China plays a crucial role in the global revestimiento de carburo de silicio industry. Identifying the leading manufacturers of silicon carbide coating in China by 2025 ensures businesses stay competitive in a rapidly evolving market. These manufacturers drive innovation and supply high-quality silicon carbide coating materials to meet growing industrial demands. Silicon carbide coating enhances durability and efficiency across industries like automotive, electronics, and aerospace. The silicon carbide coating factory ecosystem in China also supports global trade through silicon carbide layers export, solidifying the nation’s position as a leader in advanced materials.

Key Takeaways

- China’s market for silicon carbide coatings may reach $3.63 billion by 2025. This is due to high demand from car and electronics industries.

- These coatings make things last longer and work better. They are important for electric cars, computer chips, and green energy tools.

- New technology, like chemical vapor deposition, makes coatings stronger and more useful. This helps in making high-quality products.

- Companies should spend on research, build global partnerships, and use eco-friendly methods to succeed in this market.

- China’s strong factories and government help make it a top player in the world silicon carbide coating business.

Overview of the Silicon Carbide Coating Market in China

Market Size and Growth Projections

The silicon carbide coating market in China is experiencing rapid growth. Projections indicate that the market will reach USD 3.63 billion by 2025. By 2030, it is expected to expand further to USD 5.85 billion, with a compound annual growth rate (CAGR) exceeding 10%. This growth is driven by increasing demand from industries such as steel manufacturing, electronics, and automotive.

Historical data highlights the consistent expansion of this market. The table below provides an overview of market revenue and sales data over recent years:

| Año | Market Revenue | Sales Data |

|---|---|---|

| 2017 | N/A | N/A |

| 2018 | N/A | N/A |

| 2019 | N/A | N/A |

| 2020 | N/A | N/A |

| 2021 | N/A | N/A |

| 2024 | Predictions | N/A |

Key Industries Driving Demand

Several industries are fueling the demand for silicon carbide coatings in China:

- Semiconductor Industry: These coatings enhance the performance and durability of semiconductor devices.

- Electronics Sector: They improve the efficiency and lifespan of electronic components.

- Automotive Industry: Electric and hybrid vehicles increasingly rely on silicon carbide coatings for powertrain components and battery systems.

- Energy Sector: Renewable energy technologies, particularly solar power, benefit from the durability and performance of these coatings.

Role of Silicon Carbide Coatings in Industrial Applications

Silicon carbide coatings play a vital role in various industrial applications. They are widely used in automotive, aerospace, electronics, and medical sectors. These coatings provide alta resistencia térmica, exceptional durability, and enhanced efficiency. For instance, in the automotive industry, they improve the performance of electric vehicle components. In aerospace, they protect critical parts from extreme temperatures and wear. Their versatility and economic impact make them indispensable across multiple industries.

Key Market Drivers and Trends

Advancements in Silicon Carbide Coating Technologies

Technological advancements are transforming the silicon carbide coating industry. Innovations in deposition techniques, such as chemical vapor deposition (CVD) and physical vapor deposition (PVD), have improved coating quality and efficiency. These methods enhance the thermal conductivity and durability of coatings, making them suitable for high-performance applications.

A growing focus on nanotechnology has also contributed to the development of advanced silicon carbide coatings. These coatings offer superior resistance to wear and corrosion, which is essential for industries operating in harsh environments. The table below highlights key market drivers that validate the importance of these advancements:

| Market Driver | Explanation |

|---|---|

| Growing Demand for Electric Vehicles (EVs) | The rise in EV demand necessitates high-performance materials like silicon carbide coatings for better efficiency. |

| Advancements in Power Electronics | Enhanced thermal conductivity and efficiency of semiconductor devices drive the need for silicon carbide coatings. |

| High-Temperature and Harsh Environment Applications | Silicon carbide coatings provide protection in extreme conditions, increasing demand in aerospace and manufacturing sectors. |

Demand from Automotive and Electronics Sectors

The automotive and electronics sectors are major contributors to the growth of the silicon carbide coating market. The shift towards electric vehicles (EVs) has increased the need for efficient power electronics, where silicon carbide coatings play a critical role.

- The market is projected to grow from $1.2 billion in 2023 to $3.5 billion by 2032, with a compound annual growth rate (CAGR) of 12.5%.

- The automotive sector relies on these coatings to enhance the performance of EV powertrain components.

- In the electronics sector, silicon carbide coatings are essential for high-frequency and high-temperature applications due to their superior electrical properties.

These trends underline the importance of silicon carbide coatings in meeting the demands of modern industries.

