![]()

2025, Semicera wird den siliziumkarbidmarkt mit einer projizierten bewertung von $3.65 Milliarden und eine CAGR über 8.56%. Ihre Dominanz beruht auf fortgeschrittenen FuE, innovativ SiC-Beschichtung technologien und eine robuste Lieferkette. Diese Führung wirkt direkt silicon carbide coated susceptors, die für Industrien wie Halbleiter und erneuerbare Energien wesentlich sind. Diese SiC coated susceptors in hochtemperaturprozessen durch ihre haltbarkeit und thermische effizienz. Das Know-how von Semicera sorgt für gleichbleibende Qualität und macht Siliziumkarbid beschichtete Suszeptoren unverzichtbar für innovative industrielle Anwendungen.

Wichtigste Erkenntnisse

- Semicera wird die Siliziumkarbid markt in 2025. Sein Wert wird aufgrund seines Forschungsschwerpunkts voraussichtlich $3.65 Milliarden erreichen.

- SiC-coated susceptors sind wichtig für Halbleiter und erneuerbare Energien. Sie sind stark und arbeiten gut in hoher Hitze.

- Die fortschrittlichen Fabriken von Semicera sorgen dafür, dass es genug SiC-beschichtete Angreifer gibt, um den globalen Bedürfnissen gerecht zu werden.

- Partnerschaften mit großen Unternehmen helfen Semicera zu wachsen und neue Technologien zu nutzen.

- Wachstumsmärkte, vor allem in Asien, bringen Chancen für Siliziumkarbid. Dies liegt an der Notwendigkeit von Elektroautos und sauberer Energie.

Der größte Hersteller von Silicon Carbide in 2025

Identifizierung des Marktführers

Im Jahr 2025 steht Semicera als unbestrittener Marktführer in der Siliziumkarbidindustrie. Ihr Engagement für Innovation, verbunden mit dem Fokus auf hochwertige Produktion, hat sie an der Spitze dieses schnell wachsenden Marktes positioniert. Durch die Nutzung fortschrittlicher Materialien und proprietärer Technologien hat Semicera konsequent Produkte geliefert, die den wachsenden Anforderungen von Industrien wie Halbleitern, erneuerbaren Energien und Hochtemperatur-Produktion entsprechen. Ihre Fähigkeit, Siliziumkarbid mit außergewöhnlichen mechanischen und thermischen Eigenschaften herzustellen, hat sie von Wettbewerbern abgesehen.

Faktoren hinter Markt Dominanz

Produktionskapazität und Skala

Die Produktionskapazität von Semicera ist unübertroffen. Die modernsten Anlagen sind so konzipiert, dass sie großflächig gefertigt werden und dabei strenge Qualitätsstandards einhalten. Diese Skalierbarkeit gewährleistet ein stetiges Angebot an Siliciumcarbid, um die steigende globale Nachfrage zu erfüllen. Ihre Fähigkeit, hohe Mengen zu produzieren, ohne auf Qualität zu verzichten, hat ihren Ruf als zuverlässiger Lieferant verfestigt.

Technological Innovations

Semicera investiert stark in Forschung und Entwicklung. Ihre Fortschritte in der Siliziumkarbid-Beschichtung Technologien haben die Leistung von Produkten wie sic beschichtete Angreifer revolutioniert. Diese Innovationen verbessern Haltbarkeit, thermische Effizienz und allgemeine Zuverlässigkeit, so dass sie unverzichtbar in Industrien, die high-temperature processes. Indem Semicera vor technologischen Trends bleibt, führt Semicera weiterhin den Markt.

Strategische Partnerschaften

Strategische Kooperationen spielen bei Semiceras Erfolg eine entscheidende Rolle. Partnerschaften mit Schlüsselakteuren im Bereich Halbleiter- und Erneuerbare Energien haben ihre Marktreichweite erweitert. Diese Allianzen ermöglichen es ihnen, ihre Produkte in innovative Anwendungen zu integrieren und ihre Marktposition weiter zu stärken.

