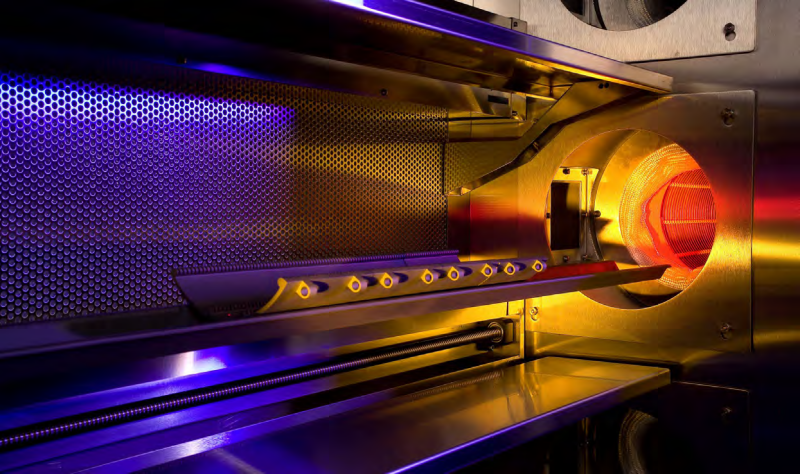

シスコ Cantileverのパドルはコーティングのモノクリスタルおよび多結晶性のケイ素のウエファーのための光起電の企業の拡散のコーティングの炉で使用されます。 高温・腐食性に優れ、長寿命を実現.

SiCカンチレバーパドルは高温拡散のコーティングの炉の管にケイ素のウエファーを運ぶSiCのボート/quartzのボートを提供します.

当社のSiCカンチレバーパドルの長さは、1,500〜3500 mmの範囲です。 SiC Cantileverのかい次元は顧客の指定に従ってなされるtailorである場合もあります.

| 再結晶化炭化ケイ素の物理的性質 | |

|

プロパティ |

典型的な価値 |

|

働く温度(°C) |

1600°C (酸素と)、1700°C (減少の環境) |

|

SiC コンテンツ |

> 99.96% |

|

無料の Si コンテンツ |

< 0.1% |

|

バルク密度 |

2.60-2.70 g/cm3 |

|

Apparent 気孔率 |

< 16% |

|

圧縮強度 |

> 600MPa |

|

冷たい曲げ強度 |

80-90 MPa (20°C) |

|

ホット曲げ強度 |

90-100 MPa (1400°C) |

|

熱膨張@1500°C |

4.70 10-6/°Cの |

|

熱伝導性@1200°C |

23 W/m・K |

|

弾性率 |

240 GPaの |

|

Thermal shock resistance |

非常に良い |

セミセラセミコンダクターは、2つの研究センターと3つの生産拠点で研究開発と生産を統合し、50の生産ラインと200人以上の従業員をサポートしています。

著作権©寧波マイアミ先端材料技術有限公司

著作権 © 2024.無断複写・転載を禁じます。