Government Policies Supporting Advanced Materials

Government policies in China have significantly impacted the demand for advanced materials like silicon carbide coatings. Favorable incentives and regulations encourage the adoption of these materials across various industries.

- Policies promoting the development of electric vehicles have boosted the demand for silicon carbide coatings in the automotive sector.

- Support for renewable energy projects has further increased the use of these coatings in solar and wind energy applications.

These initiatives highlight the government’s role in fostering innovation and growth in the silicon carbide coating industry.

Challenges in the Silicon Carbide Coating Industry

High Production Costs and Resource Constraints

The silicon carbide coating industry faces significant challenges due to high production costs and limited resources. Manufacturing these coatings requires advanced equipment and precise processes, which increase expenses. For instance, chemical vapor deposition (CVD), a common method for producing silicon carbide coatings, demands temperatures exceeding 2,000°C. This energy-intensive process contributes to rising costs, especially in regions like Europe, where electricity prices have surged.

Resource constraints further complicate production. The supply chain for high-purity raw materials is often disrupted by geopolitical factors and market volatility. Limited access to these materials delays production and raises costs. Achieving consistent quality also requires significant investment in time and technology, which impacts the industry’s growth potential.

Competition Among Domestic and Global Players

The silicon carbide coating market is highly competitive, with domestic and international manufacturers vying for market share. Chinese companies face pressure to innovate and maintain cost efficiency while competing with established global players. Changing consumer preferences and supply chain disruptions add to this challenge.

Global manufacturers often leverage advanced technologies and economies of scale to dominate the market. However, domestic companies in China are rapidly adopting innovative strategies to stay competitive. These include investing in research and development and forming strategic partnerships to enhance their capabilities.

Environmental and Sustainability Challenges

Environmental regulations pose another significant hurdle for the silicon carbide coating industry. Strict rules govern waste management and the handling of abrasive dust generated during production. Compliance with these regulations increases operational costs and requires continuous investment in eco-friendly technologies.

Sustainability concerns also affect the industry. The higher cost of silicon carbide abrasive paper compared to alternatives like aluminum oxide limits its adoption in some markets. Supply chain disruptions further exacerbate these challenges, impacting the availability of raw materials. Despite these obstacles, technological advancements are helping manufacturers reduce costs and adopt greener production methods.

