When it comes to protecting your vehicle, the debate of SiC vs SiO2 ceramic coating can feel overwhelming. Each type of coating offers unique advantages, but understanding their differences is essential. SiC ceramic coating is renowned for its exceptional durability, often lasting over a decade with proper care. It provides superior resistance to scratches and chemicals compared to most alternatives. Meanwhile, SiO2 ceramic coating is a more budget-friendly option, though it requires more frequent maintenance and has a shorter lifespan.

SiC coatings not only deliver a deeper gloss but also ensure superior long-term aesthetics. However, applying SiCコーティング often requires professional expertise, unlike SiO2 coatings, which are more DIY-friendly. Additionally, SiC coating on graphite or SiC coated graphite surfaces is highly valued for its enhanced performance and durability. By understanding these distinctions and the benefits of SiC coating, you can make an informed decision that aligns with your vehicle’s needs and budget.

要点

- SiC ceramic coatings are very strong and can last over 10 years with good care. They are great for long-term car protection.

- SiO2 ceramic coatings cost less and are easier to use. They are good for people who like DIY projects but need more upkeep.

- SiC coatings are better at stopping scratches, chemicals, and heat. They work well in tough conditions.

- SiC coatings make cars look amazing with a shiny, mirror-like finish that improves their look.

- Both coatings need regular care. Wash with gentle soap and avoid strong chemicals to keep them working well.

- Think about your car and how you use it before picking a coating. SiC is best for fancy cars, while SiO2 works for everyday cars needing basic protection.

- SiC coatings cost more at first but save money later because they last longer and need fewer reapplications.

- Remember, ceramic coatings protect cars but don’t stop all scratches or remove the need for care.

What Are Ceramic Coatings?

Definition and Purpose

When I think about ceramic coatings, I see them as a revolutionary solution for vehicle protection. These coatings are advanced formulas made from silicon dioxide (SiO2), which bond semi-permanently to a vehicle’s paint. This bond creates a durable layer that enhances scratch resistance and shields against environmental contaminants.

Ceramic coatings are not just about protection. They also improve the aesthetics of a vehicle. By using nano-technology, these coatings form a hard barrier that resists chips and scratches, rated up to 9H on the pencil scale. I often recommend them as a long-term solution for preserving a car’s paint job. They are typically applied by hand, ensuring thorough coverage and a flawless finish. Whether it’s paint, glass, or even metal, ceramic coatings enhance the surface while providing robust protection.

Benefits for Vehicle Protection

The benefits of ceramic coatings go beyond just durability. From my experience, they significantly reduce maintenance efforts. A ceramic coating creates a hydrophobic surface that repels water and dirt. This means fewer car washes and less time spent cleaning. It also protects the paint from UV rays and oxidation, which slows down the aging process of the car’s exterior.

I’ve seen how these coatings can transform a vehicle’s appearance. The high-gloss finish enhances the overall look, making the car shine like new. This improved aesthetic can even increase the resale value. Many car owners report high satisfaction due to the ease of maintenance and the long-lasting protection these coatings provide. For anyone looking to preserve their vehicle’s condition for years, ceramic coatings are an excellent choice.

Common Misconceptions

Despite their popularity, ceramic coatings are often misunderstood. One common myth I hear is that they make cars completely scratch-proof. While they enhance protection, they don’t eliminate the risk of scratches entirely. Another misconception is that ceramic coatings provide permanent gloss and require no upkeep. In reality, regular maintenance is essential to maintain their effectiveness.

Some people believe that applying a ceramic coating once guarantees lifelong protection. This is misleading. Like sunscreen, these coatings need reapplication over time. I’ve also encountered the belief that ceramic coatings eliminate the need for car washes. This isn’t true. Cars still require cleaning to keep the coating in good condition. Proper preparation before application is another overlooked step. Even new vehicles need thorough prep work to ensure the coating adheres correctly.

