Energy storage systems rely on advanced materials to improve efficiency and durability. Vitreous coated graphite has emerged as a transformative material in this field. Its unique properties, such as enhanced conductivity and resistance to environmental degradation, make it a game-changer. Recent advancements in carbide coatings and sic coating technologies have further expanded its potential applications. Researchers predict that 2025 will mark a turning point for coated graphite, with innovations driving scalability and cost-effectiveness. These breakthroughs, including pg coated graphite, promise to revolutionize energy storage while supporting global sustainability goals.

Key Takeaways

- Glass-like coated graphite makes energy storage better and lasts longer.

- The coating keeps graphite safe from damage, so it lasts more.

- New coating methods make stronger bonds, helping it work under pressure.

- Better factory methods make it easier to produce this coated graphite.

- It now costs less to make without losing quality, helping more people use it.

- This coated graphite is important for batteries and supercapacitors, storing more energy and lasting longer.

- It works well in tough conditions, great for renewable energy and big storage systems.

- Scientists and companies work together to turn ideas into real-world uses faster.

Understanding Vitreous Coated Graphite

Composition and Structure

The science behind vitreous coatings.

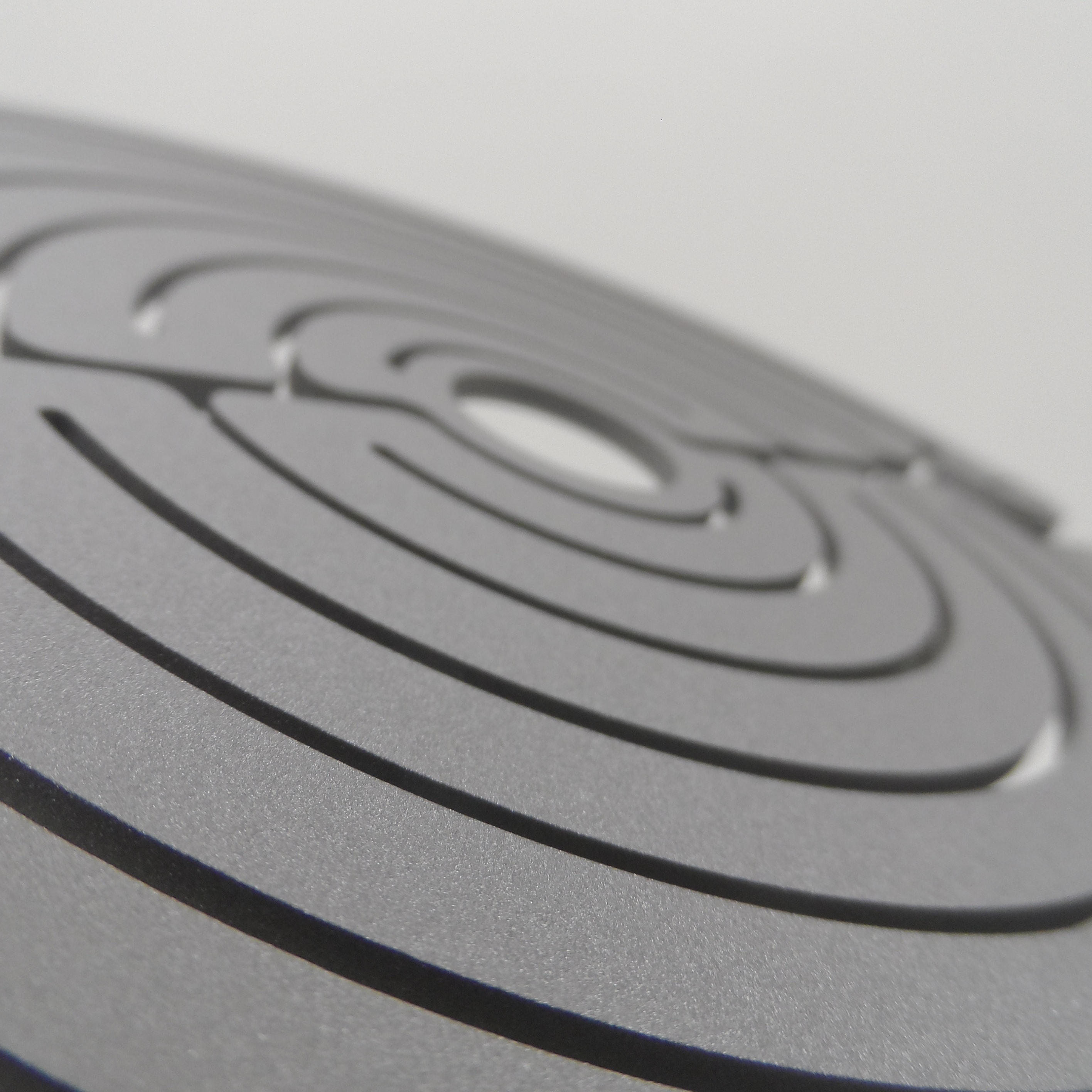

Vitreous coatings are thin, glass-like layers applied to materials to enhance their properties. These coatings are typically made from inorganic compounds that form a non-crystalline, amorphous structure. Scientists design these coatings to improve the performance of the underlying material. In the case of vitreous coated graphite, the coating acts as a protective barrier while also enhancing conductivity. The non-crystalline nature of the coating allows it to resist cracking and maintain its integrity under stress. This makes it an ideal choice for energy storage applications.

The process of creating vitreous coatings involves high-temperature treatments. These treatments ensure that the coating adheres strongly to the graphite surface. Researchers have developed advanced techniques to control the thickness and uniformity of the coating. This precision ensures consistent performance across different applications. The science behind these coatings continues to evolve, with ongoing research focusing on improving their durability and efficiency.

Interaction between vitreous coatings and graphite.

Graphite serves as an excellent base material due to its unique properties. It is lightweight, highly conductive, and chemically stable. When combined with a vitreous coating, these properties are further enhanced. The coating forms a strong bond with the graphite surface, creating a composite material with superior performance.

The interaction between the coating and graphite is crucial for energy storage. The coating protects the graphite from environmental factors like oxidation and corrosion. At the same time, it allows for efficient electron transport, which is essential for storing and discharging energy. This synergy between the coating and graphite makes vitreous coated graphite a key material in modern energy systems.

