Silicon film has revolutionized the way we interact with technology. Its unique properties as a semiconductor have made it indispensable in industries like energy and electronics. In the 1950s, Bell Laboratories created the first practical solar cell using silicon, marking a pivotal moment in renewable energy. Later, breakthroughs in thin-film deposition techniques enabled the development of amorphous silicon, which became a cornerstone for modern solar panels and displays. Today, silicon film continues to drive innovation, shaping advancements in microelectronics, nanotechnology, and sustainable energy solutions.

Key Takeaways

- Silicon film technology has transformed industries by enabling efficient energy solutions and advanced electronics.

- The development of thin-film technology has made solar panels more cost-effective and adaptable, paving the way for widespread adoption.

- Amorphous silicon thin-film solar cells offer flexibility and lower production costs, making them ideal for large-scale applications.

- Innovative deposition techniques like Chemical Vapor Deposition (CVD) and Atomic Layer Deposition (ALD) are crucial for producing high-quality silicon films.

- Silicon film is essential in modern microelectronics, enhancing the performance of transistors and integrated circuits.

- Emerging technologies, such as tandem solar cells and perovskite-silicon hybrids, promise to further increase the efficiency of solar energy solutions.

- Ongoing research aims to overcome challenges in silicon film technology, focusing on improving durability and efficiency for future applications.

The Early Foundations of Silicon Film

The Discovery of Silicon and Its Semiconductor Properties

Silicon, the second most abundant element on Earth, has played a transformative role in modern technology. Its journey began in the early 19th century when scientists first isolated it from silica. However, its true potential as a semiconductor material emerged much later. In the mid-20th century, researchers discovered that silicon’s unique ability to conduct electricity under certain conditions made it ideal for electronic applications. This discovery marked a turning point in the development of transistors, which became the building blocks of modern electronics.

In the 1950s, silicon gained prominence in the transistor industry. Its superior thermal stability and abundance made it the preferred material over germanium, which had been used previously. This shift laid the groundwork for the rapid advancement of microelectronics. Around the same time, Bell Laboratories achieved a historic milestone by creating the first practical silicon solar cell with an efficiency of 6 percent. This innovation demonstrated silicon’s versatility, not just in electronics but also in renewable energy applications.

The Emergence of Thin-Film Technology

Transitioning from Bulk Silicon to Thin-Film Applications

The transition from bulk silicon to thin-film technology represented a significant leap in material science. Bulk silicon, while effective, posed challenges due to its high material costs and limited flexibility. Thin-film technology emerged as a solution, offering a more economical and versatile alternative. By depositing ultra-thin layers of silicon onto substrates like glass or metal, researchers could achieve similar functionality with reduced material usage.

In 1976, scientists demonstrated amorphous silicon as a viable material for thin-film solar cells. Although these early cells faced challenges, such as weak bonds and lower efficiency compared to crystalline silicon, they opened new possibilities for large-scale applications. Amorphous silicon panels eventually achieved efficiencies of up to 14 percent, proving their potential in the renewable energy sector.

The work of Peter LeComber and Walter Spear further advanced thin-film technology. Their experiments demonstrated the feasibility of using amorphous silicon in flat-panel displays. This breakthrough paved the way for modern liquid crystal displays (LCDs), which rely on thin films for their operation. Thin-film technology also gained traction in solar energy, where its cost-effectiveness and adaptability made it a popular choice.

"Thin-film solar cells are favored for their economic efficiency, material usage, and rising effectiveness," as noted in a comprehensive survey of silicon thin-film applications.

The evolution of thin-film technology highlights the ingenuity of scientists and engineers in overcoming material limitations. By transitioning from bulk silicon to thin films, they unlocked new opportunities in both energy and electronics, setting the stage for future innovations.

Key Milestones in the Development of Silicon Film

The Advent of Silicon Solar Cells

The Invention of the Silicon Solar Cell in the 1950s

The 1950s marked a groundbreaking era for silicon film. Bell Laboratories introduced the first practical silicon solar cell, achieving an efficiency of 6 percent. This innovation demonstrated the potential of silicon in renewable energy. Researchers focused on harnessing silicon’s semiconductor properties to convert sunlight into electricity. This invention laid the foundation for modern solar technology and inspired further advancements in photovoltaic systems.

