![]()

調達するとき silicon carbide coated susceptors、私は常に彼らの信頼性と品質で知られているサプライヤーを優先します。 モルガンの先端材料および東海カーボンCo.株式会社のような企業は特に実物で彼らの高度材料および革新的な解決と企業を、導きます SiCコーティング. . ここでは、いくつかを見てみましょう siCコーティングスセプターのトップサプライヤー:

| 会社概要 | 説明 |

|---|---|

| モーガン先進材料 | 先端材料の一流の製造者. |

| 東海カーボン株式会社. | カーボン製品の主要なプレーヤー. |

| SGLカーボンSE | 高性能材料の知識. |

| メルセングループ | 電気および熱解決に焦点を合わせて下さい. |

右の製造者を選ぶことは費用効果が大きいことを保障します。 炭化ケイ素によって塗られる感受性 長続きは、高温でよりよい実行し、より少ない維持を要求します. . 耐久性と効率性を要求する業界にスマートな投資をします.

要点

- Morgan Advanced MaterialsやTokai Carbonなどの信頼できるサプライヤーを選ぶ。 彼らは良い提供します SiCコーティングされた感受性器.

- ISO 9001のような認証を点検し、品質と信頼を確認します.

- SiCコーティングされた感受性器が熱および化学薬品をよく扱うかどうかテストして下さい。 これは、熱い条件でより良い仕事をするのに役立ちます.

- Alibaba や Thomasnet などのウェブサイトを使用して、 信頼できる売り手. . 製品の比較.

- 長期貯蓄について考えてみると、価格だけではありません。 耐久の感受性は修理のお金を節約します.

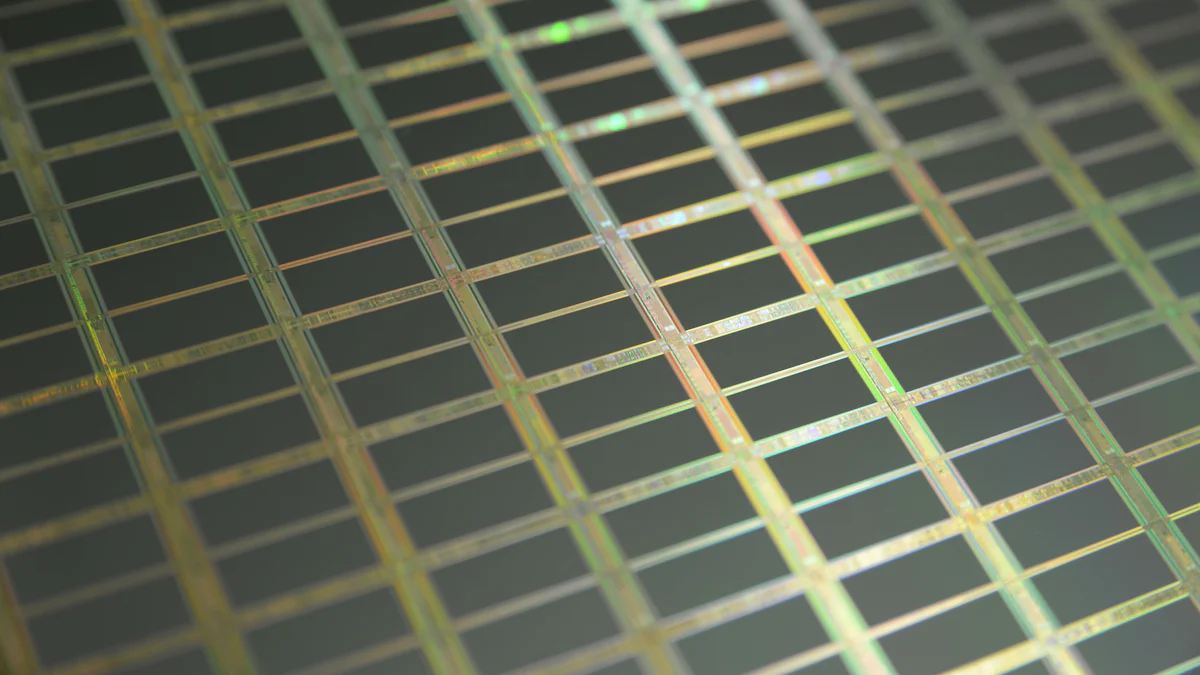

SiC-Coated Susceptorsの理解

SiC-Coated Susceptorsとは何ですか?

