturing outcomes.

What Are the Key Benefits of Using TaC Coated Susceptors?

TaC coated susceptors offer several benefits, including high thermal stability, excellent conductivity, and resistance to corrosion. These properties ensure the susceptor’s longevity and reliability in demanding environments, making them ideal for high-temperature applications in semiconductor and ceramic production.

Can TaC Coated Susceptors Be Used in Other Industries?

Yes, TaC coated susceptors find applications beyond semiconductors. Industries such as aerospace, automotive, and energy sectors benefit from their high thermal stability and durability. These susceptors support the development of advanced components that require precise thermal management and resistance to harsh conditions.

How Are TaC Coated Graphite Susceptors Manufactured?

Manufacturers prepare TaC coated graphite susceptors using a wet ceramic process. This method involves coating tantalum carbide on a high-purity graphite substrate. The resulting product exhibits high purity, excellent thermal stability, and conductivity, making it suitable for various high-temperature applications.

What Makes TaC Coated Susceptors a Reliable Investment?

The advanced engineering and material composition of TaC coated susceptors ensure long-lasting performance. Their durability reduces maintenance costs and enhances operational efficiency, making them a valuable investment for industries seeking reliable and efficient solutions in high-temperature environments.