By addressing these misconceptions, I aim to help car owners make informed decisions. Ceramic coatings are a powerful tool for vehicle protection, but understanding their limitations is just as important as recognizing their benefits.

SiC Ceramic Coating Overview

What Is SiC Ceramic Coating?

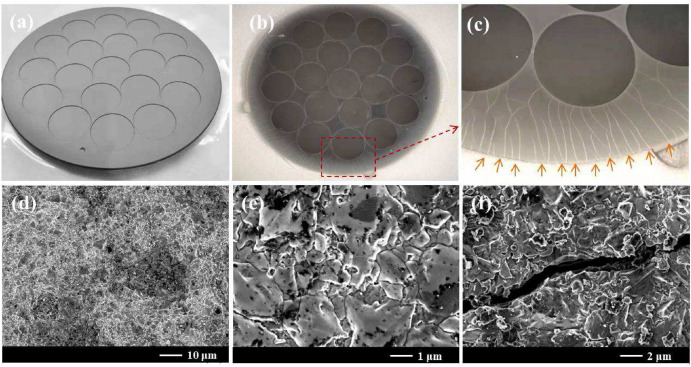

SiC ceramic coating, short for Silicon Carbide ceramic coating, is a cutting-edge solution for vehicle protection. It is crafted from Silicon Carbide, a material celebrated for its extreme hardness and chemical resistance. Unlike traditional SiO2 coatings derived from quartz, SiC coatings offer superior durability and performance. This advanced composition allows it to withstand harsh conditions while maintaining its protective qualities.

I often recommend SiC ceramic coating for its longevity. With proper maintenance, it can last over a decade, far outpacing the lifespan of SiO2 coatings. Its chemical structure not only enhances durability but also provides a deeper, more reflective gloss. This makes it a preferred choice for car enthusiasts who value both protection and aesthetics.

Key Features and Advantages

SiC ceramic coating stands out due to its remarkable features. From my experience, its durability is unmatched. It can endure over ten years of use with minimal degradation. This makes it an excellent investment for long-term vehicle care. Additionally, its resistance to chemicals, scratches, and high temperatures ensures reliable performance in various environments.

Here are some of its key features and benefits:

- Durability: Lasts over a decade with proper care.

- Resistance: Protects against chemicals, scratches, and extreme heat.

- フィニッシュ: Delivers a deep, mirror-like gloss for a showroom-quality appearance.

| Feature | 説明 |

|---|---|

| Exceptional Thermal Resistance | Stable in environments up to 1600°C, ensuring reliable operation in high heat conditions. |

| Superior Chemical Stability | Resists acids, alkalis, and corrosive substances, protecting equipment from chemical erosion. |

| High Mechanical Durability | Hardness approaching that of diamond, providing exceptional wear resistance. |

These qualities make SiC ceramic coating a top-tier choice for vehicle owners who demand the best. Its ability to maintain a pristine finish while offering robust protection sets it apart from other coatings.

Applications in Vehicle Protection

SiC ceramic coating is particularly popular among owners of luxury and high-performance vehicles. I’ve seen it used on cars like the Tesla Model S to enhance their appearance and protect their surfaces. Its ability to repel dirt and grime makes maintenance easier, saving time and effort for car owners.

This coating is ideal for vehicles exposed to harsh conditions. It shields against environmental contaminants, such as road salt and acid rain, ensuring the paint remains intact. I often recommend it for those who want long-lasting protection and a stunning finish. Whether it’s a daily driver or a collector’s car, SiC ceramic coating provides unparalleled benefits.

Smicera Semiconductor (Ningbo Miami Advanced Material Technology Co., LTD) specializes in producing high-end materials like SiC ceramic coatings. Their expertise in advanced materials and surface treatments ensures top-quality products for industries like automotive, semiconductor, and new energy. With a strong R&D team and ISO 9001:2015 certification, Smicera delivers innovative solutions trusted by customers worldwide.

