Quartz bell jars play a pivotal role in semiconductor manufacturing and advanced industrial applications. Their exceptional thermal resistance allows them to endure extreme temperatures without deformation, making them ideal for high-temperature processes. The chemical inertness of quartz ensures durability and prevents contamination, which is critical in sensitive environments. Additionally, their optical clarity facilitates precise monitoring during manufacturing. Whether it’s a standard quartz bell jar or a specialized black quartz bell jar, these components provide unmatched reliability. Industries seeking high-quality solutions often explore quartz bell jar for sale options to meet their stringent requirements. For those looking for convenience, finding a quartz bell jar nearby can streamline the procurement process, ensuring that production schedules are met without delay. The versatility of the glass quartz bell jar further enhances its application across various sectors, making it an essential tool in modern manufacturing.

Key Takeaways

- Essential for semiconductor manufacturing due to their exceptional thermal resistance, allowing them to withstand extreme temperatures without deformation.

- The chemical inertness of quartz prevents contamination, ensuring a pure manufacturing environment critical for high-quality semiconductor devices.

- Optical clarity enables precise monitoring of processes, which is vital for maintaining accuracy and efficiency in production.

- Using quartz bell jars in chemical vapor deposition (CVD) processes ensures uniform thin-film deposition, enhancing the performance of semiconductor layers.

- outperform glass and metals in durability and chemical resistance, making them a cost-effective choice for high-tech applications.

- Their versatility extends beyond semiconductors, supporting industries like photovoltaics and advanced materials processing by providing contamination-free environments.

- Investing in quartz bell jars leads to long-term savings by reducing maintenance costs and ensuring consistent, high-quality outputs.

Key Properties of Quartz Bell Jars

High Thermal Resistance

Exhibit exceptional thermal resistance, making them indispensable in high-temperature industrial processes. Their ability to withstand extreme heat without deforming ensures consistent performance in demanding environments. This property is particularly vital in applications like chemical vapor deposition (CVD), where maintaining structural integrity under intense heat is crucial. The premium quality quartz material used in these jars enhances their durability, allowing them to endure repeated exposure to high temperatures without compromising functionality.

“Quartz’s low thermal expansion and high melting point make it the ideal choice for high-temperature applications,” as noted by industry experts.

This unique thermal stability ensures that quartz bell jars remain reliable even in the most challenging manufacturing conditions.

Chemical Inertness

The chemical inertness of quartz bell jars sets them apart from other materials. Quartz resists reactions with acids, bases, and solvents commonly used in semiconductor fabrication. This resistance ensures the purity of the manufacturing environment, preventing contamination of sensitive substrates. For instance, in plasma etching or vacuum deposition systems, the inert nature of quartz protects the integrity of the chamber and the materials being processed.

Manufacturers rely on this property to maintain the durability and longevity of their equipment. The use of high-purity quartz further enhances this feature, ensuring that the jars remain unaffected by corrosive substances over time.

Optical Clarity and Transparency

Offer unparalleled optical clarity, a feature that proves essential in precision-driven industries. Their transparency allows operators to monitor internal processes visually, ensuring accuracy and efficiency. This capability is particularly critical in semiconductor manufacturing, where even minor deviations can impact the quality of the final product.

The superior clarity of quartz also supports light transmission, making it suitable for applications requiring visual inspection or interaction with light-based technologies. Whether used in vacuum systems or advanced material processing, the transparency of quartz bell jars ensures that processes remain controlled and observable.

Applications of Quartz Bell Jars in Semiconductor Manufacturing

Role in Chemical Vapor Deposition (CVD)

Play a vital role in chemical vapor deposition (CVD), a process essential for creating thin films on semiconductor wafers. These jars provide a stable, high-temperature environment, ensuring the deposition process remains consistent and precise. The high thermal stability of quartz prevents deformation, even under extreme heat, maintaining the integrity of the chamber throughout the operation.

Uniformity in semiconductor layers is critical for device performance. Excel in this aspect by enabling controlled deposition conditions. Their chemical inertness ensures that no unwanted reactions occur during the process, preserving the purity of the materials involved. This combination of stability and precision makes quartz bell jars indispensable in CVD applications.

“Quartz’s ability to withstand high temperatures and resist chemical attack ensures precision and uniformity in thin-film deposition,” as highlighted by industry specialists.

Use in Etching and Coating Processes

Etching and coating processes demand environments free from contamination. Meet this requirement by offering unmatched chemical resistance and durability. During etching, where materials are selectively removed, the inert nature of quartz prevents any interaction with reactive chemicals. This ensures that the process remains uncontaminated and the final product meets stringent quality standards.