Unique Properties

Enhanced conductivity and energy efficiency.

Vitreous coated graphite exhibits exceptional electrical conductivity. The coating minimizes energy losses during storage and discharge, making the material highly efficient. This property is particularly important for applications like batteries and supercapacitors, where energy efficiency is critical.

Thermal and chemical stability.

The material demonstrates remarkable stability under extreme conditions. It can withstand high temperatures without degrading, making it suitable for demanding environments. Additionally, the coating resists chemical reactions, ensuring long-term performance even in harsh conditions.

Resistance to environmental degradation.

Environmental factors like moisture, oxygen, and pollutants can degrade many materials over time. However, vitreous coated graphite resists these challenges effectively. The coating acts as a shield, protecting the graphite from oxidation and corrosion. This resistance extends the lifespan of the material, reducing the need for frequent replacements.

Note: These unique properties make vitreous coated graphite a versatile material for energy storage. Its combination of conductivity, stability, and durability sets it apart from other materials.

Key Advancements in 2025

Improved Durability

Innovations in coating techniques for longer-lasting materials.

Researchers have introduced advanced coating methods to improve the durability of vitreous coated graphite. These techniques focus on creating stronger bonds between the vitreous layer and the graphite substrate. By refining the application process, scientists have achieved coatings that resist cracking and peeling over time. High-temperature treatments and precision layering ensure the coating remains intact even under prolonged use. These innovations extend the lifespan of the material, making it more reliable for energy storage systems.

Enhanced performance in high-stress environments.

Energy storage systems often operate in challenging conditions. Vitreous coated graphite now demonstrates improved performance in high-stress environments. The material withstands mechanical stress, such as repeated charge and discharge cycles, without losing efficiency. It also maintains its structural integrity under extreme pressures. These advancements make it suitable for applications requiring consistent performance, such as grid-level energy storage and high-capacity batteries.

Enhanced Conductivity

Advances in electron transport mechanisms.

Recent breakthroughs have optimized the electron transport mechanisms within vitreous coated graphite. Scientists have engineered the coating to reduce resistance, allowing electrons to move more freely. This improvement enhances the material’s conductivity, which is critical for efficient energy transfer. By fine-tuning the coating’s composition, researchers have created a material that supports faster and more reliable energy storage.