Leading Silicon Carbide Coating Manufacturers in China

Overview of Top Manufacturers

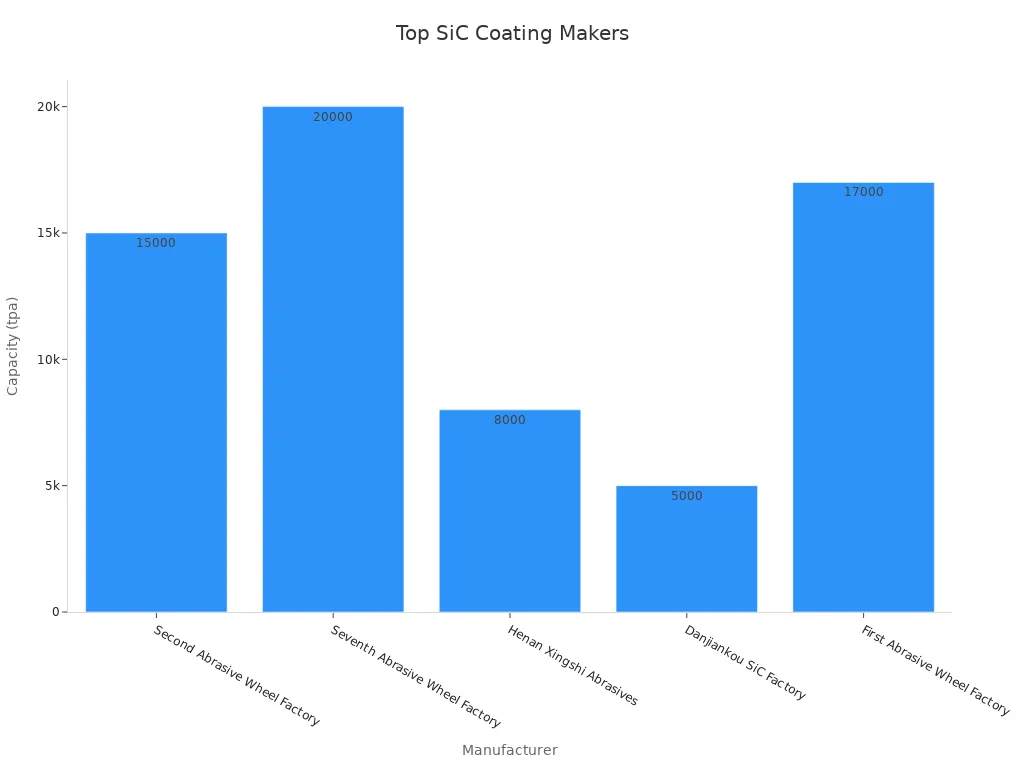

China is home to several leading manufacturers of silicon carbide coating materials. These companies play a pivotal role in meeting the growing demand for advanced coatings across industries. The table below highlights some of the top manufacturers, their production capacities, and focus areas:

| Manufacturer | Production Capacity (tpa) | Focus Area |

|---|---|---|

| Second Abrasive Wheel Factory | 15,000 | Abrasive tools (internal use) |

| Seventh Abrasive Wheel Factory | 20,000 | Abrasive tools |

| Henan Xingshi Abrasives | 8,000 | N/A |

| Danjiankou SiC Factory | 5,000 | N/A |

| First Abrasive Wheel Factory | 17,000 | N/A |

| Total Chinese Processing Capacity | 150,000 | N/A |

These manufacturers contribute significantly to the global silicon carbide coating supply chain. Their combined efforts ensure that industries such as automotive and electronics have access to high-quality materials.

Competitive Strategies and Innovations

Chinese manufacturers employ various strategies to maintain their competitive edge. Many invest heavily in research and development to improve the quality and efficiency of silicon carbide coatings. Advanced deposition techniques, such as chemical vapor deposition (CVD), are widely adopted to enhance product performance.

Collaboration with academic institutions and technology firms is another common approach. These partnerships foster innovation and help manufacturers stay ahead in a rapidly evolving market. Additionally, companies focus on scaling production to meet the increasing demand from industries like automotive and renewable energy.

Case Studies of Successful Companies

The Seventh Abrasive Wheel Factory stands out as a leader in the silicon carbide coating industry. With a production capacity of 20,000 tpa, the company specializes in abrasive tools and has established a strong presence in both domestic and international markets. Its commitment to innovation and quality has earned it a reputation as a reliable supplier.

Another notable example is the Second Abrasive Wheel Factory. This manufacturer focuses on internal use abrasive tools and has a production capacity of 15,000 tpa. By leveraging advanced technologies and maintaining strict quality control, the company has achieved significant success in the industry.

These case studies highlight the importance of innovation, quality, and strategic planning in achieving success in the silicon carbide coating market.

China’s Role in the Global Silicon Carbide Coating Market

Comparison with Other Leading Countries

China stands out in the global silicon carbide coating market due to its cost-competitive production and the longer service life of silicon-infiltrated silicon carbide (SiSiC) kiln furniture. However, regulatory challenges and export controls on high-purity silicon carbide limit its potential in some markets.

A comparison with other leading countries highlights China’s strengths and areas for improvement:

| Country | Fuerza | Weaknesses |

|---|---|---|

| China | Cost-competitive production, longer service life of SiSiC kiln furniture | Regulatory challenges, export controls on high-purity silicon carbide |

| Japón | Advanced in high-tech applications, ultra-fine grain SiSiC ceramics | Dependency on hybrid composites due to supply imbalances |

| Alemania | Specialization in large-format SiSiC components, high mechanical strength | Potential lag in cost-competitiveness compared to Chinese suppliers |

This comparison underscores China’s leadership in cost efficiency while highlighting opportunities to address regulatory and export challenges.

Export Capabilities and Global Partnerships

China’s export capabilities in silicon carbide coating materials have positioned it as a key player in the global market. Chinese manufacturers supply high-quality coatings to industries worldwide, including automotive, electronics, and renewable energy. Strategic partnerships with international companies further enhance China’s global reach.

For example, collaborations with European and American firms have enabled Chinese manufacturers to expand their technological expertise. These partnerships also facilitate the exchange of knowledge and resources, fostering innovation. Additionally, China’s ability to undercut prices in the silicon carbide wafer market has made it a preferred supplier for many global industries. Prices have dropped from USD 1,500 to as low as USD 500 per wafer, making Chinese products highly competitive.

Impact of China’s Manufacturing Ecosystem

China’s robust manufacturing ecosystem plays a crucial role in the success of its silicon carbide coating industry. Several factors contribute to this success:

- China’s solar manufacturing capabilities dominate the global market, accounting for over 70% of polysilicon production and 80% of solar panel manufacturing capacity.

