Quartz chambers are essential in scientific instruments, providing stable environments that guarantee precise measurements. The exceptional thermal stability of a quartz chamber minimizes the effects of temperature fluctuations, while its optical clarity ensures accurate data collection across various wavelengths. Unlike other materials, quartz chambers resist chemical reactions and environmental wear, making them perfect for demanding applications. For example, studies comparing gray quartz chambers to sapphire chambers demonstrate that quartz offers superior performance, including faster cooling times and consistent results. Whether in spectroscopy, advanced material research, or specific locations like quartz chambers Newcastle, a quartz chamber nearby delivers unparalleled reliability and precision.

Key Takeaways

- Quartz chambers provide exceptional thermal stability, ensuring consistent performance even in extreme temperature variations, which is crucial for precision in scientific measurements.

- The optical clarity of quartz allows for accurate light transmission across various wavelengths, enhancing the reliability of spectroscopic and optical applications.

- Quartz chambers are highly resistant to chemical reactions, making them ideal for use in environments with harsh substances, thus maintaining the integrity of scientific processes.

- Their mechanical strength and durability reduce wear and tear, leading to long-lasting performance and lower maintenance costs in demanding applications.

- Quartz chambers are versatile and adaptable, making them suitable for a wide range of fields, including semiconductor manufacturing, medical diagnostics, and environmental monitoring.

- Investing in quartz chambers may have a higher initial cost, but their long-term reliability and efficiency make them a cost-effective choice for precision-driven industries.

- Emerging technologies, such as AI and nanotechnology, are enhancing the capabilities of quartz chambers, driving innovation in fields like quantum computing and advanced material research.

Unique Properties of Quartz Chambers

Thermal Stability

Resistance to temperature fluctuations

Quartz chambers excel in maintaining stability under extreme temperature variations. Their ability to resist thermal shocks ensures consistent performance, even in demanding environments. This property makes them indispensable in processes like chemical vapor deposition (CVD) and etching, where precise temperature control is critical. Unlike other materials, quartz minimizes the risk of thermal stress, preserving the integrity of scientific tools during high-temperature operations.

Minimal thermal expansion for consistent performance

The low thermal expansion coefficient of quartz ensures dimensional stability, even when exposed to significant temperature changes. This characteristic is vital for applications requiring precision, such as semiconductor manufacturing and photolithography. Quartz chambers maintain their shape and functionality, enabling accurate measurements and reliable results. Their exceptional thermal stability supports long-term use in environments with fluctuating temperatures.