Reduction in energy losses during storage and discharge.

Energy losses during storage and discharge have been a persistent challenge. Vitreous coated graphite now addresses this issue through its improved design. The coating minimizes resistance at the interface between the graphite and the vitreous layer. This reduction in resistance ensures that more energy is retained during storage and efficiently released when needed. These advancements contribute to higher energy efficiency in modern storage systems.

Environmental Resistance

Performance in extreme conditions.

Vitreous coated graphite exhibits remarkable resilience in extreme conditions. The material performs reliably in environments with high temperatures, intense pressures, or fluctuating humidity levels. This capability makes it a preferred choice for energy storage systems deployed in harsh climates or industrial settings. Its ability to maintain functionality under such conditions ensures consistent energy supply.

Resistance to oxidation and corrosion.

Oxidation and corrosion can significantly degrade materials over time. The vitreous coating acts as a protective barrier, shielding the graphite from these harmful processes. This resistance extends the material’s operational life and reduces maintenance requirements. By preventing degradation, vitreous coated graphite remains a durable and cost-effective solution for energy storage applications.

Scalability and Cost-Effectiveness

New manufacturing processes for mass production.

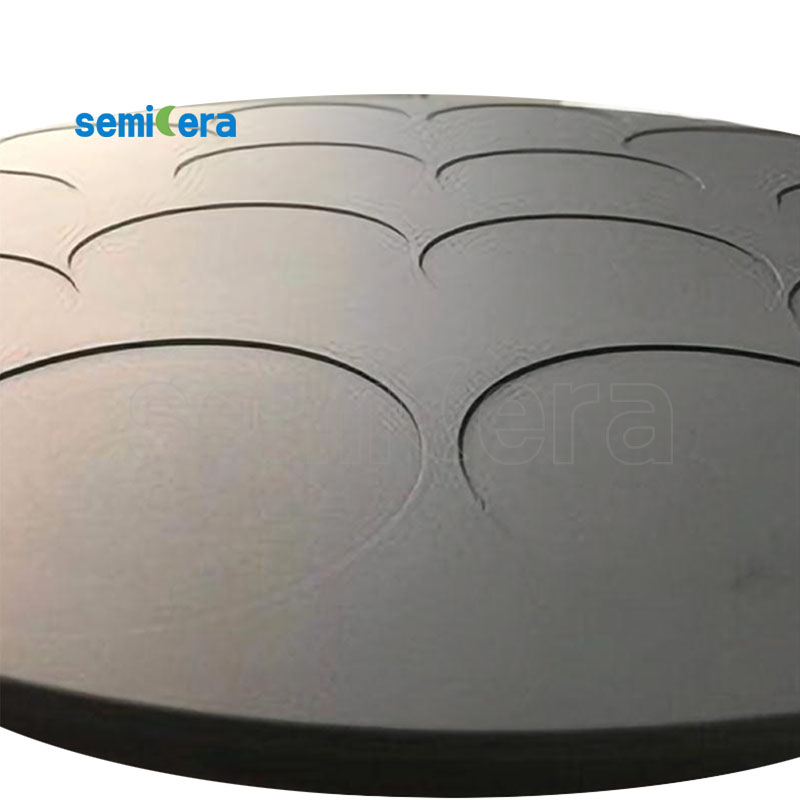

Scaling up the production of vitreous coated graphite has been a significant focus for researchers and manufacturers. Recent advancements in manufacturing techniques have made it possible to produce this material on a larger scale without sacrificing quality. One of the most notable innovations involves automated coating systems. These systems apply the vitreous layer with precision, ensuring uniformity across large batches of graphite substrates. This level of consistency is crucial for maintaining the material’s performance in energy storage applications.

Another breakthrough involves the use of high-throughput processing methods. These methods allow manufacturers to coat multiple graphite components simultaneously, significantly reducing production time. For example, roll-to-roll processing has emerged as a game-changing technique. It enables continuous coating of graphite sheets, making the process faster and more efficient. By adopting these methods, manufacturers can meet the growing demand for vitreous coated graphite in industries like renewable energy and electric vehicles.

Tip: High-throughput methods not only save time but also reduce waste, making the production process more sustainable.