Definition and Composition

SiC-coated susceptors について考えると、高温工業プロセスの重要なコンポーネントとして見られます。 これらの受容体は、通常、炭化ケイ素(SiC)でコーティングされるグラファイトから作られています。 SiC層は、熱安定性と化学的安定性を兼ね備えたサスペンサーの性能を高めています。 この材料の組み合わせは、感受性が構造的完全性を維持しながら極端な条件に耐えることができることを保証します.

主要な物質的な特性

SiC-coatedの感受性器の独特な特性はさまざまな企業でそれらを必要とします。 スタンドアウト機能は次のとおりです

- 優れた熱伝導性: : : フィルム蒸着などのプロセスに重要な熱分布が確保されます.

- 高温抵抗: SiCコーティングされた感受性は温度に耐えることができます up to 1600°C 劣化なし.

- 化学抵抗: : : 酸、アルカリ、有機溶剤に抵抗し、過酷な環境にも適しています.

- Wear resistance: : : SiCコーティングは、高摩耗用途でも耐久性を提供します.

- 機械的強度: : : 堅牢性と強度は、要求の厳しい作業のために信頼できるものにします.

これらの特性により、SiC-coatedスセプターは、他の材料が失敗する可能性があるアプリケーションでExcel化することができます.

なぜ炭化ケイ素を使用するか?

SusceptorアプリケーションにおけるSiCの利点

シリコンカーバイドは、極端な条件下で一貫した性能を提供する能力のために際立っています。 熱伝導性が確保できるかを見てきました uniform heat distribution金属有機化学蒸気蒸着(MOCVD)のようなプロセスの精密な結果を達成するために重要である。 その化学的安定性は、半導体製造の過酷な環境でも劣化を防ぎます.

また、SiCコーティングスセプターは、単結晶基材の支持と加熱において重要な役割を果たしています。 これにより、熱安定性と均一性が確保され、エピタキシャル材料の成長の質に直接影響します。 SiCのコーティングはまた提供します 耐食性 そして熱衝撃の抵抗は、高温適用のためにそれを理想的にします.

熱安定性および耐久性

グラファイトやモリブデンなどの他の材料と比較して、炭化ケイ素は比類のない熱安定性を提供します。 極端な熱の下でも構造的な整合性を維持します。, 私は一貫した性能を必要とするアプリケーションのためにそれを好む理由です。. グラファイトは熱管理で優れていますが、SiCの耐久性と化学的安定性の組み合わせにより、より優れた支持者の選択が可能になります.

SiCコーティングされた感受性器を使用することによって、企業はよりよい効率、より長い装置の生命および良質の結果を達成できます。 これにより、あらゆる高温用途にスマートな投資が可能になります.

SiCコーティングされたスセプターのソースの場所

トップサプライヤーとメーカー

大手グローバルサプライヤー

調達するとき SiC coated susceptors、私は常にトップグローバルサプライヤーを探索することによって開始します。 東洋タンソ株式会社、SGLカーボンSE、東海カーボン株式会社などの企業は、その専門知識と革新のために際立っています. 強みの迅速な比較はこちら:

| 会社概要 | 分散機能 |

|---|---|

| 東洋タンソ株式会社. | 高品質のグラファイト製品と高度なコーティング技術、半導体および電子機器業界における強い存在. |

| SGLカーボンSE | SiCコーティングされたグラファイト製品の広い範囲;持続可能性と技術の進歩へのコミットメント. |

| 東海カーボン株式会社. | 高性能カーボンおよびグラファイト材料を専門にして下さい;半導体および電子工学の企業に焦点を合わせて下さい. |

これらの会社は高温適用の要求に応じる信頼できるプロダクトを渡すための評判を造りました.