SiO2 Ceramic Coating Overview

What Is SiO2 Ceramic Coating?

SiO2 ceramic coating, or Silicon Dioxide ceramic coating, is a popular choice for vehicle protection. It is derived from quartz and forms a semi-permanent bond with the vehicle’s surface. This coating creates a protective layer that shields the paint from environmental damage. Unlike SiC coatings, SiO2 coatings are more affordable and easier to apply, making them a practical option for many car owners.

私の経験から、, SiO2 coatings offer reliable protection but lack the advanced chemical properties of SiC coatings. They provide a good level of gloss and hydrophobicity, but their durability and shine retention fall short when compared to SiC. For those seeking a balance between cost and performance, SiO2 ceramic coatings are an excellent starting point.

お問い合わせ: While SiO2 coatings are effective, they do not match the superior protection, gloss, and longevity of SiC coatings. Understanding these differences helps in choosing the right solution for your vehicle.

Key Features and Advantages

SiO2 ceramic coatings come with several notable features that make them a popular choice among vehicle owners. Based on my observations, these coatings provide reliable protection and enhance the vehicle’s appearance. Here are some of their key advantages:

- Durability: Offers protection for 1-3 years, depending on maintenance.

- Resistance: Shields against UV rays, light scratches, and environmental contaminants.

- フィニッシュ: Delivers an initial high-gloss appearance with hydrophobic properties, though it may fade over time.

- Ease of Application: Suitable for DIY enthusiasts due to its user-friendly application process.

- 耐久性: A cost-effective option compared to SiC coatings.

These features make SiO2 coatings a practical choice for those who want moderate protection without breaking the bank. However, I always recommend considering the specific needs of your vehicle before making a decision.

Applications in Vehicle Protection

SiO2 ceramic coatings are versatile and cater to a wide range of vehicle protection needs. I often suggest them for daily drivers or vehicles that require moderate protection. Here are some common applications:

- Adding a protective layer to cars used for everyday commuting.

- Protecting vehicles from UV rays, light scratches, and contaminants like dirt and bird droppings.

- Serving as an affordable option for those new to ceramic coatings.

- Enhancing the appearance of vehicles with a glossy finish.

For car owners who prioritize ease of use and affordability, SiO2 coatings are an ideal choice. They provide a solid level of protection while improving the vehicle’s aesthetics.

Smicera Semiconductor (Ningbo Miami Advanced Material Technology Co., LTD) specializes in advanced materials like SiO2 ceramic coatings. Their expertise spans industries such as automotive, semiconductor, and new energy. With ISO 9001:2015 certification and a strong R&D team, Smicera delivers innovative solutions trusted by customers worldwide. Their commitment to quality and cost-effective designs ensures reliable products for vehicle protection and beyond.

Comparing SiC and SiO2 Ceramic Coatings

Durability and Longevity

When it comes to durability, I’ve found that SiC ceramic coatings are in a league of their own. They form an incredibly tough layer that can endure years of wear and tear. Many manufacturers even back this up with lifetime guarantees, which speaks volumes about their reliability. This makes SiC coatings an excellent choice for anyone seeking long-term protection for their vehicle.

On the other hand, SiO2 ceramic coatings, while still durable, don’t quite match the longevity of SiC. These coatings typically last between one to three years, depending on how well they’re maintained. For short-term use or for those who prefer a more budget-friendly option, SiO2 coatings can still provide decent protection. However, I always recommend considering the long-term benefits of investing in a more durable solution like SiC.

- SiC Coatings: Highly durable, often with lifetime guarantees.

- SiO2 Coatings: Durable but better suited for short-term use.

Resistance to Environmental Factors

In my experience, SiC ceramic coatings excel in resisting environmental challenges. Their extreme hardness and chemical resistance make them highly effective against UV rays, road salt, and even harsh chemicals. This level of protection ensures that your vehicle’s paint remains intact and vibrant, even in the harshest conditions.