The early silicon solar cells were bulky and expensive, limiting their widespread adoption. However, their success in powering satellites during the space race showcased their reliability. This milestone proved that silicon film could revolutionize energy generation. It also highlighted the need for more efficient and cost-effective solutions.

The Rise of Amorphous Silicon Thin-Film Technology in the 1980s

The 1980s saw the rise of amorphous silicon thin-film technology. Unlike crystalline silicon, amorphous silicon offered flexibility and lower production costs. By depositing thin layers of silicon onto substrates, manufacturers reduced material usage. This approach made solar panels more affordable and accessible.

Amorphous silicon panels gained popularity due to their adaptability. They achieved efficiencies of up to 14 percent, making them suitable for large-scale applications. By 1986, these panels captured 29 percent of the market share. Their success demonstrated the versatility of silicon film in addressing energy challenges.

"Amorphous silicon thin-film technology revolutionized the solar industry by offering cost-effective and flexible solutions," as noted in industry reports.

Breakthroughs in Deposition Techniques

Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD)

Deposition techniques played a crucial role in advancing silicon film technology. Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) emerged as key methods for creating thin films. CVD involved chemical reactions to deposit materials onto a substrate, ensuring uniformity. PVD, on the other hand, used physical processes like evaporation or sputtering to achieve similar results.

Both techniques enabled the production of high-quality silicon films. CVD became popular for its ability to create dense and uniform layers. PVD offered advantages in depositing materials with high melting points. These methods supported the development of silicon-based devices, including solar cells and microelectronics.

Innovations in Atomic Layer Deposition (ALD)

Atomic Layer Deposition (ALD) represented a significant leap in deposition technology. ALD allowed for precise control over film thickness and composition. It excelled in creating ultrathin, conformal layers, even on complex geometries. This precision made ALD the preferred choice for applications requiring high accuracy.

ALD found applications beyond solar cells. It became essential in optics, magnetic recording, and micro-electromechanical systems. Its ability to deposit uniform films over large areas enhanced the performance of silicon-based devices. ALD’s versatility underscored its importance in the evolution of silicon film technology.

