Carbon-carbon composites are advanced materials composed of carbon fibers embedded in a carbon matrix. These materials exhibit exceptional strength, lightweight properties, and resistance to extreme heat. Industries such as aerospace and automotive increasingly rely on them to meet regulatory demands for fuel efficiency and emission reduction. The global market for these composites is projected to grow significantly, driven by their diverse carbon carbon composites applications and unmatched performance.

The carbon composites market is expected to reach $8.79 billion by 2025, with aerospace and defense sectors leading the demand. Lightweight materials also play a crucial role in wind energy and electric vehicle advancements.

Carbon fiber carbon plate technology exemplifies the versatility of carbon carbon composites, making them indispensable in modern engineering.

Key Takeaways

- Carbon-carbon composites combine carbon fibers and a carbon matrix, offering exceptional strength, lightweight properties, and thermal stability, making them ideal for high-performance applications in aerospace and automotive industries.

- These composites are revolutionizing various sectors by providing solutions that enhance fuel efficiency and reduce emissions, with the market projected to reach $8.79 billion by 2025, driven by their diverse applications.

- Recent innovations in manufacturing, such as chemical recycling and nanotechnology, are improving the sustainability and performance of carbon-carbon composites, positioning them as key materials in advancing green energy and modern engineering.

Composition and Properties

What Are Carbon-Carbon Composites Made Of?

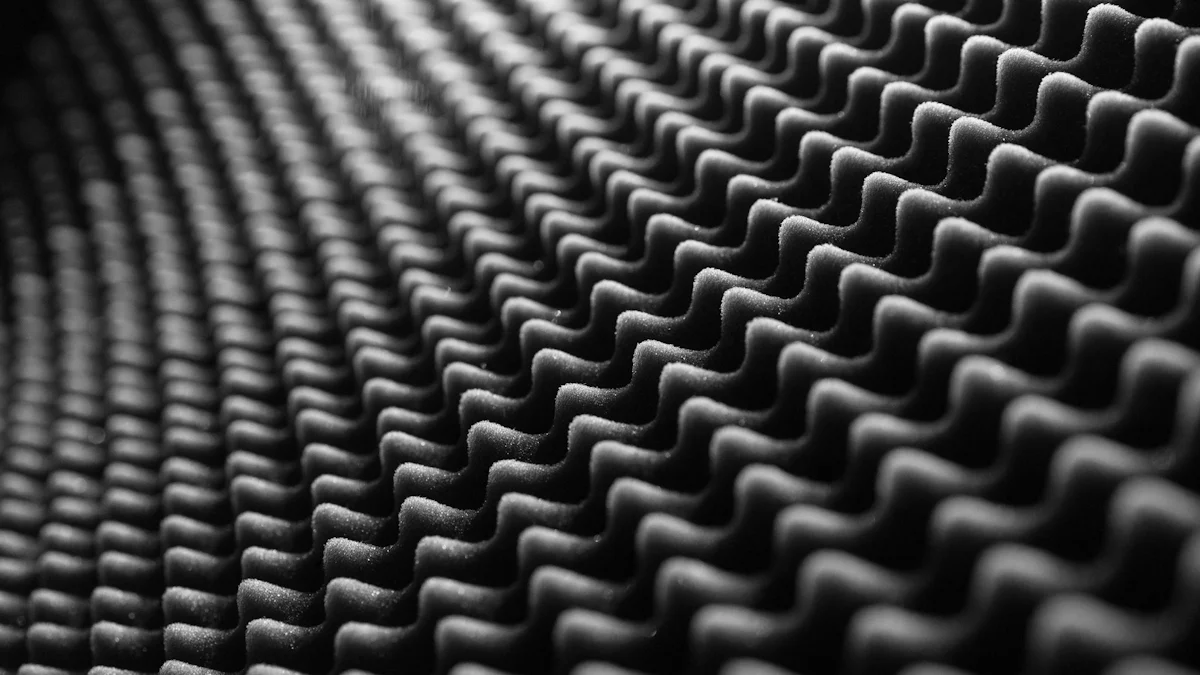

Carbon-carbon composites consist of two primary components: carbon fibers and a carbon matrix. Carbon fibers contribute exceptional strength and stiffness, while the carbon matrix provides thermal resistance and structural integrity. Together, these elements form a composite material capable of withstanding extreme conditions. The interaction between the fibers and the matrix ensures superior mechanical properties, making these composites ideal for high-performance applications.