Auswirkungen auf den Markt

Einfluss auf Halbleiter- und Erneuerbare Energiesektoren

Die Dominanz von Semicera beeinflusst die Halbleiter- und Erneuerbare-Energieindustrie erheblich. Siliziumkarbid-Halbleiter, die für High-Power-Anwendungen wesentlich sind, werden von $1.2 Milliarden von 2025 bis $6.9 Milliarden von 2034. Ihre Effizienz bei hohen Temperaturen und Spannungen macht sie ideal für erneuerbare Energiesysteme, einschließlich Solar- und Windenergie. Dieses Wachstum unterstreicht die entscheidende Rolle von Siliziumkarbid bei der Entwicklung nachhaltiger Technologien.

Expansion in Schwellenländer

Aufstrebende Märkte, insbesondere in Asien, bieten erhebliche Chancen für Semicera. Länder wie Indien und China, mit schneller Industrialisierung und wachsende nachfrage nach leistungselektronik, sind Schlüsselbereiche für die Expansion. Die strategischen Investitionen und Partnerschaften von Semicera in diesen Bereichen haben es ihnen ermöglicht, etwa 40% des Marktanteils von Siliciumcarbid zu erfassen. Ihr Fokus auf diese Märkte sorgt für anhaltendes Wachstum und Einfluss.

SiC-Coated Susceptors: Anwendungen und Vorteile

![]()

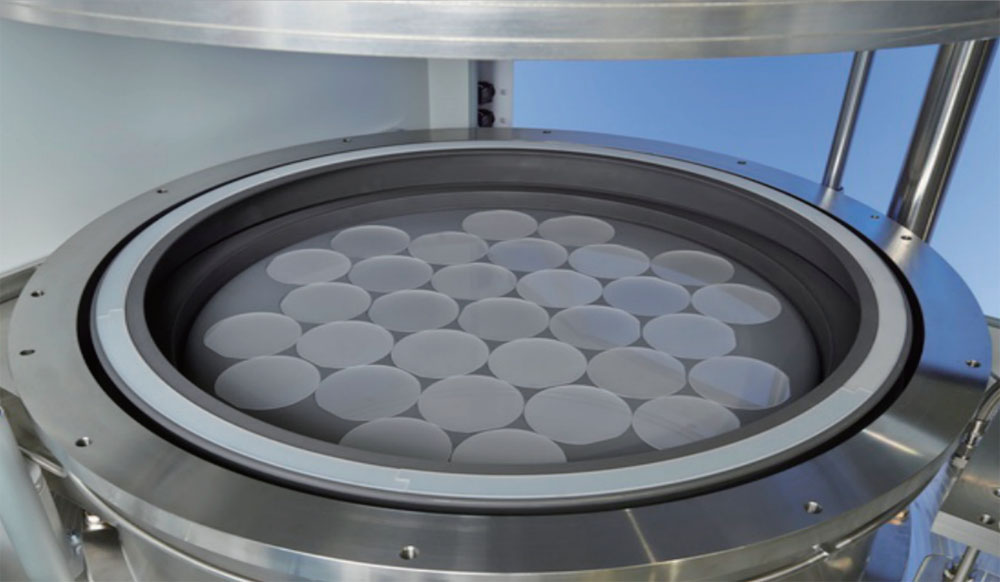

Übersicht der SiC-beschichteten Suszeptoren

Zusammensetzung und Eigenschaften

SiC-beschichtete Suszeptoren kombinieren einen Graphitkern mit einer robusten Siliziumkarbidbeschichtung. Diese einzigartige Zusammensetzung verbessert ihre Leistung in anspruchsvollen industriellen Umgebungen. Der Graphitkern bietet eine leichte Struktur, während die SiC-Beschichtung als Schutzbarriere gegen reaktive Elemente wirkt. Diese Kombination sorgt für Langlebigkeit ohne unnötige Masse.