In coating applications, quartz bell jars maintain process integrity within vacuum environments. Their optical clarity allows operators to monitor the coating process in real-time, ensuring accuracy and consistency. The robust structure of quartz also withstands the pressures and vacuums required for these advanced manufacturing techniques, making it a preferred choice for such applications.

Ensuring Contamination-Free Environments

Contamination poses a significant risk in semiconductor manufacturing. Address this challenge by preventing particle generation during critical processes. The inert properties of quartz ensure that no impurities are introduced into the manufacturing environment, safeguarding the quality of semiconductor wafers.

Defect-free production is essential for high-performance semiconductor devices. Support this goal by maintaining a clean and controlled environment. Their resistance to chemical reactions and thermal stability further enhances their reliability, making them an integral component in achieving contamination-free manufacturing.

Broader Industrial Applications of Quartz Bell Jars

High-Temperature Processes

Excel in high-temperature processes, where maintaining material stability is critical. Industries rely on these jars during annealing, a heat treatment process that enhances the properties of materials like metals and semiconductors. The exceptional thermal stability of quartz ensures that the jars withstand extreme heat without deforming or degrading. This reliability allows manufacturers to achieve consistent results, even under demanding conditions.

The high melting point of quartz makes it an ideal choice for applications requiring prolonged exposure to elevated temperatures. By resisting thermal expansion, maintain their structural integrity, ensuring process efficiency. This capability supports industries that demand precision and durability in their high-temperature operations.

“Quartz’s ability to endure extreme heat without compromising its structure makes it indispensable in advanced manufacturing,” as noted by material science experts.

Vacuum Systems and Chambers

Play a pivotal role in vacuum systems and chambers, where strength and transparency are essential. These jars create a sealed environment, enabling processes like vacuum deposition and plasma etching. Their robust structure withstands the pressures and vacuums required in these systems, ensuring operational stability.

The optical clarity of quartz enhances its functionality in vacuum environments. Operators can visually monitor processes in real-time, ensuring accuracy and control. This feature proves invaluable in industries such as aerospace and optics, where precision manufacturing is paramount. For instance, in optics, support the production of high-quality lenses and coatings by maintaining contamination-free conditions.

Additionally, the chemical resistance of quartz ensures that the jars remain unaffected by reactive substances used in vacuum systems. This durability extends the lifespan of the equipment, reducing maintenance costs and downtime. The versatility of quartz bell jars makes them a preferred choice for scientific research and industrial applications requiring vacuum-sealed environments.

Advantages of Quartz Bell Jars Over Alternative Materials

Why Quartz Outperforms Glass and Metals

Quartz surpasses both glass and metals in several critical aspects, making it the preferred material for high-tech applications. Its superior thermal resistance ensures that it remains stable under extreme temperatures, unlike glass, which can deform or crack when exposed to intense heat. This property is essential for processes like chemical vapor deposition (CVD) and plasma etching, where maintaining structural integrity is non-negotiable.

“Quartz’s low thermal expansion and high melting point make it the ideal choice for high-temperature applications,” as noted by material science experts.

In addition to thermal stability, quartz exhibits greater chemical inertness and durability compared to metals. While metals may corrode or react with chemicals over time, quartz resists acids, bases, and solvents, ensuring a contamination-free environment. This resistance extends the lifespan of equipment and maintains the purity of sensitive manufacturing processes. Industries that demand precision and reliability consistently choose quartz for its unmatched performance.

Cost vs. Performance Benefits

Offer significant long-term cost savings due to their durability and reliability. Although the initial investment in quartz may be higher than alternative materials, its extended lifespan and reduced maintenance requirements justify the expense. For instance, glass components often require frequent replacements due to their fragility, while metals may degrade in corrosive environments. Quartz, on the other hand, withstands these challenges, minimizing downtime and replacement costs.

The performance benefits of quartz further enhance its value proposition. Its ability to maintain stability under extreme conditions ensures consistent results in demanding applications. This reliability translates to fewer process interruptions and higher-quality outputs, which are critical in industries like semiconductor manufacturing and advanced materials processing.

“Quartz’s properties make it superior to glass and metals in terms of performance and cost-effectiveness,” as highlighted by industry specialists.

By combining exceptional performance with long-term economic advantages, stand out as the optimal choice for high-tech and industrial applications.