SiO2 coatings, while offering some resistance, don’t provide the same level of protection. They shield against UV rays and light contaminants but are less effective against more aggressive environmental factors. For vehicles exposed to extreme weather or industrial pollutants, I always recommend SiCコーティング 優秀な性能のため.

チップ: If your vehicle frequently faces harsh conditions, SiC coatings are the better choice for long-lasting protection.

Aesthetic Finish and Gloss

The aesthetic appeal of a vehicle is just as important as its protection. SiC ceramic coatings deliver a deeper, richer gloss that enhances the paint’s color and clarity. I’ve seen how they create a stunning reflective finish, making vehicles look like they just rolled out of a showroom. This makes them a favorite among car enthusiasts who prioritize high-end aesthetics.

SiO2 coatings, while initially glossy, don’t maintain their shine as long as SiC coatings. Over time, the gloss tends to fade, which can affect the vehicle’s overall appearance. For those who want a long-lasting, showroom-quality finish, SiC coatings are the clear winner.

| コーティング・タイプ | Aesthetic Finish | Gloss Characteristics |

|---|---|---|

| SiC | Deeper, richer gloss enhancing paint colors | Stunning clarity and reflection, ideal for high-end aesthetics |

| シオ2 | Great initial gloss | Does not maintain showroom shine as long as SiC, affecting long-term aesthetics |

Smicera Semiconductor (Ningbo Miami Advanced Material Technology Co., LTD) specializes in producing advanced materials like SiC and SiO2 ceramic coatings. Their expertise spans industries such as automotive, semiconductor, and new energy. With ISO 9001:2015 certification and a strong R&D team, Smicera delivers innovative solutions trusted by customers worldwide. Their commitment to quality ensures reliable products for vehicle protection and beyond.

Application Process

Applying ceramic coatings, whether SiC or SiO2, requires precision and attention to detail. I’ve seen how the process can significantly impact the coating’s performance and longevity. While both coatings share some similarities in application, their unique properties demand specific techniques.

-

表面の準備:

Proper preparation is the foundation of a successful application. I always start by thoroughly cleaning the vehicle to remove dirt, grease, and contaminants. Polishing the surface ensures a smooth base, free of imperfections. For SiC coatings, I recommend an even more meticulous approach since their hardness makes them less forgiving of surface flaws. -

応用技術:

SiO2 coatings are more user-friendly and suitable for DIY enthusiasts. They typically come in liquid form and require a simple wipe-on, wipe-off method. SiC coatings, on the other hand, demand professional expertise. Their advanced chemical composition requires precise layering and curing under controlled conditions. I’ve found that using specialized tools, like infrared curing lamps, enhances the bonding process for SiC coatings. -

Curing Time:

Both coatings need adequate curing time to achieve optimal performance. SiO2 coatings usually cure within 24-48 hours, while SiC coatings may take longer due to their complex structure. I always advise avoiding water exposure during this period to ensure the coating bonds effectively.

チップ: For best results, consult a professional for SiC coatings. Their expertise ensures proper application and maximizes the coating’s benefits.

Smicera Semiconductor specializes in advanced materials like SiC and SiO2 coatings. Their innovative technologies and rigorous quality standards make them a trusted choice for high-performance coatings. With a strong R&D team and ISO 9001:2015 certification, Smicera delivers reliable solutions for automotive and other industries.

Cost and Affordability

Cost is often a deciding factor when choosing between SiC and SiO2 ceramic coatings. From my experience, SiO2 coatings are the more affordable option. They cater to car owners seeking moderate protection without a significant financial commitment. Prices for SiO2 coatings typically range from $100 to $500, depending on the brand and application method.