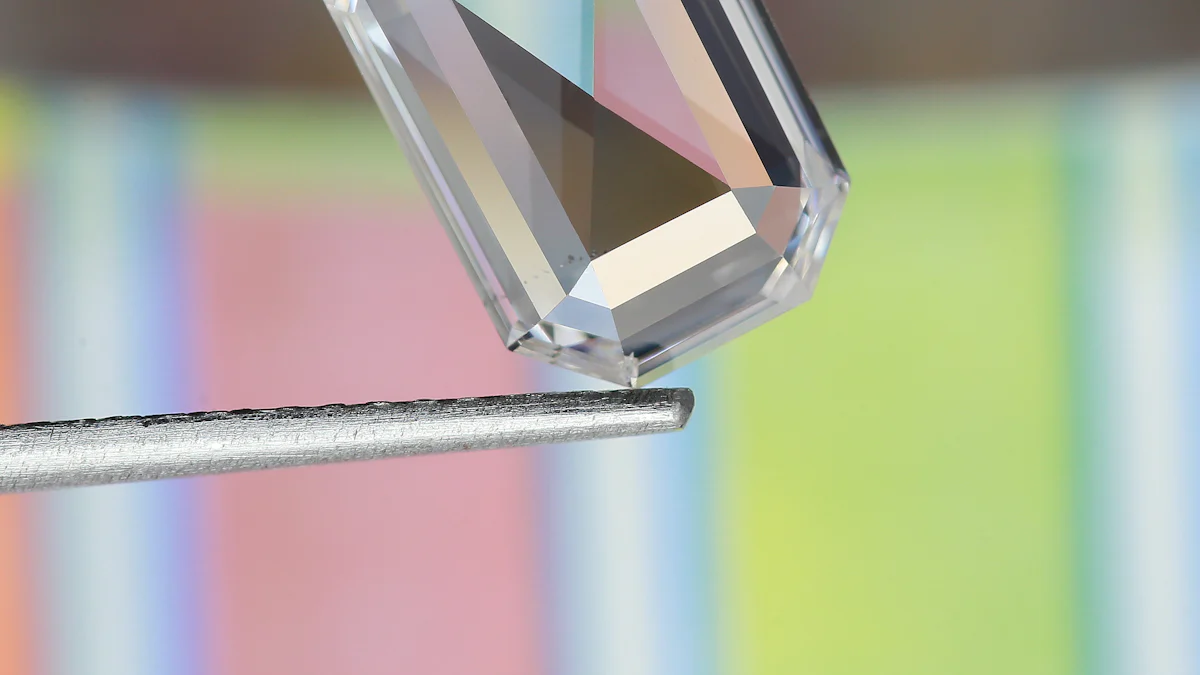

Optical Clarity

High transparency across a wide range of wavelengths

Quartz chambers offer unparalleled optical clarity, transmitting light effectively across ultraviolet (UV), visible, and infrared (IR) spectrums. This feature is crucial for optical and spectroscopic applications, where accurate light transmission directly impacts data quality. For instance, fused silica quartz provides excellent UV transmission, making it ideal for photolithography processes in semiconductor production. The superior transparency of quartz enhances visibility and precision in various scientific tools.

Ideal for optical and spectroscopic applications

The optical properties of quartz chambers make them a preferred choice for spectroscopic instruments and medical devices. Studies comparing quartz and sapphire chambers reveal that quartz delivers better optical performance, including reduced Fresnel reflections and improved visibility. These advantages enable accurate visualization in medical procedures and enhance the reliability of optical measurements in research and industrial applications.

Chemical and Environmental Resistance

Non-reactive with most chemicals

Quartz chambers exhibit remarkable chemical stability, resisting reactions with water, acids, and salt solutions. This non-reactivity ensures their reliability in environments with stringent production requirements, such as semiconductor manufacturing. High-purity quartz materials prevent contamination, maintaining the accuracy and consistency of processes like etching and chemical vapor deposition. Their chemical resistance makes quartz chambers suitable for a wide range of scientific and industrial applications.

Durability in harsh environments

The durability of quartz chambers allows them to withstand harsh environmental conditions, including exposure to corrosive substances and extreme temperatures. Their robust construction ensures long-lasting performance, reducing the need for frequent replacements. Quartz chambers remain reliable in challenging settings, supporting critical operations in fields like metallurgy, new energy, and advanced material research.

Mechanical Strength and Durability

High resistance to wear and tear

Quartz chambers exhibit exceptional mechanical strength, making them highly resistant to wear and tear. This durability stems from the robust molecular structure of quartz, which ensures that the material can withstand repeated use in demanding environments without degrading. For instance, in semiconductor manufacturing processes like chemical vapor deposition (CVD) and etching, quartz chambers endure prolonged exposure to abrasive chemicals and high temperatures. Despite these harsh conditions, they maintain their structural integrity, ensuring consistent performance over time.

The resilience of quartz also makes it an ideal choice for optical and medical applications. Transparent quartz chambers used in optical systems demonstrate superior resistance to scratches and surface damage compared to other materials. This property enhances their longevity and ensures that optical clarity remains uncompromised, even after extended use. By reducing the need for frequent replacements, quartz chambers contribute to cost efficiency and operational reliability in various scientific and industrial settings.

Long-lasting performance in demanding conditions

Quartz chambers deliver long-lasting performance, even under extreme conditions. Their ability to endure high temperatures and resist thermal shocks ensures reliable operation in processes requiring precise temperature control. For example, quartz glass products used in semiconductor applications can withstand extreme heat during photolithography and other thermal processes. This high-temperature resistance minimizes the risk of material failure, supporting uninterrupted production and accurate results.

In addition to thermal stability, quartz chambers excel in maintaining performance in chemically aggressive environments. Their non-reactive nature prevents contamination and degradation when exposed to water, acids, or salt solutions. This chemical stability is particularly valuable in industries with stringent production requirements, such as optoelectronics and advanced material research. The combination of mechanical strength and chemical resistance ensures that quartz chambers remain dependable tools for critical applications.

“Quartz demonstrated lower Fresnel reflections, lower chamber internal temperatures, and shorter cooling times,” highlighting its superior performance in optical and thermal measurements compared to sapphire. This advantage further underscores the long-term reliability of quartz chambers in precision-driven fields.

By offering unmatched durability and resistance to challenging conditions, quartz chambers play a pivotal role in enhancing the efficiency and accuracy of scientific tools. Their robust construction and enduring performance make them indispensable in industries that demand precision and reliability.

Applications of Quartz Chambers in Scientific Instruments

Spectroscopy and Optical Instruments

Enhancing accuracy in spectrometers

Quartz chambers play a critical role in improving the precision of spectrometers. Their exceptional optical clarity ensures accurate light transmission across ultraviolet (UV), visible, and infrared (IR) wavelengths. This capability allows spectrometers to detect even the smallest variations in light intensity, which is essential for applications such as chemical analysis and material characterization. The stability of quartz chambers minimizes external interference, enabling consistent and repeatable measurements. For instance, in advanced spectroscopy techniques, quartz chambers provide the reliability needed to achieve high-resolution results.