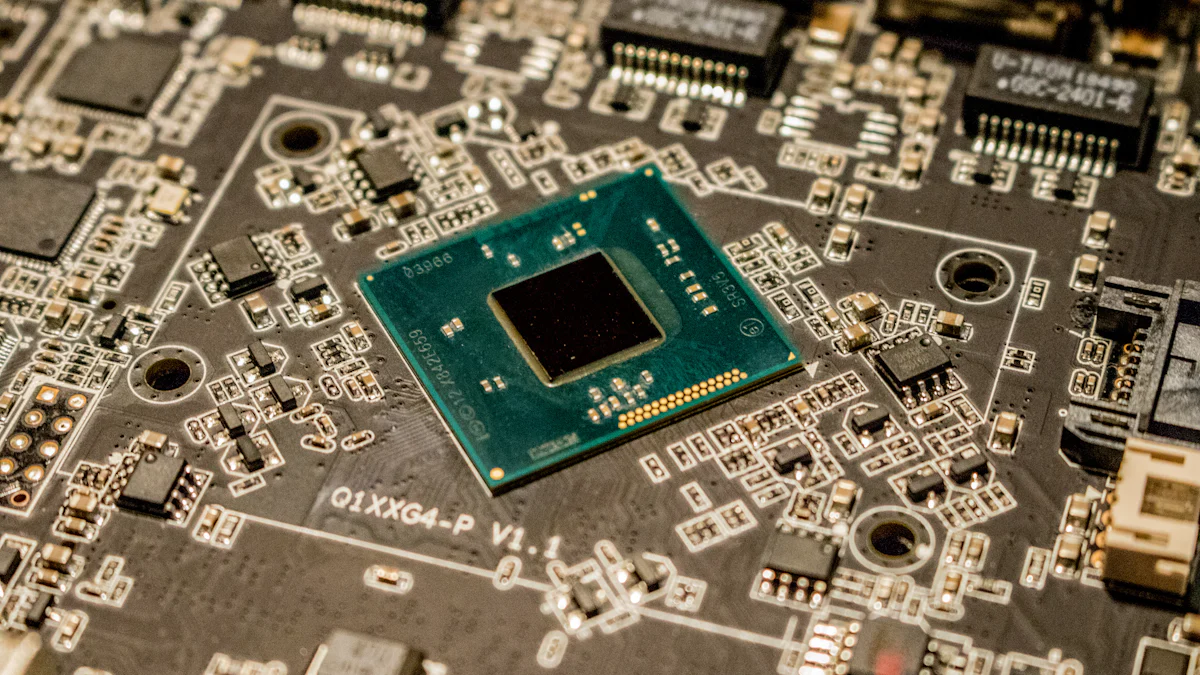

Silicon Film in Microelectronics

Integration in Transistors and Integrated Circuits

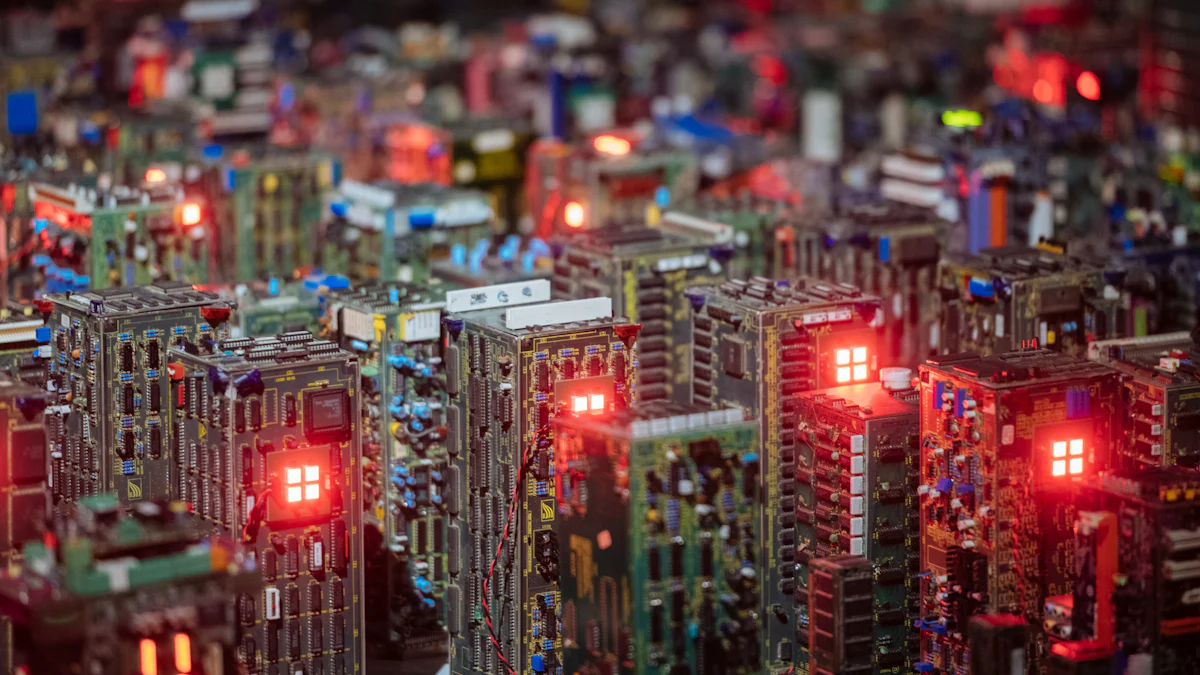

Silicon film transformed the microelectronics industry. It became the backbone of transistors and integrated circuits. By using thin layers of silicon, engineers improved the performance and efficiency of electronic devices. Silicon film enabled the miniaturization of components, paving the way for modern computing.

