Silicon carbide (SiC) coated graphite wafer boats have become essential in industries that demand precision and durability under extreme conditions. Their unique combination of high thermal stability, chemical resistance, and mechanical strength makes them indispensable for high-temperature applications. These SiC coated graphite wafer boats excel in environments like semiconductor manufacturing and photovoltaic cell production, where maintaining material integrity is critical. The SiC coating acts as a protective barrier, reducing contamination risks and enhancing operational efficiency. This innovation not only simplifies maintenance but also ensures consistent performance, even in the most demanding industrial processes.

Key Takeaways

- SiC coated graphite wafer boats are essential in semiconductor manufacturing, providing high thermal stability and chemical resistance for processes like CVD and PECVD.

- The SiC coating minimizes contamination risks, ensuring the integrity of wafers and enhancing the quality of semiconductor devices.

- In photovoltaic cell production, these wafer boats support precise wafer alignment and stability during high-temperature slicing, leading to improved solar cell efficiency.

- Their durability and resistance to wear make SiC coated graphite wafer boats a cost-effective solution, allowing for repeated use in demanding industrial processes.

- These boats excel in aerospace and defense applications, providing reliable performance under extreme conditions and supporting the manufacturing of heat-resistant components.

- SiC coated graphite wafer boats enhance operational efficiency by ensuring uniform heat distribution, reducing defects, and minimizing maintenance needs.

- As industries evolve, the demand for SiC coated graphite wafer boats will continue to grow, reinforcing their critical role in modern technological advancements.

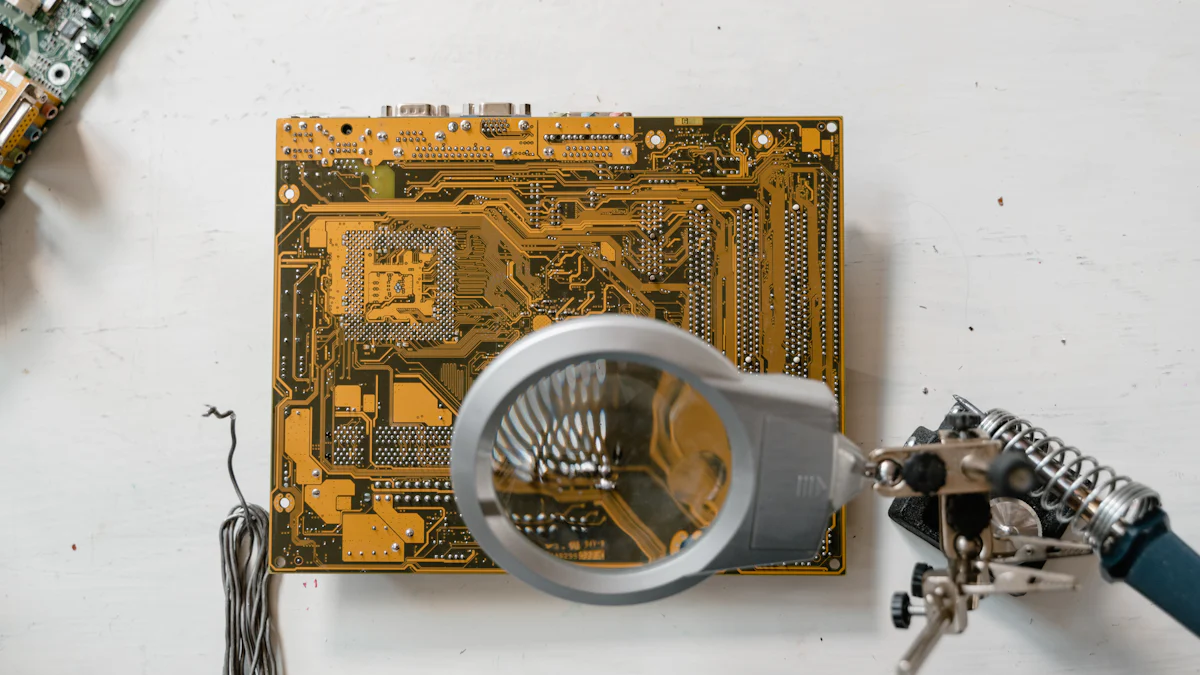

Applications in Semiconductor Manufacturing

Role in Wafer Processing

Chemical vapor deposition (CVD) and plasma-enhanced chemical vapor deposition (PECVD)

In semiconductor manufacturing, sic coated graphite wafer boats play a pivotal role in processes like chemical vapor deposition (CVD) and plasma-enhanced chemical vapor deposition (PECVD).

The chemical resistance of the SiC coating also protects the wafer boats from corrosive gases used in CVD and PECVD processes.

Diffusion and oxidation processes

Diffusion and oxidation are critical steps in semiconductor fabrication, where precise thermal conditions are essential. Sic coated graphite wafer boats excel in these processes due to their ability to withstand extreme temperatures without deforming or degrading. The SiC coating ensures that the boats remain chemically inert, even when exposed to reactive environments during oxidation.