信頼できる製造業者の特徴

信頼性を確保するために、特定の基準に基づいてメーカーを常に評価しています。 私が探している主な機能は次のとおりです

- 品質基準に遵守を発揮するISO 9001などの認証.

- 強い評判で MOCVD技術、重要な適用のためのカスタマイズされた解決を保障します.

- 製品が要求された仕様を満たしていることを確認するためのテスト機能.

- 経理性のための製品の旅の追跡を可能にするトレーサビリティシステム.

これらの要因は、一貫して高品質のSiCコーティングスセプターを提供するメーカーを識別するのに役立ちます.

SiCコーティングスセプター用オンラインマーケットプレイス

信頼できるプラットフォーム

オンライン市場は、SiCコーティングされたスセプターをソースするのに便利な方法を提供します。 Alibaba、Thomasnet、GlobalSpecなどのプラットフォームは、バイヤーを検証サプライヤーに接続します。 彼らは詳細なサプライヤープロファイル、顧客のレビュー、製品仕様を提供するので、私はこれらのプラットフォームを好む.

売り手を評価するためのヒント

売り手をオンラインで評価するときは、信頼性と製品品質に重点を置いています。 ISO 9001のような証明は製造者が厳密な品質管理の練習に続くことを示します。 私はまた、実際の生産条件下でsusceptorのパフォーマンスを評価するためにサンプル要求のテストを要求します。 売り手との強い関係を築くことは、多くの場合、バルク注文や延長保証の割引など、より良い条件につながります.

主な考慮事項 調達するとき

品質認証と規格

品質認証 siCコーティングされた感受性を調達するときは不可欠です。 1人の専門家が指摘したように、,

「SiC-coatedのグラファイトの感受性の熱安定性そして均等性はそれらにMOCVD装置の中心の部品を作るエピタキシャル材料の成長の質のために重大です。 ツイート

以下の認証を常にチェックします

- 一貫した製品品質のためのISO 9001.

- 熱安定性、耐薬品性、寸法精度のためのIEC規格.

- サプライヤーの信頼性を確かめる証明の文書.

価格と配送オプション

仕入業者間での価格設定と配送オプションは大きく異なります。 私は明確な船積みの選択、保証された郵送物および通関手続きを提供する製造者を捜します。 バルク注文は、適切な包装が適切な状態に着きますが、一口あたりのコストを削減します。 グローバルな物流経験のあるサプライヤーとのコラボレーションにより、遅延を最小限に抑え、スムーズな配送を実現します.

SiCコーティングスセプターの適用

産業用途

半導体製造

私は見た SiC-coatedスセプターは半導体製造において重要な役割を果たしています. . これらは、化学蒸気蒸着(CVD)や金属有機化学蒸気蒸着(MOCVD)などのプロセスで不可欠です。 ガリウム窒化物(GaN)などの材料のエピタキシャル成長中のこれらの受容体支持および熱基質。 均一な熱伝導性は一貫した結果を保障しますが、高温抵抗は極端な条件下の性能を維持します。 SiCコーティングの化学的安定性は腐食を防ぎ、過酷な環境にも最適です.

太陽光発電 生産工程

太陽電池製造では、SiCコーティングされた感受性は信頼性および効率を提供します。 それらは良質の太陽電池を作り出すために重要な精密な温度制御を保障します。 耐久性がダウンタイムを削減し、大規模生産にコスト効果の高い選択肢を出すことに気付きました。 高温に耐え、化学劣化に抵抗する能力は、この業界で不可欠です.