Transistors made from silicon film offered superior thermal stability and reliability. Integrated circuits, built on silicon wafers, revolutionized data processing. These advancements demonstrated the critical role of silicon film in shaping the digital age.

The Role of Silicon-on-Insulator (SOI) Technology

Silicon-on-Insulator (SOI) technology represented another milestone in microelectronics. SOI involved placing a thin layer of silicon on an insulating substrate. This approach reduced power consumption and improved device performance. SOI technology became essential in applications requiring high-speed and low-power operation.

SOI technology also enhanced the reliability of silicon-based devices. It minimized interference and heat generation, ensuring stable performance. By leveraging silicon film, SOI technology addressed the challenges of modern electronics. Its impact extended to fields like telecommunications, automotive systems, and consumer electronics.

Modern Applications and Future Prospects of Silicon Film

Renewable Energy Applications

Dominance of Silicon-Based Solar Panels

Silicon-based solar panels dominate the renewable energy market due to their efficiency and reliability. Over the decades, these panels have evolved significantly, achieving higher energy conversion rates and longer lifespans. Businesses increasingly adopt these panels to reduce energy costs and carbon footprints. Their widespread use in residential, commercial, and industrial settings highlights their versatility.

Thin-film solar panels, a subset of silicon-based technology, offer unique advantages. Their lightweight and flexible design makes them ideal for integration into building materials, such as rooftops and facades. Researchers at MIT have even developed ultralight fabric solar cells that generate more power per kilogram than traditional panels. These innovations demonstrate the adaptability of silicon film in addressing diverse energy needs.

"Thin-film solar cells are efficient, cost-effective, and show a positive trend in terms of effectiveness," according to a comprehensive review of silicon thin-film solar cells.

Emerging Technologies like Tandem Solar Cells and Perovskite-Silicon Hybrids

The future of solar energy lies in emerging technologies like tandem solar cells and perovskite-silicon hybrids. Tandem solar cells stack multiple layers of materials to capture a broader spectrum of sunlight, boosting efficiency. Researchers are working to integrate these cells into existing manufacturing processes, making them more accessible to the market.

Perovskite-silicon hybrids represent another promising advancement. By combining the high efficiency of perovskites with the stability of silicon, these hybrids could revolutionize solar energy. First Solar, a leader in the industry, is actively exploring this technology to enhance energy conversion rates. These developments underscore the potential of silicon film to drive innovation in renewable energy.

Advancements in Electronics and Nanotechnology

Flexible and Wearable Electronics

Silicon film has transformed the electronics industry, enabling the creation of flexible and wearable devices. Thin-film transistors, made from silicon, power modern displays and sensors. These components are lightweight and adaptable, making them ideal for applications like smartwatches, fitness trackers, and medical devices.

The flexibility of silicon film allows engineers to design devices that conform to the human body. This capability enhances user comfort and expands the possibilities for health monitoring. For instance, wearable electronics equipped with silicon-based sensors can track vital signs in real time, improving healthcare outcomes.

Silicon Films in Quantum Computing and Advanced Sensors

Quantum computing represents the frontier of technological innovation, and silicon film plays a crucial role in its development. Thin layers of silicon provide the precision and stability needed for quantum bits, or qubits, to function effectively. These advancements could lead to breakthroughs in data processing and encryption.

Silicon film also enhances the performance of advanced sensors. From environmental monitoring to autonomous vehicles, these sensors rely on the material’s unique properties. Its ability to detect changes in light, temperature, and pressure makes it indispensable in cutting-edge applications.

Challenges and Future Directions

Overcoming Material Limitations and Enhancing Efficiency

Despite its many advantages, silicon film faces challenges that require ongoing research. Material limitations, such as brittleness and efficiency losses, hinder its performance in certain applications. Scientists are exploring ways to improve the durability and conductivity of silicon-based materials.

Efforts to enhance efficiency focus on reducing energy losses during production and operation. Innovations in deposition techniques, like Atomic Layer Deposition (ALD), offer precise control over film thickness and composition. These advancements aim to maximize the potential of silicon film in both energy and electronics.