Lower production costs without compromising quality.

Reducing production costs remains a priority for the widespread adoption of vitreous coated graphite. Researchers have developed cost-effective alternatives to traditional coating materials. These alternatives maintain the desired properties of the vitreous layer while lowering raw material expenses. For instance, some manufacturers now use recycled or locally sourced compounds to create the coating. This approach minimizes costs and supports environmental sustainability.

Energy-efficient manufacturing processes also play a role in cost reduction. Techniques like low-temperature curing and optimized thermal treatments consume less energy, lowering operational expenses. Additionally, advancements in equipment design have reduced maintenance costs, further improving the economic feasibility of mass production.

Collaboration between academia and industry has accelerated these cost-saving innovations. Research institutions provide insights into material science, while manufacturers focus on practical implementation. This partnership ensures that new methods are both scientifically sound and commercially viable.

Note: Lowering costs does not mean compromising on quality. Rigorous testing ensures that every batch of vitreous coated graphite meets industry standards for durability and performance.

By combining scalable production methods with cost-effective strategies, the industry is paving the way for broader adoption of this transformative material. These advancements make it possible to integrate vitreous coated graphite into a wide range of energy storage systems, supporting the transition to a more sustainable future.

Applications in Energy Storage

Batteries

Role in lithium-ion and solid-state batteries.

Batteries play a critical role in modern energy storage systems. Lithium-ion and solid-state batteries, in particular, benefit significantly from the integration of vitreous coated graphite. This material enhances the performance of battery electrodes by improving conductivity and protecting against environmental degradation. In lithium-ion batteries, it facilitates faster ion movement, which boosts charging speeds. Solid-state batteries, known for their safety and energy density, also gain improved stability and efficiency through this advanced material. These enhancements make batteries more reliable and efficient for applications like electric vehicles and portable electronics.

Increased energy density and charge cycles.

Energy density and charge cycles are key metrics for evaluating battery performance. Vitreous coated graphite contributes to higher energy density by enabling more efficient energy storage within the battery. It also extends the number of charge and discharge cycles a battery can endure without significant performance loss. This durability reduces the need for frequent replacements, lowering costs and environmental impact. These improvements position batteries with vitreous coated graphite as a cornerstone of next-generation energy storage solutions.

Supercapacitors

Enhanced charge/discharge rates.

Supercapacitors excel in applications requiring rapid energy transfer. Vitreous coated graphite enhances their performance by increasing conductivity and reducing internal resistance. These improvements allow supercapacitors to achieve faster charge and discharge rates. This capability is essential for technologies like regenerative braking systems in electric vehicles, where quick energy recovery is crucial. The material’s stability ensures consistent performance even under high-stress conditions, making it a valuable component in supercapacitor design.

Applications in renewable energy systems.

Renewable energy systems often face challenges related to energy intermittency. Supercapacitors equipped with vitreous coated graphite help address this issue by providing rapid energy storage and release. For example, they can store excess energy generated by solar panels during peak sunlight hours and discharge it when demand increases. This functionality supports the integration of renewable energy into the grid, promoting a more sustainable energy landscape.

Grid-Level Energy Storage

Stabilizing renewable energy sources.

Grid-level energy storage systems must handle large-scale energy fluctuations. Vitreous coated graphite enhances the efficiency and reliability of these systems. By improving conductivity and durability, it ensures stable energy transfer and storage. This stability is crucial for balancing the variable output of renewable energy sources like wind and solar power. As a result, it helps maintain a consistent energy supply to the grid, even during periods of low generation.

Long-term storage solutions for smart grids.

Smart grids require advanced materials to meet the demands of long-term energy storage. Vitreous coated graphite offers the necessary durability and efficiency for these applications. Its resistance to environmental degradation ensures reliable performance over extended periods. This capability supports the development of smart grids that can store energy for days or weeks, enabling better management of renewable energy resources. By integrating this material, grid-level storage systems become more robust and cost-effective, paving the way for a sustainable energy future.

Challenges and Limitations

Material Stability

Issues with long-term performance.

Vitreous coated graphite faces challenges in maintaining performance over extended periods. Prolonged use in energy storage systems can lead to gradual wear and tear. This degradation often results from repeated charge and discharge cycles, which stress the material. Over time, the vitreous coating may lose its protective properties, exposing the graphite to environmental factors. This exposure can reduce conductivity and efficiency, impacting the overall performance of energy storage devices.

