Ever wondered how we achieve those high-purity layers in semiconductor materials? The answer lies in the epitaxy growth susceptor. This fascinating component plays a pivotal role in epitaxial reactors, where it helps grow semiconductor layers with precision. By managing heat and ensuring uniformity, susceptors create the perfect environment for material growth. The demand for these susceptors is skyrocketing, driven by advancements in semiconductor technology. In fact, the market is projected to grow from 2.5 billion in 2023 to 4.8 billion by 2032. It’s an exciting time for this technology!

Key Takeaways

- Epitaxy growth susceptors are essential for achieving high-purity layers in semiconductor materials, ensuring precise atomic arrangements during the growth process.

- These susceptors play a critical role in heat management, maintaining consistent temperatures for uniform layer growth, which is vital for producing reliable semiconductor devices.

- The technology enhances efficiency in semiconductor manufacturing by minimizing defects, leading to cost-effective production and improved yield.

- In LED manufacturing, susceptors contribute to brighter and more energy-efficient products by ensuring uniform deposition of thin films.

- Epitaxy growth susceptors also boost energy conversion efficiency in solar cell production, supporting the development of advanced renewable energy solutions.

- Continuous innovations in susceptor design promise to enhance thermal properties and durability, driving future advancements in semiconductor technology.

- The market for epitaxy growth susceptors is projected to grow significantly, reflecting the increasing demand for high-performance semiconductor devices across various industries.

Understanding Epitaxial Growth Susceptor Technology

Let’s dive into the fascinating world of epitaxy growth susceptor technology. This technology is at the heart of semiconductor manufacturing, and it plays a crucial role in creating high-quality materials.

The Basics of Epitaxial Growth

Definition and Process

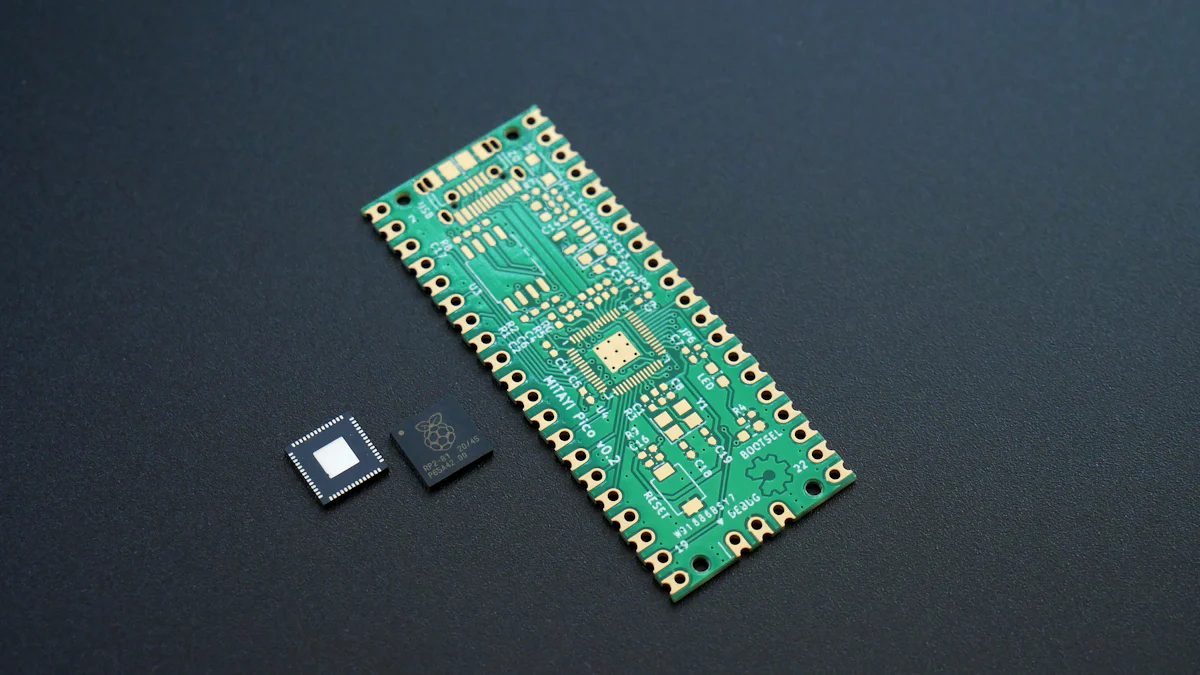

Epitaxial growth refers to the process of depositing a crystalline layer on a substrate crystal. This method ensures that the deposited layer follows the same crystallographic orientation as the substrate. I find this process intriguing because it allows for the creation of layers with precise atomic arrangements. The epitaxy growth susceptor holds the substrate in place during this process, ensuring stability and uniformity.

Importance in Material Science

In material science, epitaxial growth is a game-changer. It enables the production of semiconductor devices with superior electrical properties. By using an epitaxy growth susceptor, we can achieve layers with minimal defects, which is essential for high-performance applications. This technology is pivotal in advancing fields like 5G, IoT, and AI, where precision and efficiency are paramount.