Use in laser systems and optical sensors

Laser systems and optical sensors benefit significantly from the properties of quartz chambers. The high transparency of quartz enhances the efficiency of laser beam transmission, reducing energy loss and improving overall system performance. Additionally, quartz chambers resist thermal and mechanical stress, ensuring durability in high-power laser applications. Optical sensors housed in quartz chambers exhibit improved sensitivity and accuracy due to the material’s ability to maintain a stable environment. These advantages make quartz chambers indispensable in fields such as medical imaging, telecommunications, and industrial automation.

Timekeeping and Frequency Standards

Role in quartz oscillators for precise time measurement

Quartz chambers are integral to the operation of quartz oscillators, which serve as the foundation for precise time measurement. The piezoelectric properties of quartz allow it to vibrate at a stable frequency when voltage is applied. This stability ensures that quartz oscillators maintain consistent timing, which is crucial for devices like watches, clocks, and electronic systems. The reliability of quartz chambers enhances the performance of these oscillators, making them a preferred choice for applications requiring high precision.

Applications in atomic clocks and GPS systems

Atomic clocks and GPS systems rely on quartz chambers to achieve unparalleled accuracy. In atomic clocks, quartz oscillators provide the initial frequency standard, which is then fine-tuned using atomic transitions. This combination delivers timekeeping accuracy within billionths of a second. GPS systems depend on this precision to calculate exact positions, ensuring reliable navigation and communication. The durability and stability of quartz chambers make them essential components in these advanced technologies.

Measurement and Analytical Devices

Use in mass spectrometers and chromatographs

Mass spectrometers and chromatographs utilize quartz chambers to enhance measurement accuracy. In mass spectrometry, quartz chambers provide a stable environment for ionization and detection processes, ensuring precise mass-to-charge ratio measurements. Chromatographs benefit from the chemical resistance of quartz, which prevents contamination and maintains the integrity of samples during analysis. These qualities enable researchers to obtain reliable data in fields such as pharmaceuticals, environmental science, and materials research.

Ensuring precision in environmental monitoring tools

Environmental monitoring tools equipped with quartz chambers deliver accurate and consistent results. Quartz chambers resist chemical reactions and environmental degradation, making them suitable for detecting pollutants, measuring air quality, and analyzing water samples. Their ability to maintain stable conditions ensures that these tools provide reliable data, which is critical for addressing environmental challenges and developing sustainable solutions.

Medical and Biological Research Tools

Applications in DNA sequencing and microscopy

Quartz chambers play a pivotal role in advancing DNA sequencing and microscopy technologies. Their exceptional optical clarity ensures precise light transmission, which is critical for visualizing intricate biological structures. In DNA sequencing, quartz chambers provide a stable and non-reactive environment, enabling accurate detection of nucleotide sequences. This stability minimizes errors, ensuring reliable results in genetic research and medical diagnostics.

Microscopy applications also benefit significantly from quartz chambers. The high transparency of quartz enhances the resolution of imaging systems, allowing researchers to observe cellular and molecular details with unparalleled accuracy. Studies comparing quartz and sapphire chambers for medical optical devices revealed that quartz chambers exhibited lower internal temperatures and shorter cooling times. These properties improve the efficiency and reliability of microscopy tools, making them indispensable in biological research.

“Quartz provided better optical and thermal results than sapphire, with lower Fresnel reflections, lower internal temperatures, and shorter cooling times,” as highlighted in comparative studies. This advantage underscores the superiority of quartz in precision-driven applications like microscopy.

Use in diagnostic devices for accurate results

Diagnostic devices rely on quartz chambers to deliver precise and consistent results. The chemical resistance of quartz ensures that it remains non-reactive with biological samples, preserving their integrity during analysis. This property is particularly valuable in devices used for blood testing, tissue analysis, and other diagnostic procedures. Quartz chambers maintain a contamination-free environment, which is essential for obtaining accurate data.

The thermal stability of quartz further enhances the performance of diagnostic devices. For instance, in infrared laser-based medical tools, quartz chambers demonstrated superior vessel sealing performance compared to sapphire. Lower peak temperatures and faster cooling times contribute to more efficient operations, reducing the risk of thermal damage to biological tissues. These attributes make quartz chambers a preferred choice for cutting-edge diagnostic technologies.

By integrating quartz chambers into DNA sequencing, microscopy, and diagnostic devices, researchers and medical professionals achieve higher precision and reliability. The unique properties of quartz continue to drive innovation in medical and biological research tools, supporting advancements in healthcare and life sciences.