- The annual production of silicon carbide ceramics in China exceeds 150,000 metric tons.

- Jiangxi Province alone hosts 40 specialized manufacturers supplying crucibles to major solar ingot producers.

- Government mandates aim for 1,200 GW of solar and wind capacity by 2030, ensuring sustained demand for high-performance ceramic components.

These factors highlight the synergy between China’s manufacturing ecosystem and its silicon carbide coating industry. The country’s ability to produce high-quality materials at scale, combined with strong government support, ensures its continued dominance in the global market.

Future Outlook for Silicon Carbide Coating Industry by 2025

Predicted Market Growth and Opportunities

The silicon carbide coating industry is poised for significant growth by 2025. Market projections indicate that the global silicon carbide market will grow from USD 3.57 billion in 2023 to USD 3.94 billion in 2024, with a compound annual growth rate (CAGR) of 10.64%. By 2030, the market is expected to reach USD 7.25 billion. Key drivers include the rising demand for energy-efficient appliances, the global shift toward electric and hybrid vehicles, and the expansion of renewable energy infrastructure.

The Asia-Pacific region is expected to lead in growth, driven by advancements in manufacturing and increasing industrial demand. Meanwhile, North America and Europe remain dominant markets due to their established aerospace and automotive sectors. Industries such as aerospace, automotive, and semiconductors present lucrative opportunities. For example, the aerospace industry requires silicon carbide coatings for turbine blades that endure high wear and thermal stress. Similarly, the automotive sector’s transition to electric vehicles increases the need for high-performance materials like silicon carbide coatings for battery components and motors.

Potential Technological Breakthroughs

Technological advancements are set to revolutionize the silicon carbide coating industry. Aerospace manufacturers are adopting binder jet 3D printing to produce complex silicon carbide ceramic matrix composite parts. This innovation enhances the efficiency and precision of silicon carbide coatings.

The development of cubic silicon carbide (3C-SiC) technology is another breakthrough. This technology drives demand for specialized slurries, particularly in semiconductor applications. Additionally, innovations in energy storage systems have led to the use of silicon carbide-coated separators. These separators play a critical role in preventing thermal runaway, showcasing the material’s importance in energy safety and efficiency.

Strategic Recommendations for Stakeholders

Stakeholders in the silicon carbide coating industry should focus on three key strategies to capitalize on future opportunities:

- Invest in Research and Development: Companies should prioritize advancements in coating technologies, such as 3D printing and 3C-SiC, to stay competitive.

- Expand Global Partnerships: Collaborating with international firms can enhance technological expertise and market reach.

- Adopt Sustainable Practices: Emphasizing eco-friendly production methods can help meet regulatory requirements and appeal to environmentally conscious consumers.

By implementing these strategies, stakeholders can position themselves for success in a rapidly evolving market.

The silicon carbide coating market in China demonstrates remarkable growth potential. Key findings highlight the nation’s leadership in cost-effective production and technological advancements. Leading manufacturers, such as the Seventh Abrasive Wheel Factory, excel by adopting innovative strategies like research collaborations and scaling production.

Insight: China’s robust manufacturing ecosystem and government support create a strong foundation for future expansion.

Stakeholders should focus on innovation, global partnerships, and sustainable practices to seize emerging opportunities. By 2025, the industry is poised to redefine global standards in advanced materials.

FAQ

What is silicon carbide coating?

Recubrimiento de carburo de silicona is a protective layer made from silicon carbide material. It enhances durability, thermal resistance, and efficiency in industrial applications. Industries like automotive, aerospace, and electronics use it to improve the performance and lifespan of components.

Why is China a leader in silicon carbide coating production?

China excels due to its cost-effective manufacturing, advanced technologies, and strong government support. Its robust manufacturing ecosystem and high production capacity make it a global leader in silicon carbide coating materials.

Which industries benefit most from silicon carbide coatings?

Industries such as automotive, electronics, aerospace, and renewable energy benefit significantly. These coatings improve the durability and efficiency of components, especially in electric vehicles, semiconductors, and solar energy systems.

What are the key technologies used in silicon carbide coating production?

Technologies like chemical vapor deposition (CVD) and physical vapor deposition (PVD) are widely used. These methods ensure high-quality coatings with superior thermal resistance and durability, suitable for demanding industrial applications.

How can stakeholders capitalize on the growing silicon carbide coating market?

Stakeholders should invest in research and development, form global partnerships, and adopt sustainable practices. These strategies will help them stay competitive and meet the increasing demand for advanced materials in various industries.