Role of Susceptors in Epitaxial Growth

Heat Management and Uniformity

The epitaxy growth susceptor is not just a holder; it plays a vital role in heat management. It ensures that the temperature remains consistent across the substrate, which is crucial for uniform layer growth. I’ve seen how custom-shaped susceptors enhance this process, leading to better quality layers. This uniformity is essential for producing reliable semiconductor devices.

Material Compatibility and Efficiency

Material compatibility is another area where susceptors shine. They are designed to work seamlessly with various materials, including silicon carbide and graphite. This compatibility ensures efficient epitaxial growth, reducing the risk of defects. The continuous innovation in susceptor design has made them indispensable in modern semiconductor manufacturing. They enable us to push the boundaries of what’s possible in technology.

Applications of Epitaxial Growth Susceptor Technology

The epitaxy growth susceptor plays a vital role in various industries. Its ability to manage heat and ensure uniformity makes it indispensable in several high-tech applications. Let’s explore how this technology enhances different sectors.

Semiconductor Industry

In the semiconductor industry, the epitaxy growth susceptor is a game-changer. It significantly boosts chip performance by ensuring precise layer deposition. I’ve seen firsthand how susceptors help create high-quality semiconductor wafers. They provide the perfect environment for growing thinly doped epi layers over thickly-doped silicon substrates. This process enhances the electrical characteristics of chips, making them faster and more efficient.

Moreover, susceptors contribute to cost-effectiveness in production. By minimizing defects and ensuring uniform growth, they reduce waste and improve yield. This efficiency translates to lower production costs, which is crucial in a competitive market. The relentless demand for smaller and more powerful devices drives the adoption of advanced susceptor technologies.

LED Manufacturing

LED manufacturing also benefits greatly from epitaxy growth susceptor technology. Susceptors improve light output and efficiency by ensuring uniform deposition of thin films. I’ve noticed that this uniformity leads to brighter and more energy-efficient LEDs. The precise control over the growth process minimizes defects, resulting in higher-quality products.

Reducing manufacturing defects is another significant advantage. Susceptors help maintain consistent temperatures, which is essential for producing reliable LEDs. This consistency reduces the likelihood of defects, ensuring that each LED meets high-quality standards. The result is a more efficient production process and superior end products.

Solar Cell Production

In solar cell production, epitaxy growth susceptors increase energy conversion efficiency. They provide a stable environment for growing high-quality layers, which is crucial for efficient solar cells. I’ve observed how susceptors enhance the performance of solar panels by ensuring even thermal distribution during the growth process.

Innovations in thin-film solar cells also rely on susceptor technology. Advanced susceptor designs with enhanced thermal properties and durability support the development of cutting-edge solar cells. These innovations lead to more efficient and longer-lasting solar panels, contributing to the growth of renewable energy solutions.

Epitaxy growth susceptor technology has revolutionized semiconductor manufacturing. It ensures precise layer deposition, enhancing the performance of chips, LEDs, and solar cells. I’ve seen how this technology minimizes defects and boosts efficiency across industries. Looking ahead, innovations in susceptor design promise even greater advancements. Manufacturers are developing susceptors with improved thermal properties and durability. These enhancements will drive the adoption of newer designs, offering a competitive edge. The future of epitaxy growth susceptor technology looks bright, with endless possibilities for innovation and growth.

FAQ

What are the different types of susceptors used in epitaxial growth processes?

In epitaxial growth, we use various types of susceptors to cater to different needs. These include round susceptors, square susceptors, and custom-shaped susceptors. Each type serves a unique purpose, ensuring optimal conditions for material growth.

What role do silicon epitaxy susceptors play in the semiconductor industry?

Silicon epitaxy susceptors are crucial in the semiconductor industry. They create the precise thermal environment needed for epitaxial growth. This precision is vital for producing high-quality semiconductor wafers, which are the backbone of modern electronic devices.

How is the silicon epitaxial susceptor market segmented?

The silicon epitaxial susceptor market is segmented by product type. We see categories like graphite susceptors, silicon carbide (SiC) susceptors, molybdenum susceptors, and others. Each segment caters to specific applications and requirements in the industry.

What drives the growth of the LED epitaxy graphite susceptor market?

Several factors drive the growth of the LED epitaxy graphite susceptor market. The demand for custom-shaped susceptors, the increasing complexity of semiconductor devices, and the industry’s push for miniaturization and performance enhancement all contribute to this growth.

What challenges does the silicon epitaxial susceptor market face?

The silicon epitaxial susceptor market faces a few challenges. High costs associated with advanced susceptor materials and manufacturing processes pose significant hurdles. Additionally, meeting the stringent quality and performance standards required in semiconductor and electronic manufacturing remains a challenge.

What specialized methods are used to produce silicon epitaxial susceptors?

Producing silicon epitaxial susceptors involves specialized methods. We employ precise shaping, advanced machining techniques, and meticulous surface preparation to ensure the highest quality and performance.

What role do silicon epitaxial susceptors play in advanced semiconductor device production?

Silicon epitaxial susceptors are vital in producing advanced semiconductor devices. They enable the creation of superior silicon wafers, which are essential for high-performance applications in various electronic devices.

What drives the market for silicon carbide susceptors?

The market for silicon carbide susceptors is driven by the growing demand for high-performance silicon carbide semiconductors. These semiconductors are crucial in various power and electronic applications, fueling the need for reliable and efficient susceptors.