Benefits of Quartz Chambers in Scientific Tools

Enhanced Accuracy and Precision

Consistent measurements under varying conditions

Quartz chambers provide unmatched stability, ensuring consistent measurements even in fluctuating environments. Their thermal stability minimizes the impact of temperature changes, which is critical for maintaining precision in scientific tools. For instance, in spectroscopy and optical instruments, quartz chambers enable accurate light transmission across various wavelengths, ensuring reliable data collection. This consistency supports advanced research and industrial processes where precision is non-negotiable.

Reduced errors in data collection

The unique properties of quartz chambers significantly reduce errors during data collection. Their optical clarity ensures accurate visualization, while their chemical resistance prevents contamination. These features make quartz chambers indispensable in applications like DNA sequencing and environmental monitoring. By maintaining a stable and interference-free environment, quartz chambers enhance the reliability of results, reducing the need for repeated experiments and saving valuable time and resources.

Improved Reliability and Longevity

Resistance to wear and environmental degradation

Quartz chambers exhibit exceptional durability, resisting wear and environmental degradation over extended periods. Their robust molecular structure allows them to withstand harsh conditions, including exposure to corrosive substances and extreme temperatures. For example, in semiconductor manufacturing, quartz chambers endure abrasive chemicals and high heat without compromising performance. This resilience ensures that scientific tools equipped with quartz chambers remain operational and reliable, even in demanding settings.

Long-term stability for critical applications

The long-term stability of quartz chambers makes them ideal for critical applications requiring consistent performance. In timekeeping devices like atomic clocks and GPS systems, quartz chambers maintain precise frequency standards over prolonged use. Comparative studies have shown that quartz chambers outperform alternative materials, such as sapphire, by delivering faster cooling times and lower internal temperatures. These advantages contribute to their reliability in fields where accuracy and stability are paramount.

“Quartz demonstrated lower peak temperatures and shorter cooling times compared to sapphire and RF devices,” highlighting its superior performance in precision-driven applications.

Versatility Across Scientific Disciplines

Adaptability to diverse research and industrial needs

Quartz chambers adapt seamlessly to a wide range of scientific and industrial applications. Their chemical resistance and optical clarity make them suitable for fields as varied as medical diagnostics, environmental monitoring, and advanced material research. For instance, in medical devices, quartz chambers provide consistent vessel seals and faster cooling times, ensuring safe and efficient clinical procedures. This adaptability underscores their value across multiple disciplines.

Compatibility with advanced technologies

Quartz chambers integrate effortlessly with cutting-edge technologies, enhancing the capabilities of modern scientific tools. Their compatibility with nanotechnology and photonics enables innovations in quantum computing and semiconductor manufacturing. Additionally, their role in thin-film deposition processes ensures precision in photovoltaic and optoelectronic applications. By supporting advanced technologies, quartz chambers drive progress in both research and industry.

How Quartz Chambers Compare to Other Materials

Advantages Over Glass

Superior thermal and chemical resistance

Quartz chambers surpass glass in thermal and chemical resistance, making them ideal for high-performance applications. Glass often struggles under extreme temperatures, leading to structural instability or deformation. In contrast, quartz maintains its integrity even in environments with rapid temperature fluctuations. For instance, Semicera’s Quartz Chamber demonstrates exceptional stability in semiconductor and optoelectronic manufacturing, where high temperatures are a constant challenge.

Chemical resistance further sets quartz apart. Unlike glass, which can react with certain chemicals over time, quartz remains non-reactive in harsh environments. This property ensures that quartz chambers perform reliably in processes like chemical vapor deposition (CVD) and etching, where exposure to corrosive substances is unavoidable. The durability of quartz under such conditions extends the lifespan of scientific tools, reducing maintenance costs and downtime.

Greater optical clarity and durability

Quartz chambers exhibit superior optical clarity compared to glass, transmitting light effectively across ultraviolet (UV), visible, and infrared (IR) spectrums. This clarity is essential for applications requiring precise light transmission, such as spectroscopy and photolithography. Research comparing quartz and sapphire chambers for IR laser applications revealed that quartz provided better optical results, including lower reflection losses at material-air interfaces. These findings highlight quartz’s ability to enhance the accuracy of optical measurements.

Durability further strengthens quartz’s position over glass. While glass is prone to scratches and surface damage, quartz resists wear and tear even in demanding environments. This resilience ensures that quartz chambers maintain their optical properties over extended use, making them a reliable choice for industries like medical diagnostics and advanced material research.

Advantages Over Metals

Non-reactivity and transparency

Quartz chambers offer a unique combination of non-reactivity and transparency, which metals cannot match. Metals often corrode or react with chemicals, compromising their performance in sensitive applications. Quartz, on the other hand, remains chemically stable, ensuring consistent results in processes like semiconductor manufacturing. Its non-reactive nature also prevents contamination, preserving the purity of samples and materials.