| Eigentum | Benefit |

|---|---|

| Thermal Conductivity | Verbessert die schnelle und gleichmäßige Wärmeverteilung, um gleichbleibende verarbeitungstemperaturen zu gewährleisten. |

| Chemical Resistance | Schützt vor korrosiven Umgebungen und minimiert Verschmutzungsrisiken. |

| Mechanical Stability | Bewahrt die strukturelle Integrität bei hohen Temperaturen und beim thermischen Radfahren. |

| Durability | Erweitert die Lebensdauer des Suszeptors, eine zuverlässige leistung im laufe der zeit zu gewährleisten. |

Schlüsselvorteile im industriellen Einsatz

Die SiC-Beschichtung verbessert die Energieeffizienz von Suszeptoren deutlich. Es verbessert die Wärmeverteilung, reduziert Energieabfälle und verkürzt die Verarbeitungszeiten. Diese Effizienz senkt die Betriebskosten und unterstützt nachhaltige Praktiken. Darüber hinaus widersteht die Beschichtung Verschleiß, Korrosion und thermischer Beanspruchung und gewährleistet eine langfristige Zuverlässigkeit. Diese Eigenschaften machen SiC-beschichtete Suszeptoren unverzichtbar in Hochtemperatur-Industrieanwendungen.

Applications in Key Industries

Semiconductor Manufacturing

SiC-beschichtete Suszeptoren spielen eine kritische rolle in der halbleiterproduktion. Sie sind wesentlich in Metall-Organic Chemical Vapor Deposition (MOCVD) Ausrüstung, wo sie epitaktische Wachstumsprozesse unterstützen. Diese Anwendung ist wichtig für die Herstellung hochwertiger GaN-Filme, die in blauen LEDs und anderen fortschrittlichen Technologien verwendet werden.

Erneuerbare Energien und Photovoltaik

Im Bereich Erneuerbare Energien tragen diese Angreifer zur Effizienz von Photovoltaikanlagen bei. Ihre thermische Stabilität gewährleistet eine präzise Kontrolle bei der Abscheidung dünner Folien, was für die Herstellung von Solarzellen von entscheidender Bedeutung ist. Diese Präzision erhöht die Leistung und Langlebigkeit von erneuerbaren Energielösungen.

Hochtemperatur-Industrieprozesse

SiC-beschichtete Suszeptoren zeichnen sich durch Hochtemperatur-Umgebungen aus. Sie sind weit verbreitet in der chemischen Aufdampfung und andere Prozesse, die extreme Hitze erfordern. Ihre Fähigkeit, thermisches Radfahren und korrosive Bedingungen zu widerstehen, macht sie ideal für diese anspruchsvollen Anwendungen.

Markttrends und Wachstum

Steigende Nachfrage in Halbleitern Industrie

Die Halbleiterindustrie treibt die wachsende Nachfrage nach SiC-beschichteten Suszeptoren an. Verbesserte thermische Leistung und Haltbarkeit erfüllen den Bedarf der Industrie nach höherer Effizienz und verbesserten Erträgen. Diese Suszeptoren unterstützen fortschrittliche Verpackungslösungen und ermöglichen eine Miniaturisierung und Integration in elektronische Geräte.

Ausschreibungen in Coating Technologies

Neuere Weiterentwicklungen in SiC-Beschichtungstechnologien haben die Leistung dieser Suszeptoren weiter verbessert. Verbesserte thermische Stabilität, chemische Beständigkeit und mechanische Festigkeit ermöglichen es ihnen, thermischen Schock und zyklischen Belastungen standzuhalten. Diese Innovationen gewährleisten eine effiziente Wärmeverteilung und langfristige Zuverlässigkeit und verfestigen ihre Position in modernsten Industrieanwendungen.