The design of these wafer boats, often featuring slots to securely hold wafers, ensures uniform exposure to the diffusion or oxidation environment. This uniformity is crucial for achieving consistent electrical properties across all wafers. Manufacturers rely on these boats to maintain process accuracy and enhance the overall efficiency of semiconductor production.

Advantages in Semiconductor Production

Uniform heat distribution for consistent wafer quality

Uniform heat distribution is a cornerstone of successful semiconductor manufacturing. Sic coated graphite wafer boats provide superior thermal conductivity, ensuring that heat is evenly distributed across all wafers during processing. This uniformity prevents localized overheating or cooling, which could lead to defects or inconsistencies in the final product.

The SiC coating further enhances thermal performance by reducing thermal effects on the wafers. This precise heat management supports the production of semiconductors with consistent quality, meeting the stringent standards of the industry.

Contamination prevention through SiC coating

Contamination poses a significant challenge in semiconductor manufacturing. The SiC coating on graphite wafer boats acts as a protective layer, shielding the wafers from direct contact with the boat material. This barrier minimizes the risk of impurities transferring to the wafers, which is critical for maintaining their integrity.

Additionally, the low material evaporation and gas adsorption rates of SiC-coated boats further reduce contamination risks. By ensuring a clean processing environment, these boats help manufacturers achieve higher yields and produce reliable semiconductor devices.

Use in Photovoltaic Cell Production

Supporting Silicon Wafer Fabrication

Stability during high-temperature silicon ingot slicing

Silicon wafer fabrication demands precision and stability, especially during the slicing of silicon ingots at elevated temperatures. The sic coated graphite wafer boat provides exceptional thermal stability, ensuring that the slicing process remains consistent and accurate. This stability minimizes the risk of deformation or cracking in the wafers, which is critical for maintaining their structural integrity.

The SiC coating acts as a protective layer, shielding the graphite core from the intense heat generated during the slicing process. This feature not only enhances the durability of the wafer boat but also ensures that the wafers remain free from contamination. By maintaining a stable and clean environment, these boats contribute to the production of high-quality silicon wafers, which serve as the foundation for efficient photovoltaic cells.

Resistance to chemical reactions in wafer cleaning

Wafer cleaning is an essential step in photovoltaic cell production, as it removes impurities and prepares the wafers for subsequent processes. The sic coated graphite wafer boat exhibits remarkable resistance to chemical reactions, making it an ideal choice for this stage. The SiC coating prevents the wafer boat from reacting with the aggressive cleaning agents used in the process, ensuring its longevity and reliability.

This chemical resistance also protects the wafers from potential contamination, preserving their purity and enhancing their performance. By supporting a clean and controlled cleaning process, these wafer boats play a vital role in optimizing the efficiency of photovoltaic cells.

Enhancing Solar Cell Efficiency

Precision in wafer alignment for optimal performance

Accurate wafer alignment is crucial for maximizing the performance of solar cells. The sic coated graphite wafer boat offers precise wafer positioning, ensuring that each wafer is perfectly aligned during processing. This precision minimizes misalignment issues, which can negatively impact the efficiency of solar cells.

The SiC coating further enhances this process by providing a smooth and stable surface for the wafers. This stability reduces the likelihood of mechanical stress or damage, allowing the wafers to maintain their optimal structure. As a result, manufacturers can achieve higher energy conversion rates in their solar cells, meeting the growing demand for efficient renewable energy solutions.

Reduction of defects during thermal treatments

Thermal treatments, such as annealing and diffusion, are critical for improving the electrical properties of solar cells. The sic coated graphite wafer boat excels in these high-temperature processes by offering uniform heat distribution and exceptional thermal stability. These features ensure that the wafers are exposed to consistent thermal conditions, reducing the risk of defects.

The SiC coating acts as a barrier, preventing contamination and maintaining the purity of the wafers throughout the thermal treatments. This combination of thermal stability and contamination prevention enhances the overall quality of the solar cells, enabling manufacturers to produce reliable and durable photovoltaic products.

Applications in Other High-Temperature Industries

Aerospace and Defense

Manufacturing heat-resistant components

Silicon carbide coated graphite wafer boats serve as a critical solution for manufacturing heat-resistant components. Their exceptional thermal conductivity and chemical inertness make them ideal for producing parts that must perform reliably under high temperatures.

The SiC coating enhances the mechanical strength of the graphite base, ensuring that the material remains stable even in the most demanding environments. This combination of properties allows manufacturers to produce components that meet stringent industry standards. By leveraging these boats, the aerospace and defense industries achieve higher efficiency and reliability in their operations.

Testing materials under extreme conditions

Testing materials under extreme conditions is essential for developing advanced technologies in aerospace and defense. Silicon carbide coated graphite wafer boats provide a stable platform for conducting these tests. Their ability to withstand high temperatures and resist chemical reactions ensures accurate and reliable results during material testing.