SiC coatings, however, represent a premium investment. Their superior durability, gloss, and resistance justify the higher cost. Professional application services for SiC coatings can range from $1,000 to $2,500 or more. While the upfront cost may seem steep, I always emphasize the long-term savings. SiC coatings require less frequent reapplication and provide unparalleled protection, making them cost-effective over time.

| コーティング・タイプ | Approximate Cost Range | Longevity | Ideal For |

|---|---|---|---|

| シオ2 | $100 – $500 | 1-3 years | Budget-conscious car owners |

| SiC | $1,000 – $2,500+ | 10+ years | Long-term protection enthusiasts |

お問い合わせ: Investing in SiC coatings pays off for luxury or high-performance vehicles. Their durability and aesthetic appeal enhance the vehicle’s value.

Smicera Semiconductor offers cost-effective solutions for both SiC and SiO2 coatings. Their commitment to innovation and quality ensures that customers receive the best value for their investment. By leveraging their expertise in advanced materials, Smicera continues to lead the industry in delivering high-performance coatings.

Choosing the Right Ceramic Coating

Factors to Consider (Vehicle Type, Usage, Climate)

Choosing between SiC and SiO2 ceramic coatings depends on several factors. Vehicle type, usage, and climate play a significant role in determining the best option. For instance, luxury or high-performance vehicles like a Tesla Model S benefit from the durability and aesthetic appeal of SiC ceramic coating. On the other hand, daily drivers such as a Honda CR-V may find SiO2 coatings more practical due to their affordability and ease of application.

Climate also influences the decision. Vehicles in harsh environments with extreme heat, road salt, or industrial pollutants require the superior chemical resistance of SiC coatings. In contrast, SiO2 coatings work well in milder climates where frequent maintenance is manageable. Usage patterns matter too. If you drive long distances or frequently encounter dirt and grime, SiO2 coatings can simplify cleaning. However, for long-term protection and reduced upkeep, SiC coatings are the better choice.

| Feature | SiC | シオ2 |

|---|---|---|

| Durability | Lasts for years, lifetime guarantee | 1-3 years, requires more maintenance |

| Chemical Resistance | Exceptional, withstands harsh conditions | Decent, needs frequent upkeep |

| Gloss and Aesthetics | Deeper, richer gloss | Good initial gloss, less long-lasting |

| Application Difficulty | Requires professional expertise | More accessible for DIY applications |

| コスト | Higher upfront cost, long-term savings | Lower initial cost, short-term solution |

チップ: Consider your vehicle’s value and the environmental conditions it faces before deciding on a coating.

When to Choose SiC Ceramic Coating

SiC ceramic coating is the ideal choice for those seeking long-term protection and unmatched aesthetics. Its exceptional durability makes it perfect for luxury or high-performance vehicles. For example, a Tesla Model S owner shared how the SiC coating not only enhanced the car’s appearance but also made maintenance effortless. Dirt and grime rinsed off easily, even months after application.

This coating excels in challenging environments. Its resistance to harsh chemicals and extreme temperatures ensures reliable performance in tough conditions. If your vehicle frequently faces road salt, acid rain, or industrial pollutants, SiC coating provides the robust protection you need. Additionally, its deeper, richer gloss enhances paint colors, making it a favorite among car enthusiasts.

- Durability: Withstands years of wear and tear, offering long-term value.

- Chemical Resistance: Protects against harsh substances, ideal for extreme climates.

- Aesthetic Appeal: Delivers a showroom-quality finish that lasts.

Smicera Semiconductor specializes in producing high-quality SiC ceramic coatings. Their advanced materials and surface treatments, including CVD SiC coatings, are trusted across industries like automotive, semiconductor, and new energy. With ISO 9001:2015 certification and a strong R&D team, Smicera ensures top-tier solutions for vehicle protection.

When to Choose SiO2 Ceramic Coating

SiO2 ceramic coating is a practical option for daily drivers and those new to ceramic coatings. It provides reliable protection without the need for long-term durability. For instance, a client with a leased vehicle reported that SiO2 coating made cleaning bugs and grime much easier, highlighting its convenience for frequent drivers.