航空宇宙・その他産業

航空宇宙部門は、SiCコーティングされた感受性器の機械的強度と熱安定性から恩恵を受けています。 これらの特性は、タービン部品や熱シールドなどの高性能な用途に適しています。 自動車や電子機器などの他の産業は、これらの感受性器を使用して、プロセスの耐久性と効率性を高めます.

Technological Advancements

新興用途

SiC-coated susceptors は、業界がより精密で効率性を要求する新しいアプリケーションを見つけることを観察しました. SiCコーティング技術の継続的な進歩 パフォーマンスを改善しています。 例えば、, 蒸着技術の革新 より均一なコーティングを可能にし、欠陥を減らし、信頼性を高めます。 航空宇宙や自動車などの産業は、重要なコンポーネントの長寿を改善するために、これらのコーティングを採用しています.

SiCコーティング技術の革新

SiCコーティング技術の最近の発展は、業界を変革しています。 高度な化学蒸気蒸着(CVD)方式により、高純度・均一性を実現。 プラズマ強化CVDとハイブリッド技術により、妥協することなく、堆積率を高速化できます。 特定の適用のためのコーティングのカスタム化は最高の効率を保障し、材料の無駄を減らします。 これらのイノベーションは、SiCコーティングされたスセプターの進化を促進し、より汎用性と費用対効果の高いものにしています.

| Technological Advancements | 説明 |

|---|---|

| 熱安定性 | SiC-coatedの感受性は従来の材料と比較して優秀な熱安定性を提供します. |

| Chemical Resistance | 耐薬品性の向上により、半導体プロセスの耐久性が向上します. |

| Mechanical Strength | より大きい機械強さはより高いプロセス効率および収穫に貢献します. |

これらの進歩は、業界全体のSiCコーティングされた受容体の重要性を強調しています.

適切な要因に焦点を合わせると、SiC-coated susceptors を調達するのは簡単です。 特定のリアクターのニーズを満たすスセプターをカスタマイズすることで、パフォーマンスを向上させ、互換性を保証します。 認定資格に基づいてサプライヤーを常に評価しています ISO 9001 業界での評判。 信頼できる製造者は生産の危険を減らす一貫した質、時機を得たサポートおよびカスタマイズされた解決を、提供します。 サンプルテストは、大量注文にコミットする前に性能を検証します.

長期的価値は初期費用以上の問題です。 輸送物流を理解しながら、より良い条件を確保できる強力な交渉スキルは、納期とコストを管理するのに役立ちます。 これらの手順を優先することで、ニーズに最適なサプライヤーを安心して選択できます.

よくあるご質問

SiC-coated susceptors を使用する業界は?

半導体製造、太陽光発電製造、航空宇宙産業が大きく依存していることに気づきました SiCコーティングされた感受性器. . これらの業界は、SiCコーティングスセプターが提供する高熱安定性と耐久性を要求します.

SiC-coatedスセプターの品質を評価する方法は?

ISO 9001、IEC規格などの認証を取得しています。 実際の生産条件の下のサンプルのテストは性能を確かめるのを助けます。 信頼できる製造者はまた詳しい文書およびトレーサビリティを提供します.

SiCコーティングされた感受性器はカスタマイズ可能ですか?

はい、多くのメーカーは提供しています カスタマイズ. . 特定の原子炉の設計かプロセス条件に製造者のtailorのsusceptorsを見ました。 これは、互換性を確保し、パフォーマンスを向上させます.

SiCコーティングされた感受性器は費用効果が大きいですか?

耐久性と耐摩耗性でメンテナンスコストを削減 長年にわたる寿命と一貫した性能で、高温用途向けのスマート投資を実現しました.

SiC-coated susceptorsをオンラインで供給できますか?

絶対に! Alibaba や Thomasnet などのプラットフォームは、検証済みサプライヤーとバイヤーを接続します。 購入前に質を保障するために顧客からのフィードバックの要求そしてサンプルを点検することを推薦します.