Transparency is another area where quartz outshines metals. While metals block light, quartz allows it to pass through with minimal distortion. This property makes quartz chambers indispensable in optical and spectroscopic instruments, where accurate light transmission is critical. For example, Semicera’s high-quality quartz chambers enhance precision in optoelectronic manufacturing by maintaining stable and reliable conditions under extreme process environments.

Lightweight and corrosion-resistant properties

Quartz chambers combine lightweight construction with exceptional corrosion resistance, offering advantages over metals in various applications. Metals, though strong, are often heavy and susceptible to corrosion when exposed to moisture or chemicals. Quartz eliminates these drawbacks by providing a lightweight yet robust alternative. Its corrosion-resistant properties ensure long-term reliability, even in harsh environments.

The lightweight nature of quartz chambers simplifies their integration into advanced technologies. For instance, in medical and biological research tools, quartz chambers reduce the overall weight of devices without compromising performance. This feature enhances portability and usability, making quartz chambers a preferred choice for cutting-edge scientific instruments.

By delivering unmatched thermal stability, optical clarity, and chemical resistance, quartz chambers outperform both glass and metals in precision-driven applications. Their unique properties continue to drive innovation across diverse scientific and industrial fields.

Innovations in Quartz Chamber Technology

Advances in Manufacturing Techniques

Precision engineering for custom applications

Manufacturers have embraced precision engineering to create quartz chambers tailored for specific scientific and industrial needs. Advanced machining techniques now allow for the production of chambers with intricate geometries and exact dimensions. These custom designs enhance the performance of tools in fields like spectroscopy, semiconductor manufacturing, and medical diagnostics. For instance, precision-engineered quartz chambers used in photolithography ensure uniform light distribution, which is critical for producing high-resolution microchips.

The ability to customize quartz chambers also supports unique research requirements. Scientists working on experimental setups often require chambers with non-standard shapes or features. Precision engineering meets these demands by delivering solutions that maintain the material’s inherent properties, such as thermal stability and chemical resistance. This adaptability has positioned quartz as a cornerstone material for cutting-edge scientific tools.

Integration with nanotechnology

The integration of nanotechnology into quartz chamber manufacturing has unlocked new possibilities for innovation. Nanostructured coatings applied to quartz surfaces improve their functionality by enhancing properties like hydrophobicity, reflectivity, or chemical resistance. These advancements make quartz chambers more effective in applications requiring extreme precision, such as thin-film deposition and quantum computing.

Nanotechnology also enables the creation of ultra-smooth quartz surfaces, reducing imperfections that could interfere with optical or spectroscopic measurements. For example, in vacuum deposition processes, smoother quartz chambers minimize contamination risks and ensure consistent film thickness. This level of precision supports industries like photovoltaics and advanced materials research, where even minor deviations can impact performance.

“Quartz demonstrated lower reflection losses at material-air interfaces (3.3%) compared to sapphire (7.4%),” highlighting its superior optical performance. This advantage becomes even more pronounced when enhanced through nanotechnology, further solidifying quartz’s role in high-precision applications.

Emerging Applications in Cutting-Edge Research

Role in quantum computing and photonics

Quartz chambers have become indispensable in the rapidly evolving fields of quantum computing and photonics. Their exceptional optical clarity and thermal stability make them ideal for housing delicate quantum systems. In quantum computing, quartz chambers provide a controlled environment that minimizes external interference, ensuring stable qubit operations. This stability is crucial for achieving the high levels of precision required in quantum calculations.

Photonics also benefits from the unique properties of quartz. The material’s ability to transmit light across a wide range of wavelengths supports the development of advanced optical devices, such as waveguides and lasers. Quartz chambers used in photonic systems enhance light manipulation, enabling breakthroughs in telecommunications, imaging, and sensing technologies. These innovations are driving progress in industries that rely on ultra-fast data processing and high-resolution imaging.

Use in space exploration and advanced materials research

Space exploration demands materials that can withstand extreme conditions, and quartz chambers have proven to be up to the task. Their resistance to thermal shocks and chemical degradation ensures reliable performance in the harsh environments of outer space. Quartz chambers are used in instruments aboard spacecraft to analyze planetary atmospheres, study cosmic radiation, and conduct experiments in microgravity.

In advanced materials research, quartz chambers play a pivotal role in processes like thin-film deposition and high-temperature synthesis. Their ability to maintain stable conditions under extreme heat supports the development of innovative materials for energy storage, semiconductors, and metallurgy. For example, quartz chambers used in thin-film deposition processes enable precise control over layer thickness, which is essential for creating efficient photovoltaic cells.