Key Properties of Carbon-Carbon Composites

Carbon-carbon composites exhibit a unique combination of physical and chemical properties that set them apart from traditional materials. Key characteristics include:

- High tensile, flexural, and compressive strength.

- Exceptional thermal stability, maintaining structural integrity at temperatures exceeding 3000°C.

- Superior thermal conductivity, enabling efficient heat dissipation.

- Low coefficient of thermal expansion, which prevents deformation under heat.

- Outstanding wear resistance, ensuring durability in demanding environments.

These properties make carbon-carbon composites indispensable in industries like aerospace, where lightweight and high-performance materials are critical. For example, airplane braking systems and rocket nozzles often rely on these composites for their unmatched stability and strength.

Manufacturing Process of Carbon-Carbon Composites

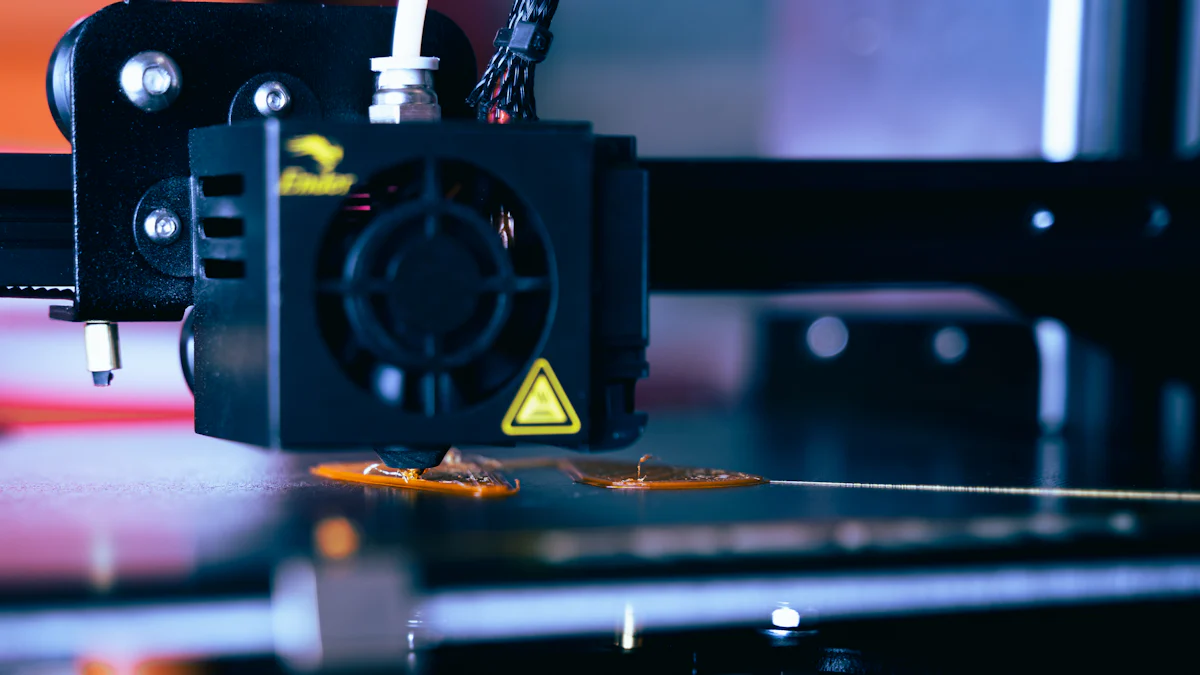

The production of carbon-carbon composites involves several advanced techniques, each tailored to enhance the material’s performance. Common methods include:

| Method | Description |

|---|---|

| Pre-densification | Fills gaps in fiber bundles and reduces large pores. |

| Impregnation and Pyrolysis | Cycles of impregnation and pyrolysis under moderate pressure. |

| Carbonization | Converts organic material into carbon. |

| Graphitization | Enhances the composite’s properties through high-temperature treatment. |

| Prepreg Lay-Up | Uses resin-wetted carbon fibers, partially cured, then fully cured under heat and pressure. |