This coating is also ideal for vehicles requiring short-term protection. Lease vehicles or cars used for commuting benefit from its affordability and ease of application. While it doesn’t match the longevity of SiC coatings, it offers a good balance of cost and performance for moderate needs.

- 耐久性: A budget-friendly option for short-term use.

- Ease of Use: Suitable for DIY enthusiasts and first-time users.

- Practical Benefits: Simplifies cleaning and maintenance for frequent drivers.

Smicera Semiconductor also offers cost-effective SiO2 ceramic coatings. Their innovative designs and commitment to quality ensure reliable products for vehicle protection. With expertise in advanced materials and a focus on customer satisfaction, Smicera continues to lead the industry in ceramic coating solutions.

Maintenance Tips for Ceramic Coatings

General Maintenance Guidelines

Maintaining ceramic coatings properly ensures their longevity and effectiveness. I always recommend regular care to preserve the coating’s protective and aesthetic qualities. Here are some essential practices I follow:

- Wash the vehicle regularly using pH-neutral soaps designed for ceramic coatings. This prevents dirt and grime from building up.

- Avoid harsh chemicals or abrasive tools that can damage the coating’s surface.

- Inspect the coating periodically to identify any signs of wear or damage. Addressing issues early can prevent further deterioration.

- Protect the vehicle from harsh environmental factors. Parking in shaded areas reduces exposure to UV rays and contaminants.

- For added protection, consider applying a sacrificial wax or sealant over the ceramic coating.

When washing, I use the two-bucket method to minimize scratches. One bucket holds soapy water, while the other contains clean water for rinsing the wash mitt. After washing, I dry the vehicle thoroughly with a microfiber cloth to avoid water spots. Every few months, I apply a ceramic booster to rejuvenate the coating and maintain its hydrophobic properties.

チップ: Consistent maintenance can extend the life of your ceramic coating, allowing you to enjoy its benefits for up to five years.

Specific Care for SiC Ceramic Coating

SiC ceramic coatings require specialized care due to their advanced chemical composition. I always use a pH-neutral car wash solution and a soft wash mitt or sponge to clean the surface. Harsh or abrasive cleaning agents should be avoided, as they can degrade the coating over time.

To maintain the coating’s high gloss and durability, I recommend using detailing products specifically formulated for ceramic coatings. These products enhance the hydrophobic properties and keep the surface looking pristine. Periodic inspections are also crucial. If I notice any damage, I address it promptly to prevent further issues.

For added protection, I use SiC-based boosters that chemically bond with the ceramic layer. These boosters provide an extra layer of defense against environmental factors like UV radiation and contaminants. Ceramic-friendly detail sprays are another excellent option for maintaining the coating’s hydrophobic properties and glossy finish.

お問い合わせ: SiC coatings are highly durable, but regular care ensures they perform at their best for years.

Specific Care for SiO2 Ceramic Coating

SiO2 ceramic coatings are easier to maintain but still require attention to detail. I wash the coated surface regularly with pH-neutral shampoos and a soft sponge or microfiber mitt. This prevents dirt and debris from scratching the surface. Harsh chemicals should be avoided, as they can weaken the coating’s bond.

To maintain the coating’s gloss and hydrophobic properties, I use ceramic-friendly detail sprays. These sprays rejuvenate the coating and keep the surface looking fresh. Since SiO2 coatings have a shorter lifespan, I inspect the surface more frequently for signs of wear. Touch-ups or reapplications may be necessary to ensure continued protection.

For vehicles with SiO2 coatings, I recommend applying a ceramic booster every few months. This helps restore the coating’s effectiveness and enhances its resistance to environmental factors. Parking in shaded areas also reduces exposure to UV rays, prolonging the coating’s lifespan.

チップ: Regular maintenance and periodic touch-ups can maximize the performance of SiO2 ceramic coatings, making them a cost-effective solution for vehicle protection.