Exploring Plasmonics and Other Cutting-Edge Innovations

Plasmonics, an emerging field, holds promise for the future of silicon film technology. By manipulating light at the nanoscale, plasmonics could improve the efficiency of solar cells and sensors. Researchers are investigating how to integrate this technology with silicon-based devices to unlock new possibilities.

Other innovations, such as ultrathin coatings and hybrid materials, also show potential. These developments aim to address current limitations while expanding the applications of silicon film. The journey of this technology continues, driven by the pursuit of efficiency and sustainability.

Silicon film technology has traveled an extraordinary path, evolving from its foundational discoveries to its transformative role in modern industries. It has reshaped energy production, revolutionized electronics, and opened doors in nanotechnology. Thin-film advancements, with their growing market share and potential for higher efficiency, highlight the relentless pursuit of innovation. Researchers continue to refine these technologies, aiming for breakthroughs that could redefine sustainability and performance. The future of silicon film lies in its ability to adapt and innovate, ensuring its relevance in addressing the challenges of tomorrow. This journey reflects the boundless possibilities of human ingenuity.

FAQ

What are the advantages of Amorphous Silicon Thin Film Solar Cells?

Amorphous silicon thin-film solar cells provide several benefits. They cost less to produce compared to crystalline silicon cells. Their flexibility allows integration into various surfaces, including curved or irregular ones. Manufacturers also favor them for large-scale production due to their adaptability and reduced material usage.

How does thin-film technology differ from traditional bulk silicon?

Thin-film technology uses ultra-thin layers of silicon deposited on substrates like glass or metal. This approach reduces material costs and increases flexibility. Traditional bulk silicon, on the other hand, involves thicker, rigid wafers, which are more expensive and less adaptable for certain applications.

Why is silicon the preferred material for solar cells and electronics?

Silicon stands out due to its abundance, thermal stability, and excellent semiconductor properties. It efficiently converts sunlight into electricity in solar cells. In electronics, its ability to conduct electricity under controlled conditions makes it ideal for transistors and integrated circuits.

What role does Atomic Layer Deposition (ALD) play in silicon film technology?

Atomic Layer Deposition (ALD) ensures precise control over film thickness and composition. It creates uniform, ultrathin layers, even on complex surfaces. This precision enhances the performance of silicon-based devices, including solar cells, sensors, and microelectronics.

How has silicon film contributed to advancements in renewable energy?

Silicon film has revolutionized renewable energy by enabling efficient and cost-effective solar panels. Thin-film solar cells, in particular, offer lightweight and flexible solutions. Emerging technologies like tandem solar cells and perovskite-silicon hybrids further expand its potential in capturing solar energy.

What challenges does silicon film technology face today?

Silicon film technology faces challenges like brittleness and efficiency losses. Researchers aim to improve durability and conductivity. Efforts also focus on reducing energy losses during production and operation to enhance overall performance.

Can silicon film be used in wearable electronics?

Yes, silicon film plays a crucial role in wearable electronics. Its flexibility and lightweight nature make it ideal for devices like fitness trackers and medical sensors. These devices benefit from silicon’s ability to conform to the human body, ensuring comfort and functionality.

What is the significance of Silicon-on-Insulator (SOI) technology?

Silicon-on-Insulator (SOI) technology improves device performance by placing a thin silicon layer on an insulating substrate. This reduces power consumption and minimizes interference. SOI technology is essential for high-speed, low-power applications in telecommunications and consumer electronics.

How does plasmonics relate to silicon film technology?

Plasmonics explores the manipulation of light at the nanoscale. When integrated with silicon film, it can enhance the efficiency of solar cells and sensors. This emerging field holds promise for advancing silicon-based technologies.

What future innovations can we expect in silicon film technology?

Future innovations may include hybrid materials, ultrathin coatings, and advancements in deposition techniques. Researchers are also exploring tandem solar cells and quantum computing applications. These developments aim to address current limitations and unlock new possibilities for silicon film.