Studies have shown that quartz chambers cool down faster than sapphire, with cooling times averaging 13 ± 4 seconds compared to 27 ± 7 seconds. This rapid cooling capability enhances their utility in high-temperature applications, such as space exploration and material synthesis, where efficiency and reliability are paramount.

By combining advanced manufacturing techniques with emerging applications, quartz chambers continue to push the boundaries of what is possible in science and technology. Their versatility and precision make them indispensable in shaping the future of innovation.

Challenges and Limitations of Quartz Chambers

Cost Considerations

Higher initial investment compared to other materials

Quartz chambers often require a higher upfront investment than materials like glass or metals. The production process involves advanced techniques and high-purity quartz, which increases costs. For industries with tight budgets, this initial expense may seem prohibitive. However, the superior properties of quartz, such as its thermal stability and chemical resistance, justify the cost for applications demanding precision.

For example, quartz bangers outperform glass bangers due to their higher melting point and better heat retention. While glass may appear more affordable initially, it is prone to cracking and breaking under stress, leading to frequent replacements. Quartz, on the other hand, offers long-term reliability, reducing overall costs in the long run.

Long-term cost-effectiveness due to durability

The durability of quartz chambers offsets their higher initial cost over time. Their resistance to wear, thermal shocks, and chemical reactions ensures extended operational life. Industries relying on quartz chambers benefit from fewer replacements and lower maintenance expenses. For instance, in optical applications, quartz chambers exhibit lower Fresnel reflections and faster cooling times compared to sapphire. These advantages enhance efficiency and reduce downtime, making quartz a cost-effective choice for precision-driven fields.

“Quartz demonstrated lower chamber internal temperatures and shorter cooling times,” highlighting its ability to maintain performance while minimizing operational disruptions. This durability translates into significant savings for industries requiring consistent and reliable tools.

Manufacturing Complexity

Specialized processes required for production

Producing quartz chambers involves intricate and specialized manufacturing techniques. High-purity quartz must undergo precise cutting, shaping, and polishing to meet the stringent requirements of scientific tools. These processes demand advanced machinery and skilled labor, which contribute to the complexity and cost of production. Unlike materials like glass, quartz requires meticulous handling to preserve its unique properties, such as optical clarity and thermal stability.

Manufacturers also integrate innovative technologies, such as nanostructured coatings, to enhance the functionality of quartz chambers. These coatings improve properties like reflectivity and chemical resistance, further increasing the complexity of production. Despite these challenges, the resulting chambers deliver unmatched performance in applications like spectroscopy and semiconductor manufacturing.

Limited availability of high-quality quartz

The availability of high-quality quartz poses another challenge. Natural quartz deposits suitable for industrial use are limited, and refining raw quartz into high-purity material requires significant resources. This scarcity impacts the supply chain, leading to higher costs and longer lead times for production. Industries relying on quartz chambers must plan carefully to ensure a steady supply of this critical material.

The demand for quartz continues to grow due to its superior performance in precision applications. For example, in advanced material research, quartz chambers outperform alternatives like sapphire by providing better optical and thermal results. However, meeting this demand requires ongoing investment in mining, refining, and manufacturing capabilities.

By addressing these challenges, industries can fully leverage the benefits of quartz chambers. While the initial investment and manufacturing complexity may seem daunting, the long-term advantages of durability, precision, and reliability make quartz an indispensable material for scientific and industrial advancements.

Future Trends in Quartz Chamber Applications

Integration with AI and Automation

Enhancing precision in automated systems

Quartz chambers are becoming integral to the evolution of automated systems. Their unmatched thermal stability and chemical resistance ensure consistent performance, even in high-demand environments. When paired with artificial intelligence (AI), quartz chambers enable automated systems to achieve unprecedented levels of precision. For instance, AI algorithms can monitor and adjust environmental conditions within quartz chambers in real time, ensuring optimal performance for processes like thin-film deposition or spectroscopic analysis.

In manufacturing, quartz chambers enhance the accuracy of robotic systems used in semiconductor production. These chambers provide a stable environment, reducing external interference that could compromise results. AI-driven automation further refines this process by analyzing data from sensors embedded in quartz chambers. This synergy minimizes errors and maximizes efficiency, making quartz chambers indispensable in industries that prioritize precision.

Scientific Research Findings: Studies comparing quartz chambers to sapphire alternatives highlight quartz’s superior cooling times and lower internal temperatures. These attributes make quartz chambers ideal for automated systems requiring rapid adjustments and stable conditions.

Role in smart scientific instruments

Smart scientific instruments rely on quartz chambers to maintain accuracy and reliability. These instruments, equipped with advanced sensors and AI capabilities, benefit from the unique properties of quartz. The material’s optical clarity ensures precise data collection, while its chemical resistance prevents contamination during sensitive experiments.