Note: Researchers are actively exploring ways to enhance the longevity of vitreous coatings. Innovations in material composition and application techniques could address these issues.

Potential degradation under high stress.

High-stress environments, such as extreme temperatures or mechanical pressures, can accelerate the degradation of vitreous coated graphite. The material may experience micro-cracks or delamination under these conditions. These defects compromise the coating’s ability to protect the graphite, leading to reduced durability. For instance, in grid-level energy storage, the material must endure significant stress, which can shorten its lifespan.

To mitigate these challenges, scientists are investigating advanced coating methods. These methods aim to improve the material’s resilience under stress, ensuring consistent performance in demanding applications.

Scalability

Challenges in large-scale production.

Scaling up the production of vitreous coated graphite presents significant hurdles. The precision required for applying the vitreous coating makes the process complex and time-consuming. Manufacturers must ensure uniformity and quality across large batches, which can be difficult to achieve. Additionally, the high-temperature treatments needed for coating application increase production costs and energy consumption.

Tip: Automation and high-throughput processing methods, such as roll-to-roll systems, offer potential solutions. These technologies streamline production and improve efficiency.

Balancing cost and performance.

Producing vitreous coated graphite at a competitive cost without sacrificing quality remains a challenge. High-quality coatings require expensive raw materials and advanced equipment. Reducing costs often risks compromising the material’s performance, which is unacceptable for critical energy storage applications. Striking the right balance between affordability and functionality is essential for widespread adoption.

Collaboration between researchers and manufacturers plays a key role in overcoming this limitation. By sharing knowledge and resources, they can develop cost-effective solutions that maintain high performance.

Environmental Concerns

Recycling and disposal of vitreous coated graphite.

The disposal of vitreous coated graphite raises environmental concerns. The material’s durability, while beneficial for energy storage, complicates recycling efforts. Separating the vitreous coating from the graphite substrate requires specialized processes, which are not yet widely available. Improper disposal could lead to environmental pollution, undermining the sustainability goals of energy storage systems.

Callout: Developing efficient recycling methods is crucial for minimizing the environmental impact of vitreous coated graphite. Research into eco-friendly separation techniques is ongoing.

Addressing the carbon footprint of production.

The production of vitreous coated graphite involves energy-intensive processes, contributing to its carbon footprint. High-temperature treatments and the use of non-renewable raw materials add to the environmental impact. Reducing this footprint is essential for aligning the material with global sustainability objectives.

Manufacturers are exploring greener alternatives, such as renewable energy sources for production and recycled materials for coatings. These efforts aim to make vitreous coated graphite a more environmentally friendly option for energy storage.

Reminder: Sustainability in production and disposal will determine the long-term viability of vitreous coated graphite in energy storage systems.

Future Directions and Research

Emerging Coating Techniques

Nanotechnology-based approaches

Nanotechnology offers exciting possibilities for improving vitreous coated graphite. Researchers are exploring nanoscale coatings that enhance the material’s conductivity and durability. These coatings create a more uniform layer, reducing imperfections that can lead to degradation. By manipulating materials at the atomic level, scientists can achieve coatings with superior performance.

One promising approach involves embedding nanoparticles into the vitreous layer. These particles improve electron transport, making energy storage systems more efficient. Another method uses nanostructured surfaces to increase the coating’s adhesion to graphite. This innovation reduces the risk of peeling or cracking, even under high stress.

Tip: Nanotechnology-based coatings could revolutionize energy storage by offering unmatched precision and performance.

Hybrid materials for enhanced performance

Hybrid materials combine the strengths of different substances to create a superior coating. For vitreous coated graphite, researchers are blending inorganic compounds with polymers or ceramics. These combinations enhance the coating’s flexibility, making it more resistant to mechanical stress.

Hybrid coatings also improve thermal stability. For example, ceramic-polymer blends can withstand extreme temperatures without degrading. This makes them ideal for applications in harsh environments. By integrating hybrid materials, scientists aim to create coatings that balance durability, conductivity, and cost-effectiveness.