These processes ensure the final product achieves the desired strength, thermal resistance, and dimensional stability. Manufacturers often use carbon fiber carbon plate technology during production to create lightweight yet robust components for various applications.

Applications Across Industries

Aerospace and Defense

Carbon-carbon composites play a critical role in aerospace and defense due to their ability to withstand extreme temperatures and mechanical stress. These materials are essential in high-performance components such as turbine engine leading edges, aircraft brake pads, and hypersonic vehicle nozzles. Their low density and high specific strength make them ideal for applications requiring lightweight yet durable materials.

Carbon composites are increasingly replacing traditional metal structures in aircraft. Their lightweight and stiff design enhances fuel efficiency and reduces overall weight.

In addition to aerospace, the defense sector benefits from these composites in ground defense systems, missile components, and military marine applications. From rotor blades in helicopters to interior airplane components, carbon-carbon composites ensure reliability and performance in demanding environments.

Automotive and Motorsports

The automotive and motorsports industries rely on carbon-carbon composites to enhance vehicle performance and safety. These materials are widely used in advanced braking systems, offering exceptional thermal stability and heat dissipation. High-speed racing vehicles benefit from their resistance to brake fade during prolonged use.

- Carbon-ceramic brakes, which incorporate carbon fibers, deliver superior stopping power.

- These brakes reduce unsprung weight compared to traditional steel brakes, improving handling and efficiency.

- The use of carbon-carbon composites ensures reliability and durability, critical for motorsports applications.

By integrating these materials, manufacturers achieve better braking performance and overall vehicle reliability.

Energy and Industrial Applications

Carbon-carbon composites revolutionize energy and industrial sectors by offering lightweight, durable, and efficient solutions. Their resistance to heat, chemicals, and corrosion makes them ideal for harsh environments.

Carbon composites represent a paradigm shift in engineering, enabling industries to meet modern challenges with innovative designs and materials.

Key advantages include:

- Versatile Design: Lightweight composites allow for intricate part designs.

- Enhanced Durability: Resistance to fatigue ensures long-lasting performance.

- Exceptional Stiffness: High strength-to-weight ratio supports heavy loads with minimal material.

These properties make carbon-carbon composites indispensable in applications such as photovoltaic systems, semiconductors, and new energy technologies.

Advantages and Challenges

Benefits Over Traditional Materials

Carbon-carbon composites outperform traditional materials like aluminum and steel in several key areas. Their strength and weight advantages make them indispensable in industries requiring high-performance materials. For instance:

- Carbon fiber offers 2 to 5 times more rigidity than aluminum and steel, depending on the fiber type.

- In components stressed along one plane, one-direction carbon fiber can be 5 to 10 times stiffer than steel or aluminum of the same weight.

These composites also exhibit exceptional thermal stability and conductivity, maintaining their structural integrity at extreme temperatures. Their superior mechanical properties, including tensile and flexural strength, make them ideal for aerospace applications. The use of carbon fiber carbon plate technology further enhances their versatility, enabling lightweight yet robust designs.

Challenges in Production and Cost

Despite their advantages, carbon-carbon composites face significant production challenges:

- High production costs arise from expensive raw materials and complex manufacturing processes.

- Limited awareness among end-users about their benefits and applications slows adoption rates.

- Supply chain vulnerabilities, including reliance on specialized suppliers, lead to delays and increased costs.

- Regulatory hurdles regarding material properties and emissions increase operational expenses.

These challenges highlight the need for innovation in manufacturing techniques and supply chain management to make these composites more accessible and cost-effective.