For example, in medical diagnostics, smart devices use quartz chambers to analyze biological samples with high precision. AI integration allows these devices to process data faster and deliver more accurate results. Quartz chambers also play a critical role in environmental monitoring tools, where smart sensors detect pollutants or measure air quality. The combination of quartz’s stability and AI’s analytical power enhances the functionality of these instruments, driving advancements across multiple scientific disciplines.

Sustainability and Eco-Friendly Innovations

Development of recyclable quartz materials

The push for sustainability has led to innovations in recyclable quartz materials. Manufacturers now explore methods to repurpose quartz chambers at the end of their lifecycle. Advanced recycling techniques recover high-purity quartz from used chambers, reducing waste and conserving natural resources. This approach aligns with global efforts to promote circular economies in industrial production.

Recyclable quartz materials also support industries focused on green technologies. For instance, photovoltaic manufacturing benefits from recycled quartz chambers, which maintain the same level of performance as new ones. By adopting recyclable materials, companies reduce their environmental footprint while maintaining the precision and reliability required for scientific applications.

“Quartz demonstrated lower peak temperatures and shorter cooling times,” as noted in comparative studies. These properties not only enhance performance but also contribute to energy efficiency, further supporting sustainability goals.

Reducing environmental impact in production

Efforts to minimize the environmental impact of quartz chamber production have gained momentum. Manufacturers now implement energy-efficient processes and adopt cleaner technologies to reduce emissions. For example, advancements in nanotechnology allow for the creation of ultra-smooth quartz surfaces with less material waste. These innovations improve production efficiency while maintaining the high standards required for scientific tools.

Additionally, the durability of quartz chambers reduces the need for frequent replacements, lowering the overall demand for raw materials. Industries that use quartz chambers benefit from this longevity, as it aligns with sustainability objectives. By prioritizing eco-friendly practices, manufacturers ensure that quartz chambers remain a cornerstone of precision-driven fields without compromising environmental responsibility.

Key Insight: The long-lasting performance of quartz chambers, combined with their recyclability, positions them as a sustainable choice for industries seeking to balance innovation with environmental stewardship.

Role of Quartz Chambers in Advanced Material Technologies

Applications in Photovoltaics and Semiconductors

Use in thin-film deposition and coating processes

Quartz chambers play a pivotal role in thin-film deposition and coating processes. These processes require precise control over environmental conditions to ensure uniformity and accuracy. Quartz chambers provide the necessary thermal stability and chemical resistance, enabling consistent deposition of thin films on substrates. This precision is critical for industries like photovoltaics, where even minor deviations in film thickness can impact the efficiency of solar cells.

The optical clarity of quartz enhances its effectiveness in these applications. It allows for accurate monitoring of deposition processes, ensuring that each layer meets the required specifications. For example, quartz chambers used in vacuum deposition systems maintain stable internal temperatures and resist contamination, which ensures high-quality coatings. These attributes make quartz chambers indispensable in producing advanced materials for energy and electronics.

“Quartz demonstrated lower chamber internal temperatures and shorter cooling times,” highlighting its superior performance in maintaining process efficiency compared to sapphire and other materials.

Ensuring precision in semiconductor manufacturing

Semiconductor manufacturing demands unparalleled precision, and quartz chambers meet this requirement with their unique properties. Their low thermal expansion ensures dimensional stability during high-temperature processes like photolithography and chemical vapor deposition (CVD). This stability prevents distortions, allowing manufacturers to produce microchips with intricate patterns and high accuracy.

Quartz chambers also resist chemical reactions, which is essential for maintaining the purity of semiconductor materials. Their non-reactive nature minimizes contamination risks, ensuring consistent results in etching and doping processes. Additionally, the durability of quartz chambers reduces downtime caused by wear and tear, enhancing productivity in semiconductor fabrication facilities. These qualities position quartz as a cornerstone material in the advancement of semiconductor technologies.

Contributions to New Energy and Metallurgy

Enhancing efficiency in energy storage systems

Quartz chambers contribute significantly to the development of energy storage systems. Their ability to withstand extreme temperatures and resist chemical degradation makes them ideal for processes like battery electrode fabrication and electrolyte testing. These processes require stable environments to achieve optimal performance and longevity in energy storage devices.

In lithium-ion battery production, quartz chambers ensure precise control over material synthesis, which directly impacts battery efficiency and capacity. Their thermal stability supports high-temperature reactions, while their chemical resistance prevents contamination of sensitive components. By enabling consistent and reliable production, quartz chambers drive innovation in energy storage technologies, supporting the global shift toward renewable energy solutions.

Role in high-temperature and corrosive environments

The robustness of quartz chambers allows them to excel in high-temperature and corrosive environments, which are common in metallurgy and advanced material research. Their resistance to thermal shocks ensures reliable performance during processes like metal smelting and alloy production. Quartz chambers maintain structural integrity even under extreme heat, reducing the risk of material failure.