Integration with Renewable Energy Systems

Role in solar and wind energy storage

Renewable energy sources like solar and wind require efficient storage solutions. Vitreous coated graphite plays a critical role in these systems. Its high conductivity ensures rapid energy transfer, while its durability supports long-term use.

In solar energy systems, the material stores excess energy generated during peak sunlight hours. For wind energy, it stabilizes output by storing energy during high wind periods and releasing it when needed. These capabilities make it an essential component of renewable energy infrastructure.

Supporting the transition to a carbon-neutral future

The global push for carbon neutrality relies on advanced energy storage technologies. Vitreous coated graphite supports this transition by improving the efficiency and reliability of renewable energy systems. Its resistance to environmental degradation reduces waste, aligning with sustainability goals.

By enabling better energy storage, this material helps reduce dependence on fossil fuels. It also supports the integration of renewable energy into smart grids, paving the way for a cleaner, greener future.

Callout: Advanced materials like vitreous coated graphite are key to achieving a carbon-neutral world.

Collaboration Between Academia and Industry

Accelerating innovation through partnerships

Collaboration between academic researchers and industry leaders accelerates innovation. Universities provide cutting-edge research on materials science, while companies focus on practical applications. This partnership ensures that new discoveries quickly transition from the lab to the market.

Joint research initiatives have already led to breakthroughs in coating techniques and manufacturing processes. By pooling resources and expertise, academia and industry can overcome challenges like scalability and cost.

Bridging the gap between research and commercialization

The gap between research and commercialization often delays the adoption of new technologies. Collaborative efforts aim to bridge this divide. Industry partners test academic innovations in real-world conditions, providing valuable feedback.

These partnerships also focus on training the next generation of scientists and engineers. By involving students in research projects, they prepare them for careers in advanced materials development. This ensures a steady flow of talent to drive future advancements.

Reminder: Strong collaboration between academia and industry is essential for turning innovative ideas into practical solutions.

Vitreous coated graphite has redefined the possibilities of energy storage. Its advancements in conductivity, durability, and environmental resistance have positioned it as a cornerstone of modern energy systems. These breakthroughs promise to enhance the efficiency of batteries, supercapacitors, and grid-level storage. By addressing challenges like scalability and sustainability, this material supports the global shift toward renewable energy. Future research and collaboration will likely unlock even greater potential, paving the way for a cleaner and more energy-efficient world.

FAQ

What is vitreous coated graphite?

Vitreous coated graphite is a composite material. It combines graphite’s conductivity with a glass-like coating for protection. This coating enhances durability, conductivity, and resistance to environmental factors, making it ideal for energy storage applications.

How does vitreous coated graphite improve energy storage?

The material improves energy storage by reducing energy losses and increasing efficiency. Its high conductivity supports faster energy transfer. The coating protects against oxidation and corrosion, ensuring long-term performance in batteries, supercapacitors, and grid-level systems.

Why is 2025 significant for this technology?

Researchers predict major advancements in 2025. These include improved durability, enhanced conductivity, and scalable production methods. These innovations will make vitreous coated graphite more accessible and cost-effective for widespread energy storage applications.

What are the environmental benefits of this material?

Vitreous coated graphite supports sustainability by extending the lifespan of energy storage systems. Its durability reduces waste. Researchers are also exploring eco-friendly production methods to lower its carbon footprint, aligning with global sustainability goals.

Can vitreous coated graphite be recycled?

Recycling vitreous coated graphite is challenging due to its durable coating. Specialized processes are required to separate the coating from the graphite. Researchers are developing efficient recycling methods to address this issue and minimize environmental impact.

What industries benefit most from this technology?

Industries like renewable energy, electric vehicles, and smart grids benefit significantly. Vitreous coated graphite enhances the performance of batteries and supercapacitors, supporting efficient energy storage and transfer in these sectors.

How does this material perform in extreme conditions?

The material demonstrates excellent thermal and chemical stability. It resists high temperatures, intense pressures, and environmental degradation. This makes it suitable for demanding applications, including industrial energy storage and renewable energy systems.

What challenges remain for vitreous coated graphite?

Challenges include scalability, cost reduction, and long-term material stability. Researchers are addressing these issues through advanced coating techniques, automated production methods, and innovations in material composition.

Tip: Continued research and collaboration between academia and industry will help overcome these challenges and unlock the full potential of this technology.