The Role of Quartz Bell Jars in High-Tech Industries

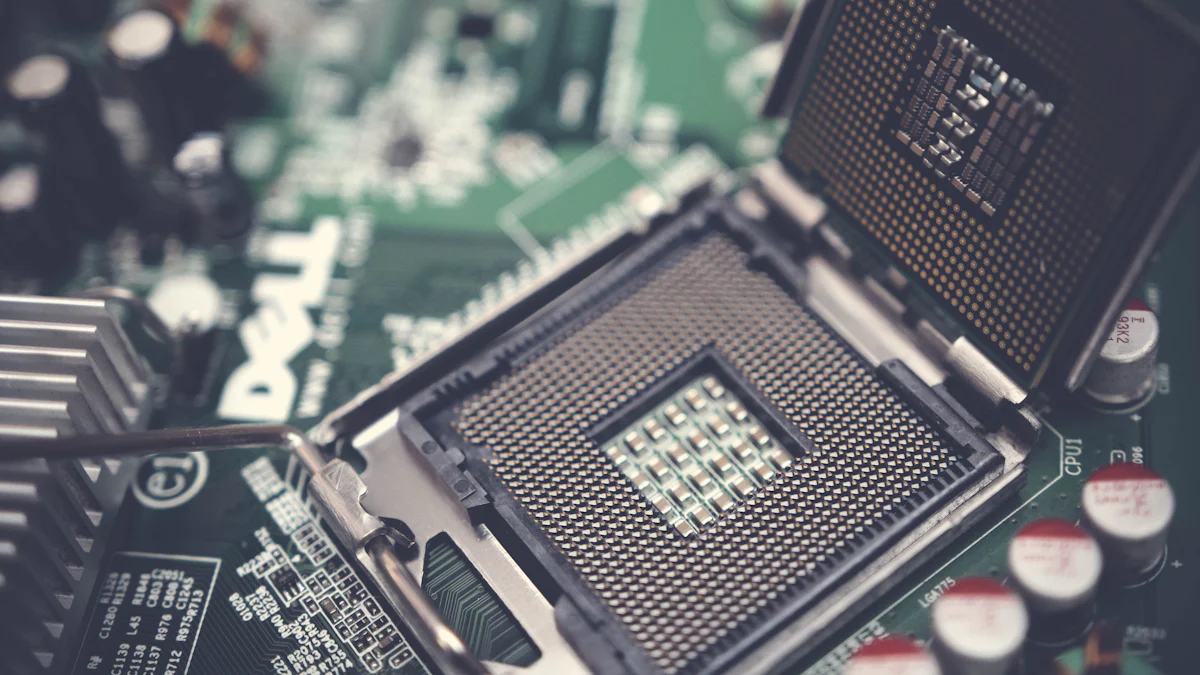

Semiconductor Manufacturing

Play a critical role in semiconductor manufacturing by ensuring precision and maintaining contamination-free environments. Their exceptional chemical inertness prevents unwanted reactions, safeguarding the purity of the manufacturing process. This property is vital for producing high-quality semiconductor devices, where even the slightest impurity can compromise performance.

The optical clarity of quartz bell jars allows operators to monitor processes with accuracy. This transparency ensures that every step, from chemical vapor deposition to plasma etching, meets stringent quality standards. Manufacturers rely on these jars to create defect-free semiconductor wafers, which form the foundation of modern electronic devices.

“Quartz’s superior durability and resistance to chemical attack make it indispensable in semiconductor fabrication,” as noted by Semicorex.

By combining thermal stability, chemical resistance, and optical clarity, support the production of advanced semiconductor technologies.

Photovoltaics and New Energy

In the field of photovoltaics and new energy, enable processes that demand high purity and stability. These jars provide a controlled environment for manufacturing solar cells, ensuring that materials remain uncontaminated during critical stages. The high thermal resistance of quartz supports processes like thin-film deposition, which require consistent performance under extreme temperatures.

Quartz bell jars also contribute to advancements in renewable energy technologies. Their ability to maintain a clean and precise environment enhances the efficiency of photovoltaic devices. For instance, during the production of silicon-based solar cells, quartz ensures that the materials retain their integrity, resulting in higher energy conversion rates.

The durability of quartz bell jars reduces maintenance needs, making them a cost-effective solution for industries focused on sustainable energy. Their role in enabling high-purity manufacturing processes positions them as a cornerstone in the development of innovative energy solutions.

Advanced Materials Processing

Are indispensable in advanced materials processing, where precision and material integrity are paramount. These jars support the development of cutting-edge materials like silicon carbide and ceramics, which are essential for high-performance applications. The chemical inertness of quartz ensures that no impurities interfere with the processing of these materials.