In corrosive environments, quartz chambers outperform alternative materials by resisting reactions with aggressive chemicals. This durability extends their lifespan and ensures consistent results in applications like chemical vapor deposition and plasma etching. For instance, quartz chambers used in metallurgical research provide stable conditions for studying material properties, enabling breakthroughs in high-performance alloys and coatings.

Studies have shown that quartz chambers cool down faster than sapphire, with cooling times averaging 13 ± 4 seconds compared to 27 ± 7 seconds. This rapid cooling capability enhances their utility in high-temperature applications, improving efficiency and reliability in demanding industrial processes.

By supporting advancements in photovoltaics, semiconductors, energy storage, and metallurgy, quartz chambers continue to drive progress in advanced material technologies. Their unmatched precision, durability, and versatility make them indispensable in shaping the future of science and industry.

Quartz chambers have revolutionized the precision and reliability of scientific tools. Their unmatched thermal stability, optical clarity, and chemical resistance make them indispensable across diverse fields, from spectroscopy to advanced material research. These chambers not only enhance accuracy but also ensure long-term durability, reducing operational disruptions. As industries continue to innovate, quartz chambers will remain at the forefront, driving advancements in technology and scientific exploration. Their role as a cornerstone material underscores their value in shaping the future of precision-driven applications.

FAQ

What makes quartz chambers superior to other materials in scientific tools?

Quartz chambers excel due to their unique properties, including exceptional thermal stability, optical clarity, and chemical resistance. These qualities ensure precise measurements and long-term reliability. For instance, scientific research comparing quartz and sapphire chambers found that quartz demonstrated lower Fresnel reflections, shorter cooling times, and better thermal performance, making it the preferred choice for precision-driven applications.

How do quartz chambers enhance accuracy in spectroscopy?

Quartz chambers improve spectroscopy accuracy by transmitting light effectively across ultraviolet (UV), visible, and infrared (IR) wavelengths. Their high optical clarity minimizes distortion, ensuring reliable data collection. This feature is critical for detecting subtle variations in light intensity during chemical analysis or material characterization.

Why are quartz chambers essential in semiconductor manufacturing?

Quartz chambers play a vital role in semiconductor manufacturing due to their thermal stability and chemical resistance. They maintain dimensional integrity during high-temperature processes like photolithography and chemical vapor deposition (CVD). Additionally, their non-reactive nature prevents contamination, ensuring the purity of semiconductor materials.

Can quartz chambers withstand extreme environmental conditions?

Yes, quartz chambers exhibit remarkable durability in harsh environments. They resist thermal shocks, corrosive substances, and mechanical wear, making them suitable for demanding applications. For example, in metallurgy and advanced material research, quartz chambers maintain structural integrity under extreme heat and chemical exposure.

How do quartz chambers contribute to advancements in solar power technology?

Quartz chambers are indispensable in the solar power industry. They enable precise thin-film deposition processes, which are essential for producing efficient photovoltaic cells. According to Solar Power World Online, fused quartz improves solar device efficiency and reduces production costs, supporting the growth of renewable energy solutions.

What role do quartz chambers play in medical diagnostics?

Quartz chambers enhance medical diagnostic tools by providing stable, non-reactive environments for biological sample analysis. Their optical clarity ensures accurate visualization, while their chemical resistance prevents contamination. These properties make quartz chambers ideal for DNA sequencing, blood testing, and tissue analysis.

Are quartz chambers cost-effective despite their higher initial investment?

Quartz chambers offer long-term cost-effectiveness due to their durability and reliability. While they require a higher initial investment, their resistance to wear and environmental degradation reduces maintenance and replacement costs. For example, studies comparing quartz and sapphire chambers highlighted quartz’s faster cooling times and lower internal temperatures, which enhance operational efficiency.

How do quartz chambers support quantum computing and photonics?

Quartz chambers provide controlled environments essential for quantum computing and photonics. Their optical clarity and thermal stability ensure precise light manipulation and stable qubit operations. These features drive advancements in telecommunications, imaging, and sensing technologies.

What innovations have improved quartz chamber technology?

Recent innovations include precision engineering and nanotechnology integration. Manufacturers now produce custom-designed quartz chambers with enhanced properties like hydrophobicity and reflectivity. These advancements improve performance in applications such as thin-film deposition and quantum computing.

Are quartz chambers environmentally sustainable?

Quartz chambers align with sustainability goals through their recyclability and long lifespan. Manufacturers have developed methods to repurpose used quartz, reducing waste and conserving resources. Additionally, their durability minimizes the need for frequent replacements, lowering the environmental impact of production.