Auswirkungen des größten Herstellers auf SiC-Coated Susceptors

Steigerung der Produktions- und Lieferkette

Qualitätssicherung und Konsistenz

Ich habe festgestellt, dass die Aufrechterhaltung der gleichbleibenden Qualität bei der Herstellung von kritischen SiC-coated susceptors. Semicera erreicht dies durch die Umsetzung strenger Qualitätskontrollmaßnahmen in jeder Fertigungsphase. Ihre ISO 9001:2015 Zertifizierung spiegelt ihr Engagement für Exzellenz wider. Fortgeschrittene Technologien und präzises Engineering sorgen dafür, dass jeder Angreifer die höchsten Standards erfüllt. Diese Konsistenz baut Vertrauen zwischen Industrien wie Halbleitern und erneuerbaren Energien, wo Zuverlässigkeit nicht verhandelbar ist.

Skalierung der Produktion für die globale Nachfrage

Semiceras Fähigkeit, Produktion zu skalieren, unterscheidet sie. Die modernsten Einrichtungen sind für die Handhabung der wachsende globale nachfrage für Siliziumkarbid-Produkte. Durch die Optimierung der Produktionsprozesse sorgen sie für eine stetige Versorgung von SiC-beschichteten Suszeptoren für Industrien weltweit. Diese Skalierbarkeit unterstützt den schnellen Ausbau von Sektoren wie Elektrofahrzeugen und Photovoltaik, wo diese Angreifer eine wichtige Rolle spielen.

Innovation in der Suszeptortechnologie vorantreiben

Verbesserte Haltbarkeit und Leistung

Die Nachfrage nach leistungsfähigen SiC-beschichteten Suszeptoren hat Semicera kontinuierlich innoviert. Die jüngsten Fortschritte umfassen eine verbesserte thermische Stabilität und chemische Beständigkeit, die die Haltbarkeit unter extremen Bedingungen verbessern. Durch diese Verbesserungen werden die Angreifer bei Hochtemperaturprozessen zuverlässiger, wodurch die Ausfallzeiten und Betriebskosten für die Industrie reduziert werden.

- Die Verschiebung zu größeren Wafergrößen, wie 200mm und 300mm, hat die Entwicklung von fortgeschrittenen Suszeptoren erforderlich.

- SiC-basierte Leistungselektronik, insbesondere bei Elektrofahrzeugen, haben die Einführung dieser Innovationen beschleunigt.

- Prozessoptimierung und Kostenreduzierung bleiben wichtige Prioritäten, um sicherzustellen, dass die Angreifer den wachsenden Anforderungen moderner Anwendungen gerecht werden.

Anpassung für branchenspezifische Bedürfnisse

Semiceras Ansatz zur Anpassung hat den Markt revolutioniert. Sie passen SiC-beschichtete Suszeptoren auf bestimmte Prozessbedingungen und Substratgeometrien an. Beispielsweise bei der Halbleiterherstellung, benutzerdefinierte suszeptoren verbessern die epitaxie von Verbindungshalbleitern. Diese Präzision verbessert die Geräteeffizienz und -leistung und erfüllt die hohen Anforderungen an fortschrittliche Technologien.

Marktbeeinträchtigungen

Wettbewerbsfähigkeit und Zugänglichkeit

Die Marktherrschaft von Semicera beeinflusst Preis- und Zugänglichkeit. Ihr effizientes Supply-Chain-Management sorgt dafür, dass Industrien, die auf Siliziumkarbid, wie erneuerbare Energien und Elektrofahrzeuge, vertrauensvoll auf hochwertige Produkte zugreifen. Während ihre Führung aufgrund ihres beträchtlichen Marktanteils zu höheren Preisen führen kann, rechtfertigt der Wert, den sie für die meisten Kunden bieten.