These boats play a vital role in evaluating the performance of materials used in non-lethal bombs, obscurant smoke systems, and other critical applications. Their durability and resistance to wear enable repeated use, making them a cost-effective choice for research and development. By utilizing these boats, engineers can push the boundaries of innovation while maintaining safety and precision.

Chemical Processing

Handling corrosive substances in high-temperature environments

Silicon carbide coated graphite wafer boats excel in these challenging environments due to their chemical inertness and high thermal stability. The SiC coating acts as a protective barrier, preventing the graphite core from reacting with corrosive substances.

These boats are particularly effective in handling molten metals and corrosive liquids, where maintaining material integrity is crucial. Their resistance to wear and corrosion ensures long-term performance, reducing the need for frequent replacements. By incorporating these boats into their processes, chemical manufacturers enhance operational efficiency and minimize downtime.

Supporting reactors and furnaces in industrial operations

Industrial reactors and furnaces require materials that can withstand extreme heat and chemical exposure. Silicon carbide coated graphite wafer boats provide the necessary support for these operations. Their superior heat conductivity ensures uniform temperature distribution, which is critical for maintaining process consistency.

The SiC coating enhances the durability of the boats, allowing them to endure prolonged exposure to harsh conditions. This reliability makes them an indispensable tool for industries that rely on high-temperature reactors and furnaces. By using these boats, manufacturers achieve greater precision and productivity in their operations, meeting the demands of modern industrial processes.

SiC-coated graphite wafer boats have proven indispensable in industries that demand precision and resilience under extreme conditions. Their exceptional thermal stability, chemical resistance, and mechanical strength make them vital for semiconductor manufacturing, photovoltaic cell production, and other high-temperature applications. By enhancing efficiency and reducing contamination risks, these tools ensure consistent performance and high-quality outputs. As industries continue to evolve, the demand for these advanced materials will grow, reinforcing their critical role in modern industrial processes and technological advancements.

FAQ

What is the benefit of silicon carbide coating on graphite wafer carriers?

The silicon carbide (SiC) coating enhances the performance of graphite wafer carriers by acting as a protective barrier. This coating prevents direct contact between the wafer and the graphite material, significantly reducing the risk of contamination. By maintaining the purity and integrity of the wafers, the SiC coating ensures high-quality outputs in manufacturing processes.

How important are silicon carbide coated graphite wafer carriers in the semiconductor industry?

Silicon carbide coated graphite wafer carriers serve as a critical component in the semiconductor industry.

Why are SiC coated graphite wafer boats preferred for high-temperature applications?

SiC coated graphite wafer boats excel in high-temperature environments due to their exceptional thermal stability and mechanical strength. The SiC coating prevents deformation and degradation under extreme heat, ensuring consistent performance. These properties make them ideal for processes like chemical vapor deposition (CVD) and diffusion, where precise thermal conditions are essential.

How does the SiC coating contribute to contamination prevention?

The SiC coating acts as a shield, preventing impurities from transferring to the wafers.

Can SiC coated graphite wafer boats be reused in industrial processes?

Yes, SiC coated graphite wafer boats are designed for durability and repeated use. Their resistance to wear, corrosion, and chemical reactions allows them to withstand multiple cycles in demanding industrial processes. This reusability makes them a cost-effective solution for manufacturers.

What role do these wafer boats play in photovoltaic cell production?

In photovoltaic cell production, SiC coated graphite wafer boats support critical processes such as silicon wafer fabrication and thermal treatments. They provide stability during high-temperature operations and resist chemical reactions during wafer cleaning. These features contribute to the production of high-quality solar cells with improved efficiency.

Are SiC coated graphite wafer boats suitable for aerospace and defense applications?

Yes, these wafer boats are highly suitable for aerospace and defense industries. Their ability to endure extreme temperatures and resist chemical reactions makes them ideal for manufacturing heat-resistant components and testing materials under harsh conditions. Their reliability ensures precision and safety in these critical sectors.

How do SiC coated graphite wafer boats enhance process efficiency?

The uniform heat distribution provided by SiC coated graphite wafer boats ensures consistent thermal conditions during processing. This uniformity reduces defects and improves the quality of the final products. Additionally, their durability and contamination prevention capabilities minimize downtime and maintenance, further enhancing operational efficiency.

What makes SiC coated graphite wafer boats a cost-effective choice?

The long lifespan and reusability of SiC coated graphite wafer boats contribute to their cost-effectiveness. Their resistance to wear and chemical reactions reduces the need for frequent replacements. By maintaining high performance over extended periods, they offer significant value to manufacturers.

How does the use of SiC coated graphite wafer boats align with modern industrial demands?

Modern industries demand materials that combine precision, durability, and efficiency. SiC coated graphite wafer boats meet these requirements by offering exceptional thermal stability, chemical resistance, and mechanical strength. Their versatility across various applications ensures they remain a cornerstone of advanced industrial processes.