Smicera Semiconductor (Ningbo Miami Advanced Material Technology Co., LTD) specializes in high-end advanced materials, including SiC and SiO2 ceramic coatings. Their expertise spans industries such as automotive, semiconductor, and new energy. With ISO 9001:2015 certification and a team of experienced professionals, Smicera delivers innovative solutions for vehicle protection. Their commitment to quality and cost-effective designs ensures reliable products trusted by customers worldwide.

Choosing between SiC and SiO2 ceramic coatings depends on understanding their distinct features. Here’s a quick comparison:

| Feature | SiC | シオ2 |

|---|---|---|

| Durability | Highly durable, lifetime guarantee | Less durable, better for short-term |

| Chemical Resistance | Exceptional resistance to harsh chemicals | Decent resistance, requires maintenance |

| Gloss and Aesthetics | Deeper, richer gloss | Good initial gloss, less long-lasting |

| Application Difficulty | Requires professional expertise | More accessible for DIY applications |

| コスト | Higher upfront cost, long-term savings | Lower initial cost, more frequent reapplications |

Selecting the right coating ensures your vehicle gets the protection it needs. Different coatings cater to unique needs, just as different cars suit various driving styles. Customizing your choice based on your vehicle’s features and environment prolongs its life and maintains its appearance.

チップ: Professional application ensures flawless results. Experts prepare surfaces correctly, apply coatings evenly, and maximize durability. DIY methods may save money initially but risk improper application, reducing effectiveness.

Smicera Semiconductor (Ningbo Miami Advanced Material Technology Co., LTD) specializes in high-end advanced materials, including SiC and SiO2 ceramic coatings. Their innovative solutions, backed by ISO 9001:2015 certification and a skilled R&D team, ensure reliable products for industries like automotive, semiconductor, and new energy. Trust Smicera for quality and expertise in ceramic coatings.

よくあるご質問

What is the main difference between SiC and SiO2 ceramic coatings?

SiC coatings offer superior durability, chemical resistance, and a deeper gloss. SiO2 coatings are more affordable and easier to apply but have a shorter lifespan. I recommend SiC for long-term protection and SiO2 for budget-conscious users.

Can I apply SiC or SiO2 coatings myself?

SiO2 coatings are DIY-friendly and straightforward to apply. SiC coatings require professional expertise due to their complex chemical composition and curing process. I always suggest consulting a professional for SiC applications to ensure optimal results.

How long do SiC and SiO2 coatings last?

SiC coatings can last over a decade with proper care. SiO2 coatings typically last 1-3 years, depending on maintenance. I find SiC coatings to be a better long-term investment for vehicle protection.

Are ceramic coatings completely scratch-proof?

No, ceramic coatings enhance scratch resistance but do not make surfaces entirely scratch-proof. I always advise careful maintenance and avoiding abrasive tools to preserve the coating’s integrity.

How do I maintain a ceramic coating?

Wash regularly with pH-neutral soap and avoid harsh chemicals. Use ceramic-friendly detail sprays or boosters every few months. I recommend inspecting the coating periodically to address any wear or damage promptly.

Which coating is better for extreme climates?

SiC coatings excel in extreme climates due to their exceptional chemical and thermal resistance. SiO2 coatings perform well in milder conditions. For vehicles exposed to harsh environments, I always recommend SiC coatings.

Does Smicera Semiconductor produce ceramic coatings?

Yes, Smicera Semiconductor specializes in advanced materials like SiC and SiO2 ceramic coatings. Their innovative solutions, backed by ISO 9001:2015 certification, ensure reliable products for industries such as automotive, semiconductor, and new energy.

Are ceramic coatings worth the cost?

Absolutely. Ceramic coatings protect your vehicle, enhance its appearance, and reduce maintenance efforts. While SiC coatings have a higher upfront cost, their durability and long-term benefits make them a worthwhile investment. SiO2 coatings offer a cost-effective alternative for short-term needs.

チップ: Choose a coating based on your vehicle’s usage, environment, and budget for the best results.