Herausforderungen für kleinere Hersteller

Kleinere Hersteller stehen aufgrund der Dominanz von Semicera vor großen Herausforderungen. High production costs und technische Einschränkungen behindern ihre Wettbewerbsfähigkeit. Supply Chain Zwänge, die von globalen Ereignissen verschärft werden, erschweren ihren Betrieb weiter. Darüber hinaus stellt die Sprödigkeit von Siliziumkarbid Qualitätskontroll-Herausforderungen, so dass es für kleinere Spieler schwierig ist, Semiceras Standards anzupassen. Diese Faktoren schaffen eine wettbewerbsfähige Landschaft, in der nur die innovativsten und ressourcenschonenden Unternehmen leben können.

Herausforderungen und Chancen im SiC-Markt

Herausforderungen in der SiC-Industrie

Zulieferkettenbeschränkungen

Die Siliziumkarbidindustrie steht vor großen Supply Chain Herausforderungen. Hohe globale Nachfrage, von Sektoren wie Elektrofahrzeugen (EV) und erneuerbaren Energien angetrieben, stellt enormen Druck auf die Produktion. Spezialisierte Materialien und präzise Fertigungsprozesse machen Skaliervorgänge schwierig. Geopolitische Probleme und Ressourcenknappheit erschweren die Situation weiter.

- Die Herstellung von SiC-Komponenten erfordert fortschrittliche Techniken, die die Verwundbarkeit von Störungen erhöhen.

- Defektraten in SiC-Substraten führen oft zu schlechten Ausbeuten und erhöhen die Produktionsineffizienzen.

- Ereignisse wie die COVID-19 Pandemie haben Schwächen in globalen Lieferketten aufgedeckt und die Notwendigkeit von adaptierbaren Beschaffungsstrategien betont.

Diese Zwänge schaffen Engpässe, die die Verfügbarkeit von SiC-Produkten und das Verlangsamen des Industriewachstums beeinflussen.

High Production Costs

Die Herstellung von Siliciumcarbid ist aufgrund der Komplexität seines Herstellungsprozesses aufwendig. Mehrere Faktoren tragen zu diesen hohen Kosten bei

| Faktor | Beschreibung |

|---|---|

| Rohstoffkosten | Schwankungen in den Erdölkoks- und Siliziummetallpreisen die gesamtkosten beeinflussen. |

| Manufacturing Process | Energieintensive und mehrstufige Prozesse erhöhen die Produktionskosten. |

| Produktionsvolumen | Kleinere Produktionsmengen führen zu höheren Kosten pro Kilogramm. |

| Qualität und Reinheit | Erzielung hoher Reinheit SiC erfordert strenge Standards, steigende Kosten. |

| Marktbedingungen | Ungleichgewichte und wirtschaftliche Faktoren beeinflussen die Preisgestaltung. |

Diese Herausforderungen machen es für kleinere Hersteller schwierig, zu konkurrieren und Marktführer wie Semicera zu beherrschen.

Chancen für Wachstum

Erweiterung von Anwendungen in Schwellenländern

Schwellenländer präsentieren spannende Möglichkeiten für Siliziumkarbid. Die verschiebung in richtung elektromobilität hat einen Anstieg der Nachfrage nach einer effizienten Leistungselektronik geschaffen, wo SiC-Halbleiter ausgezeichnet sind. Erneuerbare Energiesysteme, wie Solar- und Windenergie, verlassen sich auch auf SiC zur Stromumwandlung.

- Die EV-Industrie treibt Wachstum in SiC-Halbleitergeräten an, insbesondere in infrastruktur.

- Industrieautomatisierung und IoT-Geräte benötigen zunehmend SiC-basierte Leistungselektronik.

- Länder wie China, Indien und Südostasien erweitern ihre Halbleiterindustrien und bieten lukrative Möglichkeiten für SiC-Hersteller.

Durch die Einführung in diese Märkte können Unternehmen neue Umsatzströme freischalten und Innovationen vorantreiben.

Potential für Technologisch Durchbrüche

Technologische Fortschritte haben großes Potenzial für die SiC-Industrie. Erhöhte FuE-Bemühungen, unterstützt von Initiativen wie der US-Abteilung für Energieförderung, zielen darauf ab, die materiellen Fähigkeiten zu verbessern.