Environmental Considerations

The production of carbon-carbon composites impacts the environment through the emission of volatile organic compounds (VOCs). These emissions contribute to ozone formation and smog, affecting ecosystems and human health. However, manufacturers can mitigate these effects by employing thermal or catalytic oxidation devices, which achieve over 99% destruction of harmful emissions. By adopting such strategies, the industry can reduce its environmental footprint while maintaining high production standards.

Future Potential

Innovations in Carbon Fiber Carbon Plate Manufacturing

Recent advancements in manufacturing techniques have significantly enhanced the performance and sustainability of carbon-carbon composites. These innovations focus on improving material properties while reducing environmental impact.

- Chemical recycling and pyrolysis technologies are gaining traction. These methods promote a circular economy by enabling the reuse of composite materials.

- Nanotechnology integration, including graphene and carbon nanotubes, is revolutionizing the industry. These materials improve the strength, thermal conductivity, and durability of carbon composites.

- Green composites are emerging as a sustainable alternative. They utilize renewable resources like natural fibers and bio-resins.

- Lightweight composites now rival steel in strength, offering improved fuel efficiency in transportation.

- Sandwich composites are engineered to absorb more energy during crashes, enhancing safety in automotive and aerospace applications.

These advancements demonstrate the potential of carbon fiber carbon plate technology to meet the growing demand for high-performance materials.

Emerging Applications in Advanced Technologies

Carbon-carbon composites are finding new applications in cutting-edge technologies. Their unique properties make them indispensable in various fields:

- Aerospace components, such as airplane braking systems, rocket nozzles, and re-entry vehicle heat shields.

- Medical devices, where precision and durability are critical.

- Automotive industries, particularly in high-performance vehicles requiring lightweight and heat-resistant materials.

These applications highlight the versatility of carbon-carbon composites in addressing modern engineering challenges.

Role in Sustainability and Green Energy

Carbon-carbon composites play a pivotal role in advancing sustainability and green energy initiatives. Their lightweight nature reduces energy consumption in transportation, while their durability ensures long-lasting performance. In renewable energy, these materials are used in wind turbine blades and photovoltaic systems, contributing to cleaner energy production.

By integrating sustainable practices in manufacturing, the industry can further reduce its environmental footprint. This aligns with global efforts to combat climate change and promote eco-friendly technologies.

The future of carbon-carbon composites lies in their ability to balance performance with sustainability, driving innovation across industries.

Carbon-carbon composites combine carbon fibers and a carbon matrix to deliver unmatched performance. Their properties include high strength-to-weight ratio, thermal stability, and corrosion resistance, as shown below:

| Property | Description |

|---|---|

| High Strength-to-Weight Ratio | Extremely light yet strong, providing comparable strength to metals. |

| Thermal Stability | Maintains properties under extreme temperatures, with low thermal expansion. |

| Corrosion Resistance | Does not rust, ideal for harsh environments. |

| Design Flexibility | Can be molded into complex shapes for innovative designs. |

| Fatigue Resistance | Excellent durability under repetitive stress. |

These materials are revolutionizing industries like aerospace, automotive, and energy by enabling lightweight, durable, and efficient solutions. Continuous advancements in material science, such as nanotechnology and chemical recycling, are enhancing their properties and sustainability. Carbon-carbon composites represent a paradigm shift in engineering, driving innovation and shaping a sustainable future.

FAQ

What makes carbon-carbon composites unique compared to other materials?

Carbon-carbon composites offer unmatched thermal stability, lightweight properties, and high strength. These qualities make them ideal for extreme environments and high-performance applications.

How are carbon-carbon composites used in aerospace?

Aerospace industries use these composites in aircraft brake pads, rocket nozzles, and heat shields. Their lightweight and heat-resistant properties ensure reliability in demanding conditions.

Are carbon-carbon composites environmentally friendly?

Manufacturers increasingly adopt sustainable practices, such as recycling and emission control technologies, to reduce the environmental impact of carbon-carbon composite production.