In high-temperature environments, qmaintain their structural integrity, allowing manufacturers to achieve consistent results. Processes such as annealing and sintering benefit from the thermal stability of quartz, which prevents deformation and ensures uniformity in material properties.

“Quartz’s ability to create a vacuum-sealed, contamination-free environment makes it ideal for advanced materials research,” according to Stanford Advanced Materials.

By providing a reliable and controlled environment, quartz bell jars enhance process efficiency and support the creation of innovative materials that drive technological progress.

Quartz bell jars have become essential in semiconductor manufacturing and other high-tech industries due to their exceptional properties. Their thermal resistance ensures stability in extreme temperatures, while their chemical inertness prevents contamination during sensitive processes. The optical clarity of quartz allows precise monitoring, making it invaluable for applications requiring accuracy and control. These qualities, combined with unmatched durability, position quartz bell jars as the superior choice over alternative materials. By enabling efficient, reliable, and contamination-free operations, they play a pivotal role in advancing modern technology and industrial innovation.

FAQ

What are Quartz Bell Jars used for in semiconductor manufacturing?

Serve as essential components in semiconductor manufacturing. They are primarily used in deposition techniques such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and atomic layer deposition (ALD). These processes require precise and uniform thin-film deposition on semiconductor substrates. Quartz bell jars provide the controlled environment necessary to achieve this level of precision.

“Quartz’s thermal stability and chemical inertness make it indispensable for deposition processes,” according to industry experts.

Why is quartz preferred over other materials for bell jars?

Quartz outperforms materials like glass and metals due to its exceptional properties. Its high thermal resistance ensures stability under extreme temperatures, while its chemical inertness prevents reactions with corrosive substances. Unlike glass, quartz resists deformation under heat, and unlike metals, it does not corrode or contaminate sensitive environments. These qualities make quartz the material of choice for high-tech applications.

How do quartz bell jars ensure contamination-free environments?

Maintain contamination-free environments by leveraging their chemical inertness and purity. They resist reactions with acids, bases, and solvents, ensuring no impurities are introduced during manufacturing. This property is critical in processes like plasma etching and vacuum deposition, where even minor contamination can compromise the quality of semiconductor wafers.

What role do quartz bell jars play in chemical vapor deposition (CVD)?

Create a stable, high-temperature environment essential for chemical vapor deposition (CVD). They enable the precise deposition of thin films on semiconductor wafers by maintaining structural integrity under intense heat. Their chemical resistance ensures that no unwanted reactions occur, preserving the purity of the materials involved.

“The stability and inertness of quartz are key to achieving uniformity in semiconductor layers,” as noted by material scientists.

Can quartz bell jars be used in vacuum systems?

Yes, quartz bell jars are ideal for vacuum systems. Their robust structure withstands the pressures and vacuums required in these environments. Additionally, their optical clarity allows operators to monitor processes in real-time, ensuring accuracy and control. These features make quartz bell jars indispensable in industries like aerospace, optics, and advanced materials processing.

Are quartz bell jars suitable for high-temperature processes?

Excel in high-temperature processes due to their exceptional thermal stability. They can endure extreme heat without deforming, making them ideal for applications like annealing and sintering. Their ability to resist thermal expansion ensures consistent performance, even under prolonged exposure to elevated temperatures.

How do quartz bell jars contribute to advanced materials processing?

Quartz bell jars support advanced materials processing by providing a reliable and controlled environment. Their chemical inertness prevents contamination, while their thermal stability ensures consistent results in high-temperature processes. These qualities make them essential for developing innovative materials like silicon carbide and ceramics.

What industries benefit from using quartz bell jars?

Applications in several high-tech industries, including:

- Semiconductor manufacturing: Ensures precision and contamination-free environments.

- Photovoltaics and renewable energy: Supports the production of high-purity solar cells.

- Aerospace and optics: Enables precision manufacturing in vacuum-sealed environments.

- Advanced materials research: Facilitates the development of cutting-edge materials.

How do quartz bell jars enhance process efficiency?

Enhance process efficiency by combining durability, thermal stability, and chemical resistance. Their ability to maintain a clean and controlled environment reduces downtime and maintenance costs. This reliability ensures consistent results, which are critical for industries demanding precision and high-quality outputs.

Where can one find high-quality quartz bell jars?

High-quality quartz bell jars are available through specialized manufacturers and suppliers. Companies like Ningbo Miami Advanced Material Technology Co., LTD offer a range of quartz products tailored to meet the stringent requirements of industries like semiconductors, photovoltaics, and advanced materials processing.