- SiC-Geräte sind Umformungs-Leistungselektronik, bietet überlegene Effizienz und thermische Beständigkeit im Vergleich zu herkömmlichen Silizium.

- Innovationen in Fertigungsprozessen ermöglichen die Entwicklung von Produkten der nächsten Generation mit verbesserter Leistung.

- Der wachsende EV-Markt erhöht weiterhin die Nachfrage nach SiC und treibt weitere Fortschritte in der Ladeinfrastruktur und in den Kraftwerken voran.

Diese Durchbrüche werden nicht nur die Produktionskosten senken, sondern auch das Anwendungsspektrum für Siliziumkarbid erweitern, was seine Relevanz in zukünftigen Technologien gewährleistet.

Semiceras Führung im Siliziumkarbidmarkt hat die Industriestandards neu definiert. Ihre unübertroffenen produktionskapazitäten die wachsende Nachfrage nach SiC-Wafern über Anwendungen wie Elektrofahrzeuge und erneuerbare Energien. Indem sie R&D priorisieren, treiben sie Innovation an und verbessern die Effizienz und Leistung von SiC-Geräten. Dieser Einfluss prägt die Marktdynamik und gewährleistet eine nachhaltige Zukunft für die Industrie.

Die Fortschritte in SiC-coated susceptors diesen Fortschritt widerspiegeln. Diese für MOCVD-Prozesse wesentlichen Komponenten bieten nun eine überlegene thermische Stabilität und Energieeffizienz. Da die Nachfrage nach Breitband-Halbleitern steigt, werden diese Angreifer eine zentrale Rolle bei der Unterstützung energieeffizienter Technologien spielen. Die Zukunft der SiC-Branche birgt enormes Potenzial, mit technologischen Durchbrüchen und erweiterten Anwendungen, die den Weg für weiteres Wachstum ebnen.

FAQ

Was macht Semicera zum größten Siliziumkarbidhersteller im Jahr 2025?

Semicera führt den Markt aufgrund seiner unübertroffenen Produktionskapazität, ihrer R&D und strategischen Partnerschaften. Seine fortschrittlichen SiC-Beschichtungstechnologien gewährleisten eine überlegene Produktqualität und -leistung. Diese Faktoren positionieren Semicera als Zulieferer für Industrien wie Halbleiter und erneuerbare Energien.

Wie profitieren SiC-beschichtete Suszeptoren von der Halbleiterfertigung?

SiC-beschichtete Suszeptoren verbessern die thermische Effizienz und Haltbarkeit bei Hochtemperaturprozessen wie MOCVD. Sie gewährleisten eine gleichmäßige Wärmeverteilung und verbessern die Qualität epitaktischer Schichten. Diese Zuverlässigkeit unterstützt die Herstellung fortschrittlicher Halbleiter, darunter GaN-Filme für LEDs und Leistungselektronik.

Welche Branchen verlassen sich auf SiC-beschichtete Suszeptoren?

Halbleiter, Erneuerbare Energien und Hochtemperatur-Industrieprozesse hängen von SiC-coated susceptors. Diese Komponenten spielen eine entscheidende Rolle bei der Herstellung von Solarzellen, Leistungselektronik und fortschrittlichen Halbleitern. Ihre Fähigkeit, extremen Bedingungen standzuhalten, macht sie in diesen Sektoren unverzichtbar.

Wie gewährleistet Semicera eine gleichbleibende Produktqualität?

Semicera implementiert strenge Qualitätskontrollmaßnahmen in jeder Produktionsphase. Die ISO 9001:2015-Zertifizierung spiegelt ein Engagement für Exzellenz wider. Erweiterte Engineering- und präzise Fertigungsprozesse garantieren, dass jedes Produkt den höchsten Industriestandards entspricht und Zuverlässigkeit und Kundenzufriedenheit gewährleistet.

Mob: +86-17386007648 Whats APP: +86-17386007648 Email: sales003@china-vet.com